Honeycomb paperboard forming process

A technology of honeycomb paperboard and forming process, which can be applied in the direction of paperboard articles, etc., and can solve the problems of affecting the quality of the board, poor adhesion of the paper core, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

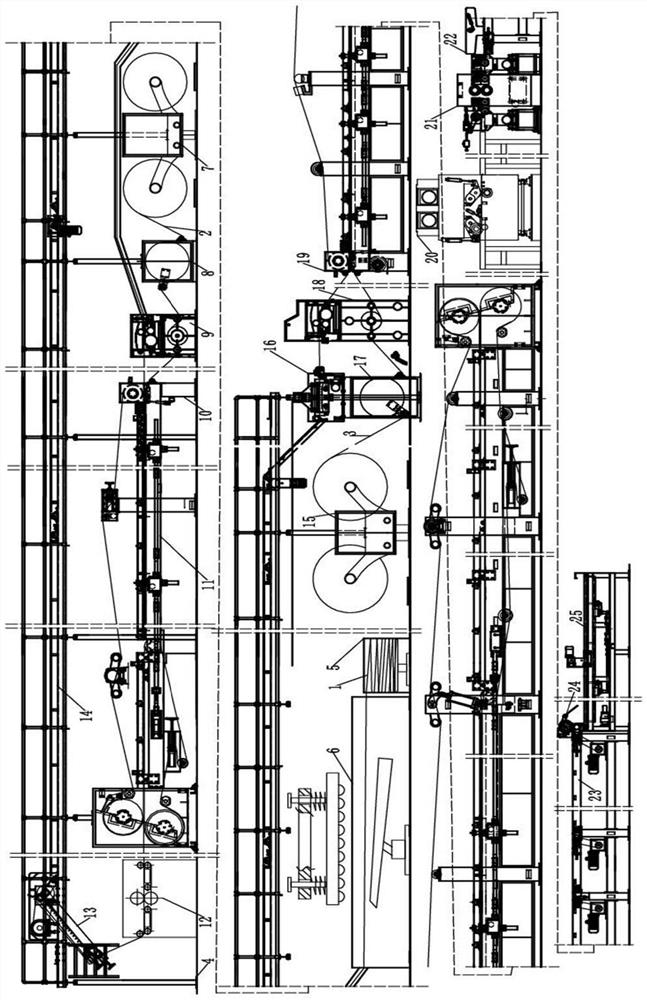

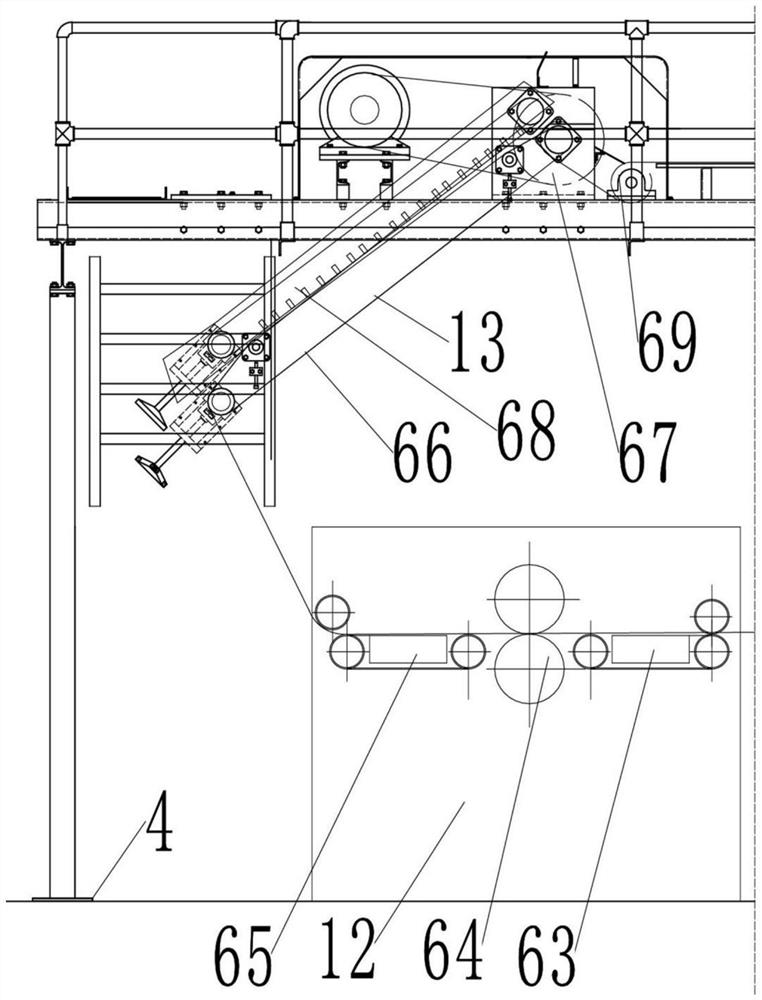

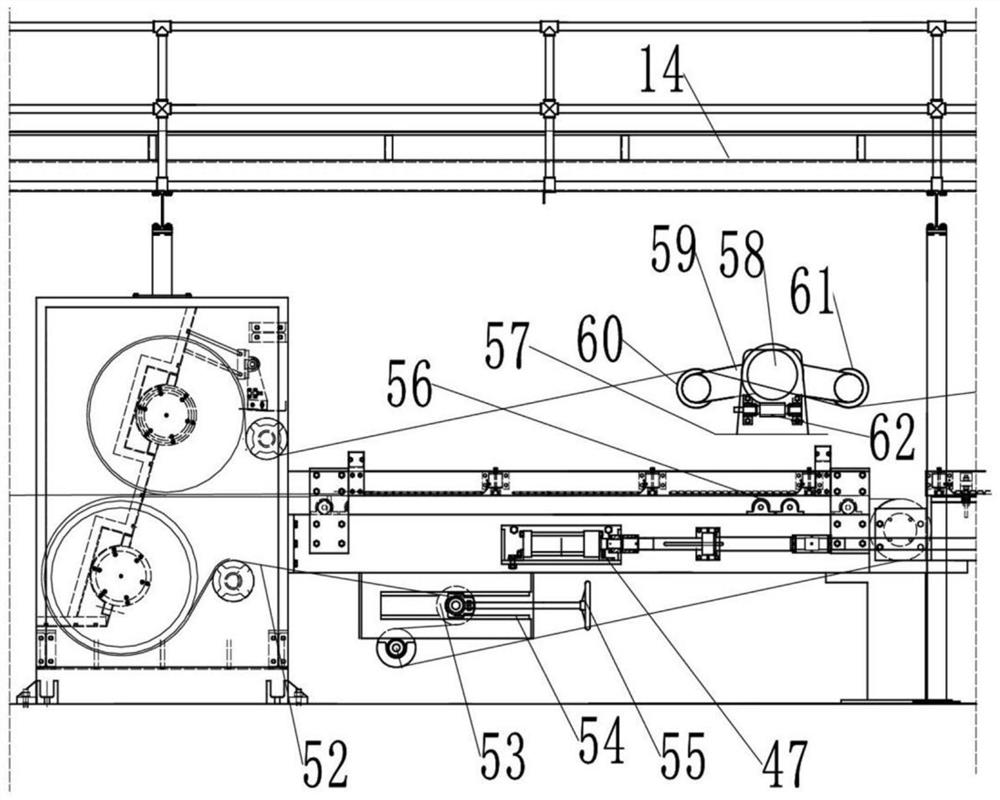

[0008] Such as Figure 1-19 As shown, the honeycomb paperboard forming device of this embodiment is used to bond the surface paper tape 2 and the face paper tape 3 on the two surfaces of the honeycomb paper tape 1; Surface paper feeding device 7, surface paper preheating device 8, first gluing machine 9, first bonding device 10, first heating device 11, first edge dividing device 12, lifting corner device 13, which are connected to the process , conveying bridge device 14, tissue feeding device 15, tension device 16, tissue preheating device 17, double-sided gluing device 18, drying and shaping device 19, paper slitting machine 20, paper cross cutting machine 21, printing Labeling machine 22, output transmission device 23, turning device 24, palletizer 25;

[0009] Storage lifting platform 26 is stored in honeycomb paper storage box 5, and honeycomb paper strip 1 is placed on storage lifting platform 26.

[0010] Shaping device 6 comprises the left side of honeycomb paper st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com