Determination method of copper, tin and bismuth content in lead smelting solid waste with high silver content

A determination method and lead smelting technology, applied in the determination of tin and bismuth content, copper field, can solve the problems of complex composition, turbid solution, inability to completely eliminate the phenomenon of sample hydrolysis, etc., to eliminate the interference of non-target elements, and the analysis results are accurate , The effect of simple sample handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The preparation method of the sample blank solution is as follows: carrying out alkali melting treatment without adding the lead smelting solid waste, and then using the mixed solution for leaching to obtain the sample blank solution.

[0059] In an optional embodiment, during the determination, the working conditions of the inductively coupled plasma emission spectrometer are specifically:

[0060] RF power 1000W -1200W, plasma air flow 15.0L / min, auxiliary air flow 1.50 L / min, atomizing air flow 0.60L / min -0.70L / min, observation height 4mm -8mm.

[0061] Optionally, the RF power can be any value between 1000W, 1100W, 1200W and 1000W-1200W; the atomizing gas flow rate can be 0.60L / min, 0.65L / min, 0.70L / min and 0.60L / min- Any value between 0.70L / min; observation height can be any value between 4mm, 5mm, 6mm, 7mm, 8mm and 4mm-8mm.

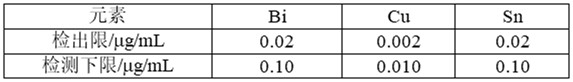

[0062] In an optional embodiment, during the determination, the wavelengths of the analyzed elements are: 327.395 nm for copper, 189.925 nm...

Embodiment 1-5

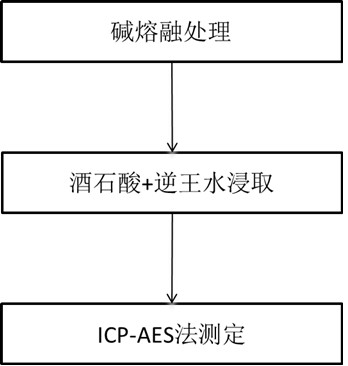

[0068] Take 5 samples (silver content between 0.5% and 20%), and measure them according to the following method (the flow chart is as follows: figure 1 shown):

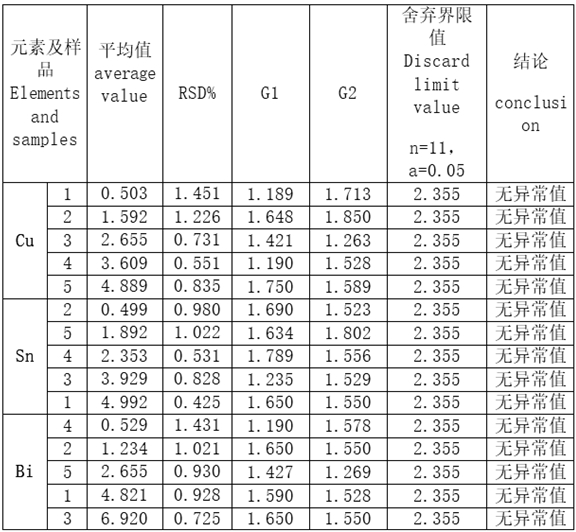

[0069] (1) Decomposition of the sample: Accurately weigh 0.2000g of the sample and mix it in a 25mL corundum crucible with about 1g of sodium peroxide at the bottom, then cover with about 1g of sodium peroxide, and place it in a muffle furnace heated to 700°C Keep the temperature and melt for 20 minutes, take out the crucible, let it cool slightly, put the crucible into a 250mL beaker filled with 5mL tartaric acid (200g / L) and 25mL inverse aqua regia, and wait until the violent action stops the melt falling off, then use Wash out the crucible with hot 2% hydrochloric acid, transfer it to a 100mL volumetric flask after cooling, and dilute to the mark with water. Prepare the sample blank solution according to the above method (without adding the sample, directly melt it with sodium peroxide and then leaching it). Take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com