A fully automatic glass inspection conveying system

A conveying system, fully automatic technology, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of different scales, large floor space, glass cuts, etc., to reduce conveying failure and floor space , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

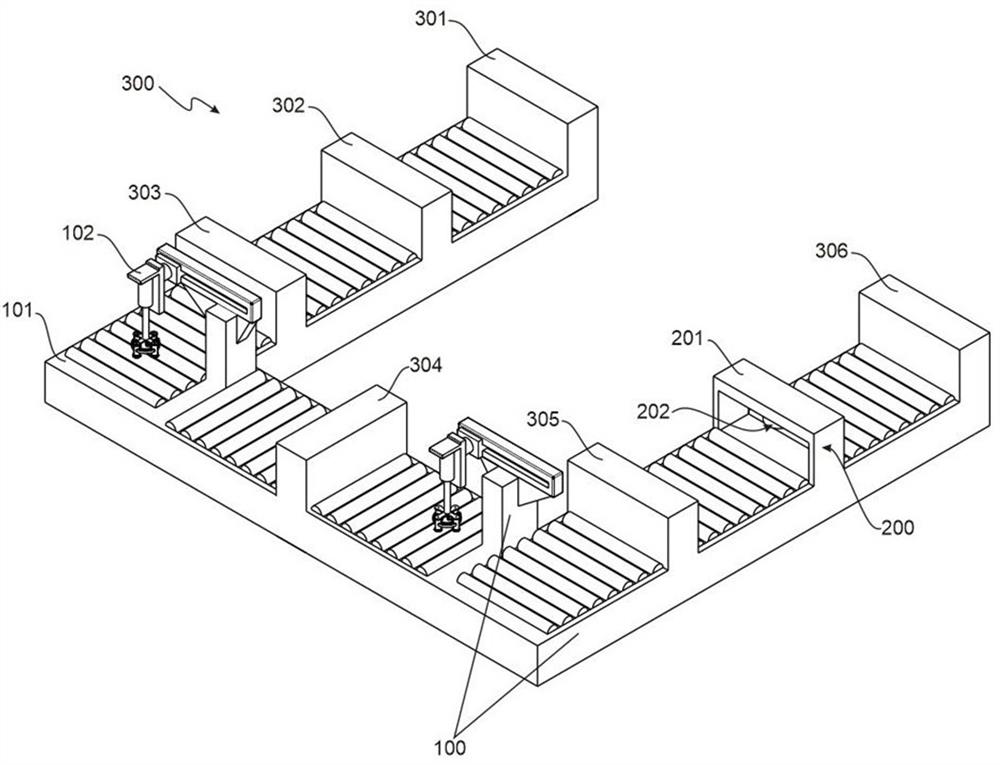

[0027] refer to figure 1 , which is the first embodiment of the present invention, this embodiment provides a fully automatic glass inspection conveying system, the fully automatic glass inspection conveying system includes a conveying unit 100, a detection unit 200 and a production unit 300, the conveying unit 100 includes conveying The machine tool 101 and the automatic glass product output device 102 are connected to the detection unit 200 and the production unit 300; the detection unit 200 includes an inspection machine 201, and the two ends of the inspection machine 201 are respectively connected to the conveying machine tool 101, and an inspection device is installed inside 202; the production unit 300 sequentially includes a manufacturing machine 301, a cutting machine 302, an edger 303, a printing machine 304, a tempering machine 305 and a packaging machine 306, and the detection unit 200 is connected between the tempering machine 305 and the packaging between machines...

