Concrete pavement vibration robot based on track assembly and track assembly thereof

A concrete pavement and robot technology, applied in the direction of roads, roads, road repairs, etc., can solve the problems of affecting the vibration effect, filling holes, and cement is easy to dry and stick outside the vibration device, so as to improve the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

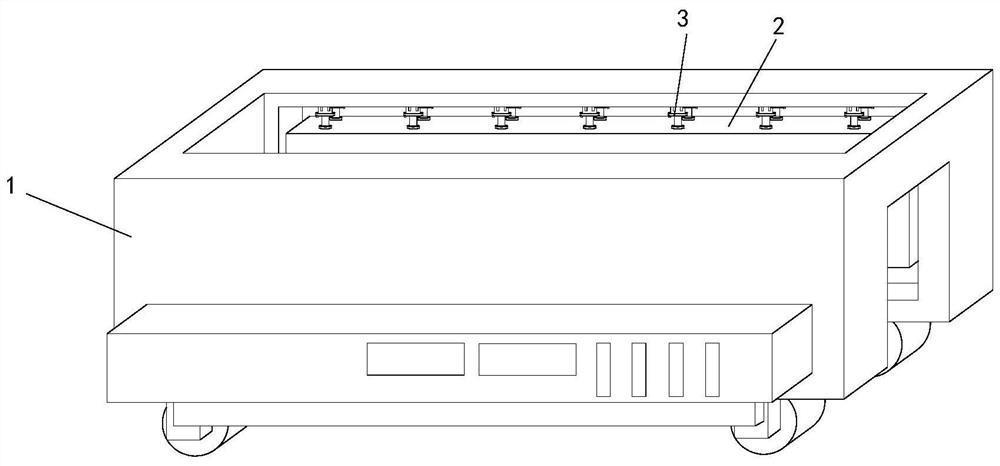

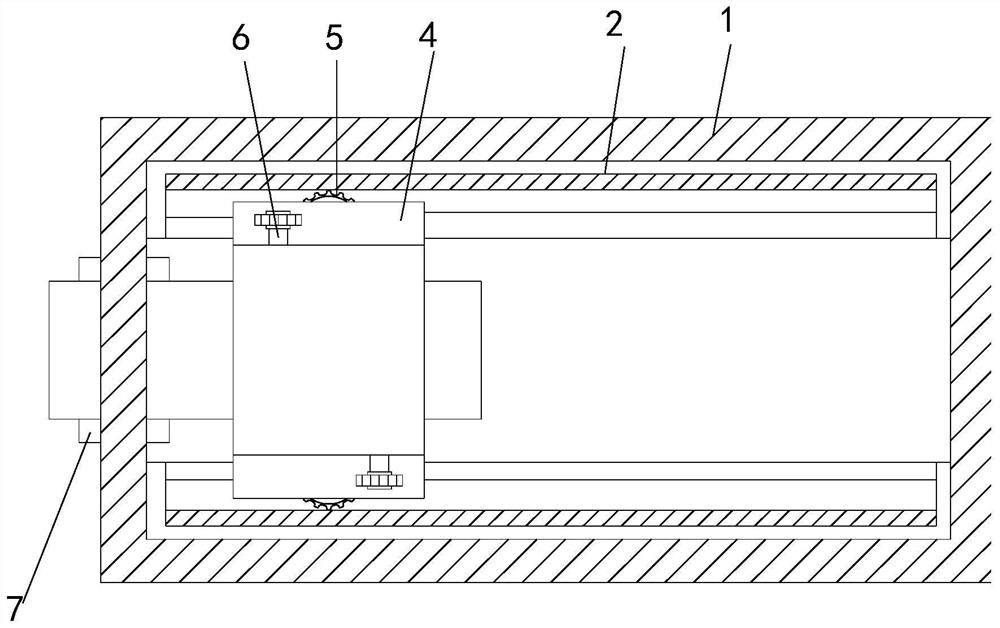

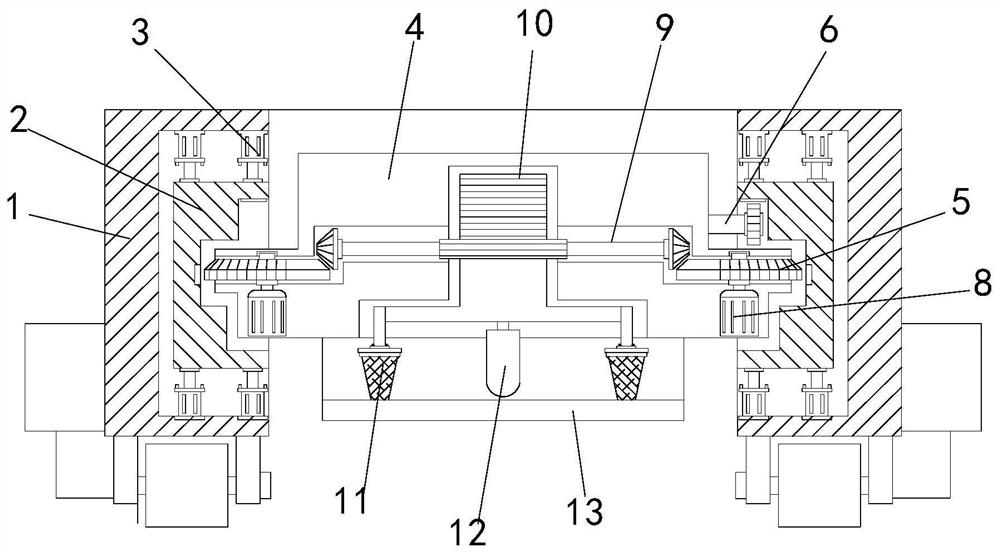

[0030] see Figures 1 to 8 , a planar and three-dimensional structure schematic diagram of a concrete pavement vibration robot based on rail components and its rail components.

[0031] A concrete road vibration robot based on rail components, comprising a device main body 1, a moving track 2 is installed inside the device main body 1, a mobile platform 4 is installed inside the device main body 1, driving gears 5 are installed on both sides of the mobile platform 4, and the mobile platform 4. A lower pressing plate 13 is installed at the lower end, and a lower moving plate 10 is installed at the middle end of the moving platform 4. The lower end of the lower moving plate 10 is connected with an oscillating device 11. The moving platform 4 is arranged inside the moving track 2, and the lower end of the driving gear 5 is connected with a driving motor. 8.

[0032] In specific implementation, only half of the outer side of the driving gear 5 is provided with gear teeth, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com