Equipment and method for determining height of semiconductor structure

A semiconductor and advanced technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, electrical components, etc., it can solve the problems of limited measurement quantity, large measurement error, poor measurement stability, etc., to improve sealing, Improved balance and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

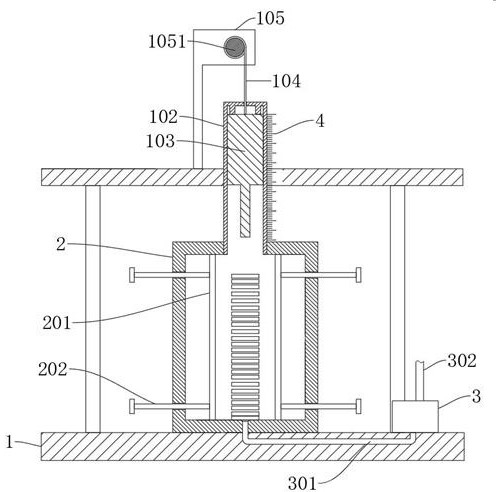

[0039] refer to Figure 1-8 , the equipment used to determine the height of the semiconductor structure, including a mounting frame 1, also includes: a negative pressure box 2, fixedly connected to the mounting frame 1, wherein, one side of the negative pressure box 2 is provided with an opening 306; the box door 203, rotating Connected to the opening 306; the sleeve 102 is fixedly connected to the top of the negative pressure box 2, and one end communicates with the negative pressure box 2, wherein the sleeve 102 is made of transparent material; the measuring scale 4 is arranged on the sleeve 102; the measuring rod 103, slidingly connected in the sleeve 102; stay rope 104, one end is fixedly connected to the top of the measuring rod 103, and the other end runs through the outside of the sleeve 102; the sliding plate 201 is symmetrically slidingly connected in both sides of the negative pressure box 2; the negative pressure pump 3. It is fixedly connected to the installation f...

Embodiment 2

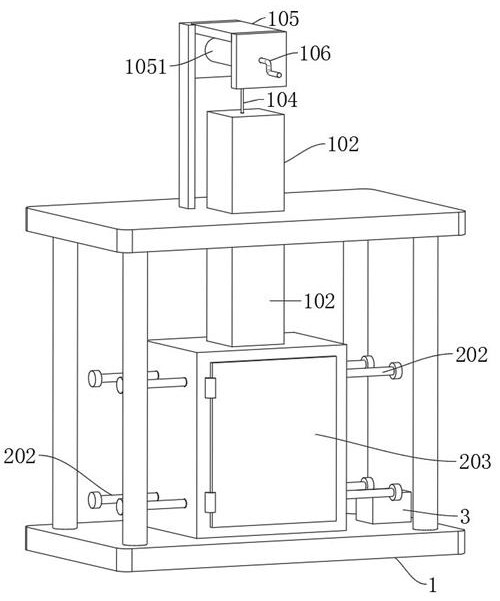

[0054] refer to figure 1 , 2 and 6, which are basically the same as in Embodiment 1, furthermore: a guide rod 202 is fixedly connected to the sliding plate 201, and the end of the guide rod 202 away from the sliding plate 201 slides through and slides on the negative pressure box 2;

[0055] The guide rod 202 can provide a position-limiting guiding effect on the sliding plate 201 when sliding, so as to prevent the sliding plate 201 from being unable to slide due to uneven force when sliding;

[0056] After the measurement is completed, open the box door 203, take out the semiconductor, and then push the two sets of sliding plates 201 away from each other to expand the area for placing the semiconductor next time.

Embodiment 3

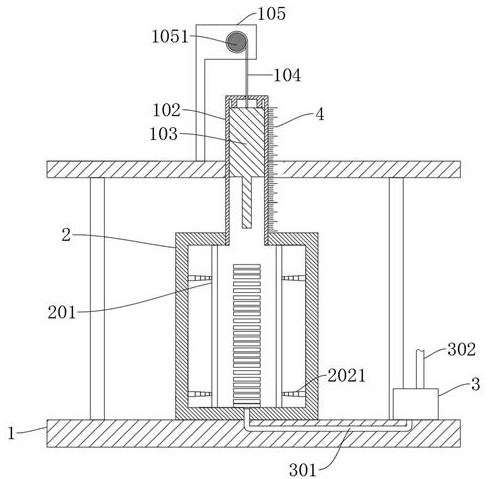

[0058] refer to image 3 , which is basically the same as in Embodiment 1, furthermore: the sliding plate 201 is fixedly connected to a multi-stage telescopic rod 2021, and the end of the multi-stage telescopic rod 2021 away from the sliding plate 201 is fixedly connected to the inner wall of the negative pressure box 2;

[0059] When the sliding plate 201 slides, the multi-stage telescopic rod 2021 is pulled to elongate, and the multi-stage telescopic rod 2021 also plays a role of limiting and guiding the sliding plate 201;

[0060] After the measurement is completed, open the box door 203, take out the semiconductor, and push the two sets of sliding plates 201 away from each other. When the sliding plates 201 are pushed, the multi-stage telescopic rod 2021 will shrink accordingly;

[0061] However, the multi-stage telescopic rod 2021 is arranged in the negative pressure box 2 and does not penetrate the negative pressure box 2, so that the airtightness of the negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com