Tea seed kernel metal cleaning device

A cleaning device and metal technology, applied in the direction of magnetic separation, solid separation, fat generation, etc., can solve the problems of difficult cleaning, shutdown, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

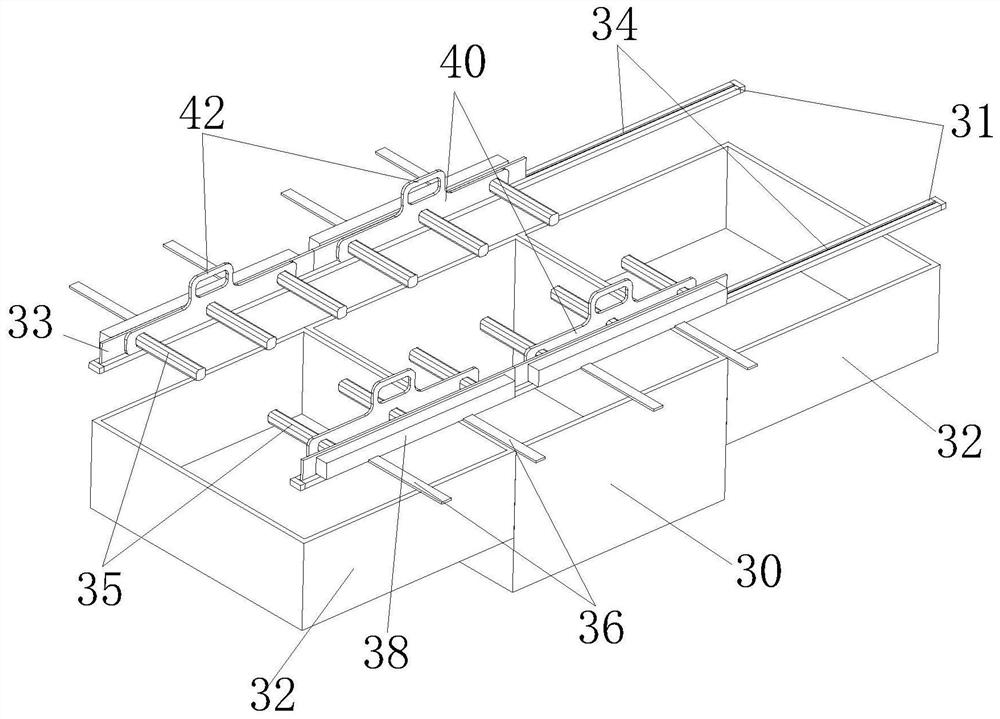

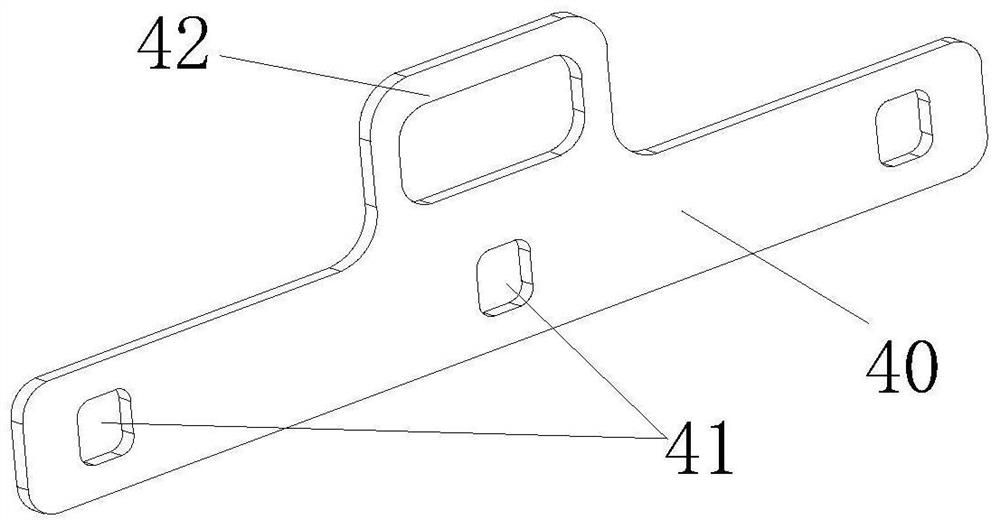

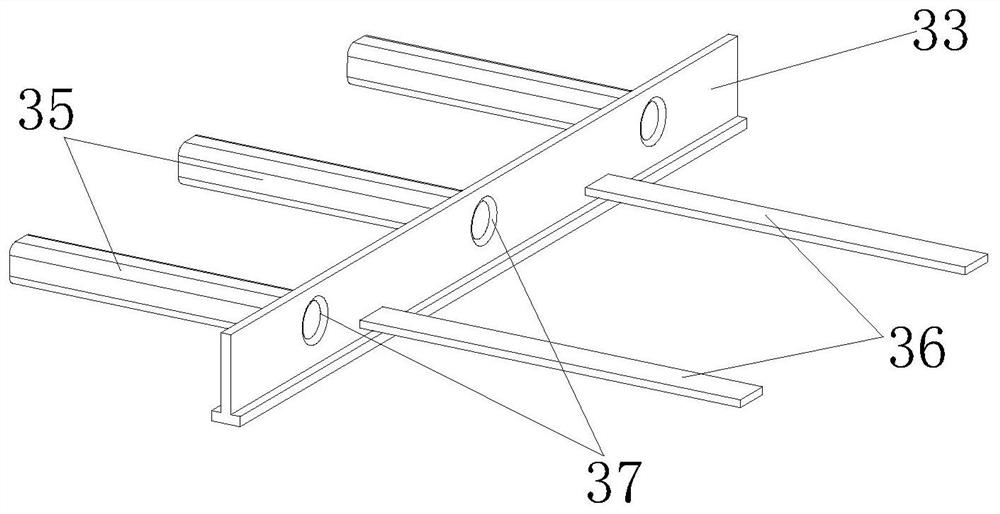

[0021] Such as Figure 1-Figure 4 As shown, a metal cleaning device for tea seeds includes a hopper 30 and two rails 31. A metal recovery tank 32 is respectively provided on both sides of the hopper 30. The two rails 31 are parallel to each other. There are two sets of metal adsorption mechanisms that are arranged in sequence and can slide along the rail 31 and pass above the receiving hopper 30 and the metal recovery tank 32. The metal adsorption mechanism includes a base that is arranged on the rail 31 and can only slide along the rail 31 33, the track 31 is provided with a T-shaped slot 34 arranged along the track 31, the base 33 is a T-shaped structure and the wider side of the base 33 is sleeved in the T-shaped slot 34, the base 33 Vertically fixedly be provided with three guide rails 35 and two guide rails 36 that are arranged horizontally, the guide cover 35 is a hollow structure, and the cover 35 and the guide rails 36 are positioned at the two sides of the base 33 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com