Soft-touch polyolefin composite material as well as preparation method and application thereof

A composite material and polyolefin technology, which is applied in the field of soft-touch polyolefin composite materials and its preparation, can solve the problems of control and polypropylene composite materials that cannot simultaneously achieve flexural modulus and Shore hardness, and achieve good tactility and cost performance The effect of high and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A soft-touch polyolefin composite material, comprising the following components: polyethylene; polypropylene; thermoplastic elastomer; filler; compatibilizer;

[0073] The preparation method of the above-mentioned soft-touch polyolefin composite material comprises the following steps:

[0074] S1. Mix polyethylene, polypropylene and compatibilizer in a high mixer for 3 minutes, then add other additives, and mix for 2 minutes at a speed of 500 rpm, and mix evenly to obtain a premix;

[0075] S2. The premix is added through the feed port of the twin-screw extruder, and the filler is added from the side feed port by a side feeder, and then melted and extruded. The temperature of each zone of the screw is 190 ° C ~ 230 ° C, and it is made by vacuum granulation Soft-touch polyolefin composite.

Embodiment 1~16

[0077] A soft-touch polyolefin composite material, comprising the following components: polyethylene; polypropylene; thermoplastic elastomer; filler; compatibilizer;

[0078] The preparation method of the above-mentioned soft-touch polyolefin composite material is the same as that in Example 1.

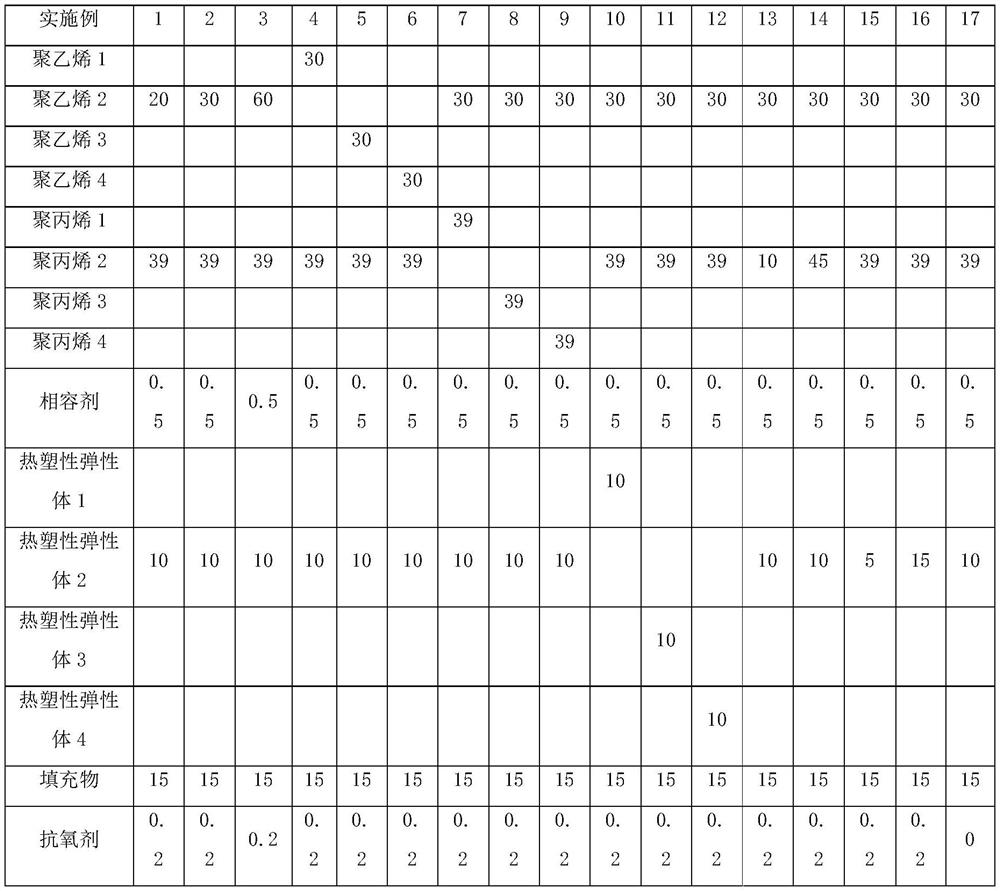

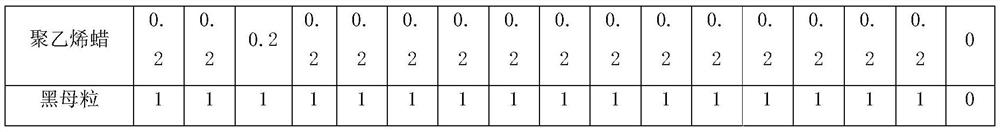

[0079] The content of each component of the polyolefin composite material of the embodiment of table 1 (by mass fraction / part)

[0080]

[0081]

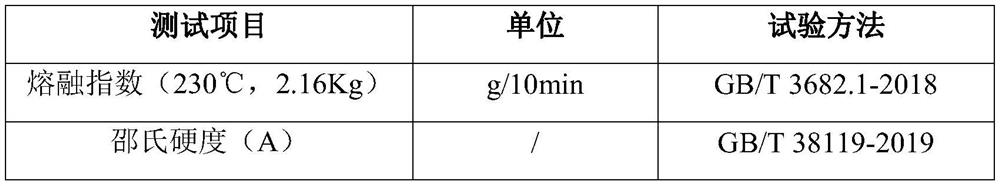

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com