Embodiment 2

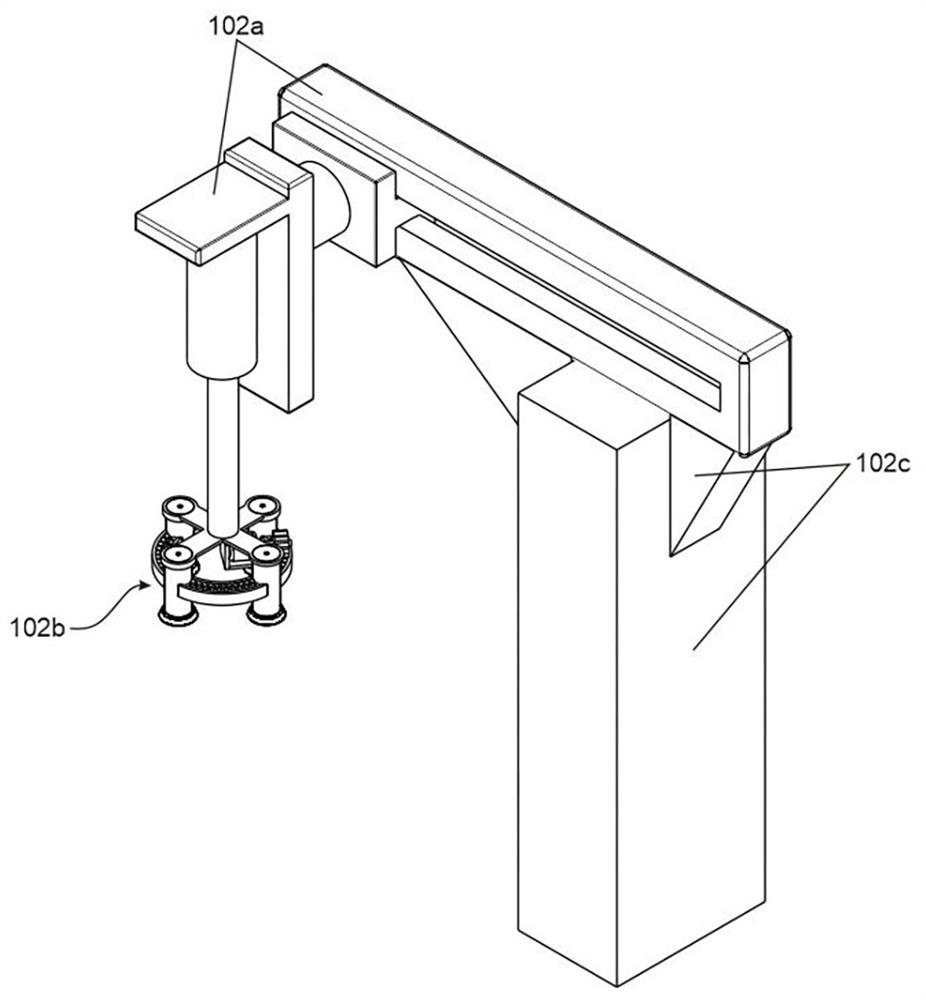

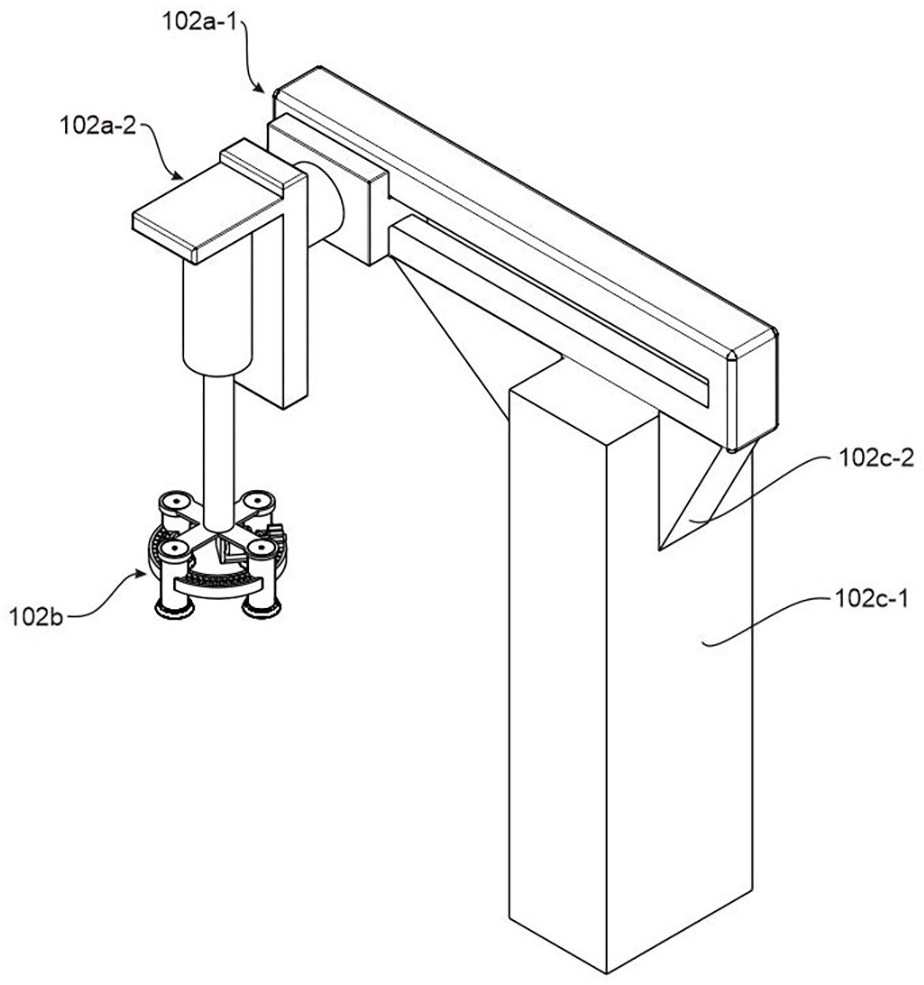

[0031] refer to Figure 2~4 , which is the second embodiment of the present invention, which differs from the first embodiment in that a plurality of conveying machine tools 101 and the automatic glass product output device 102 are set, and the automatic glass product output device 102 includes a sliding module 102a, a delivery module 102b and a support module 102c, the slide module 102a includes a horizontal slide assembly 102a-1 and a vertical slide assembly 102a-2, the delivery module 102b includes a support 102b-1 and a grabbing assembly 102b-2, the The grasping component 102b-2 includes a column 102b-21, a suction cup 102b-22 and a ring 102b-23, and the support module 102c includes a third support 102c-1 and a triangular plate 102c-2.

[0032] Specifically, multiple conveying machine tools 101 are provided to connect the production unit 300 and the detection unit 200 in a U-shaped arrangement to reduce the limitation of the machine footprint on the glass factory.

[0033...

Embodiment 3

[0037] refer to Figure 5~7 , is the third embodiment of the present invention, which is different from the first two embodiments in that: the transport module 102b further includes gears 102b-26 and motors 102b-27.

[0038] Specifically, the transport module 102b is also provided with a gear 102b-26 matched with the convex tooth 102b-25, and a motor 102b-27 connected with the gear 102b-26, and the motor 102b-27 is fixed on the On the bracket 102b-1, the motor 102b-27 drives the gear 102b-26 to rotate, and then the ring 102b-23 matched with the gear 102b-26 rotates, and the suction cup 102b-22 When sucking and releasing the glass, avoid sudden changes in the force generated by the suction cup 102b-22, causing the glass to break.

[0039] Further, the column 102b-21 is provided with a first through hole M1, a plurality of second through holes M2 are evenly distributed on the ring 102b-23, and balls 102b corresponding to the column 102b-21 are distributed at the bottom -24, by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com