Shearing mechanism for mask melt-blown cloth production

A technology of meltblown cloth and masks, which is applied in the field of cutting mechanism based on the production of mask meltblown cloth, which can solve the problems of refractory blown cloth, transmission belt damage, sticking, etc., and achieve the effect of increasing cutting efficiency and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

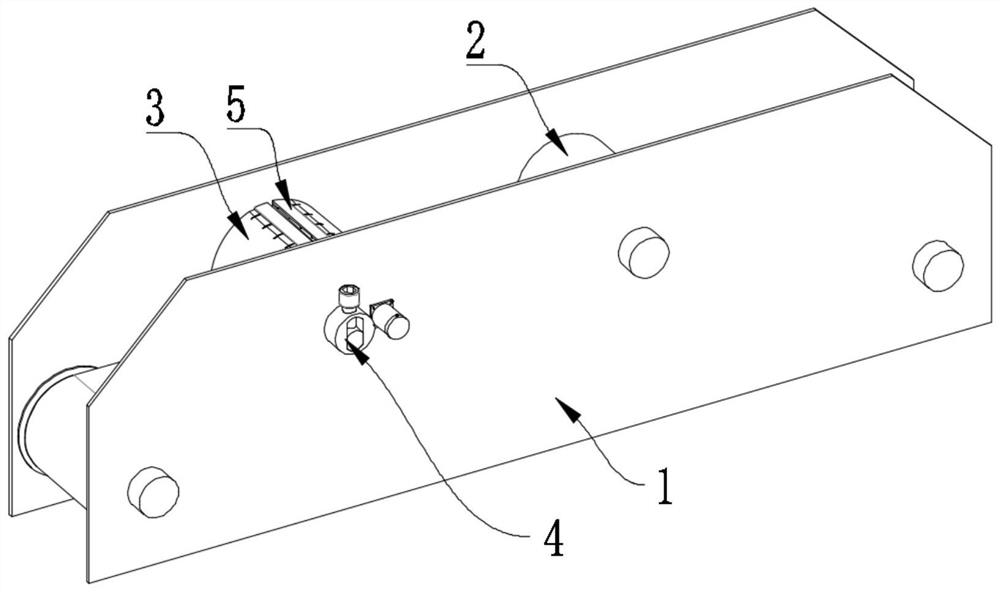

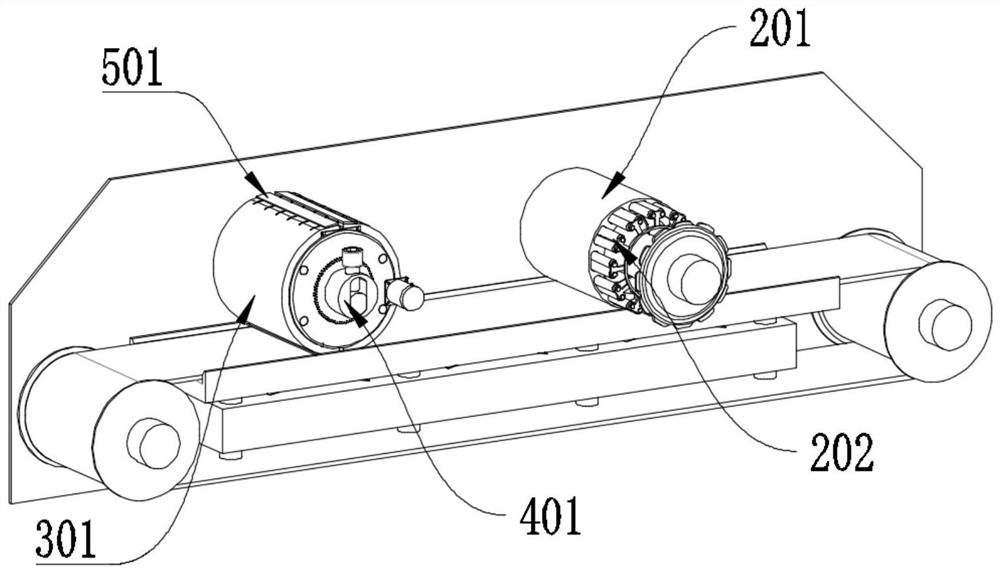

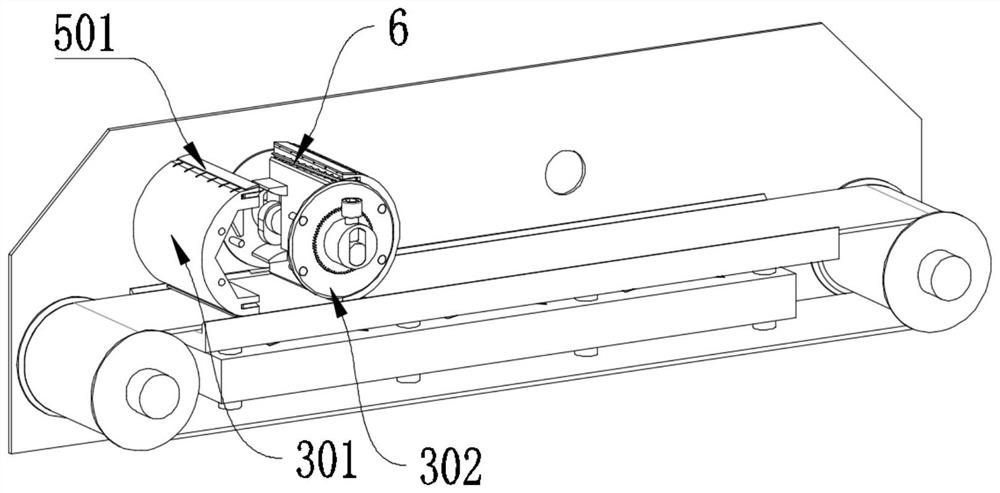

[0034] as attached figure 1 to attach Figure 7 Shown:

[0035] The invention provides a shearing mechanism based on the production of mask meltblown cloth, including a bearing structure 1; a transmission belt is wound on the bearing structure 1, and an auxiliary structure 2 is installed on the right side of the transmission belt; the left side of the auxiliary structure 2 is provided with a wheel body structure 3; the front and rear ends of the wheel structure 3 are rotated and installed with an installation structure 4; the outer wall of the wheel structure 3 is slidingly installed with a tensile structure 5; the inside of the tensile structure 5 is installed with a cleaning structure 6; the wheel structure 3 A cut-off structure 7 is installed slidingly inside.

[0036] Wherein, the carrying structure 1 also includes a carrying plate 101 and a spring plate 102. The bottom of the carrying plate 101 is provided with downward vertical mounting columns, and each group of mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com