Double-spoke column spoke superconducting cavity and manufacturing method thereof

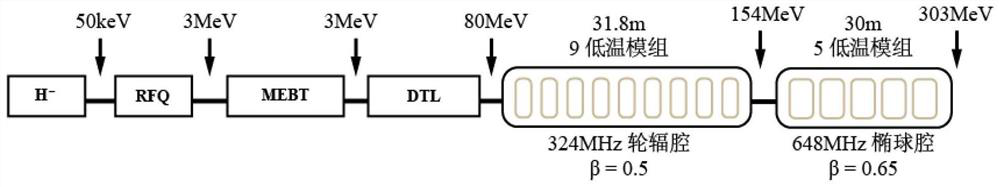

A superconducting cavity and wheel-spoke technology, applied in accelerators, electrical components, etc., can solve the problems of large physical size, complex structure, and difficulty in forming parts of double-spoke column-spoke cavity parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] 1. The mechanical structure design of the spoke cavity of the double spoke post of the present invention.

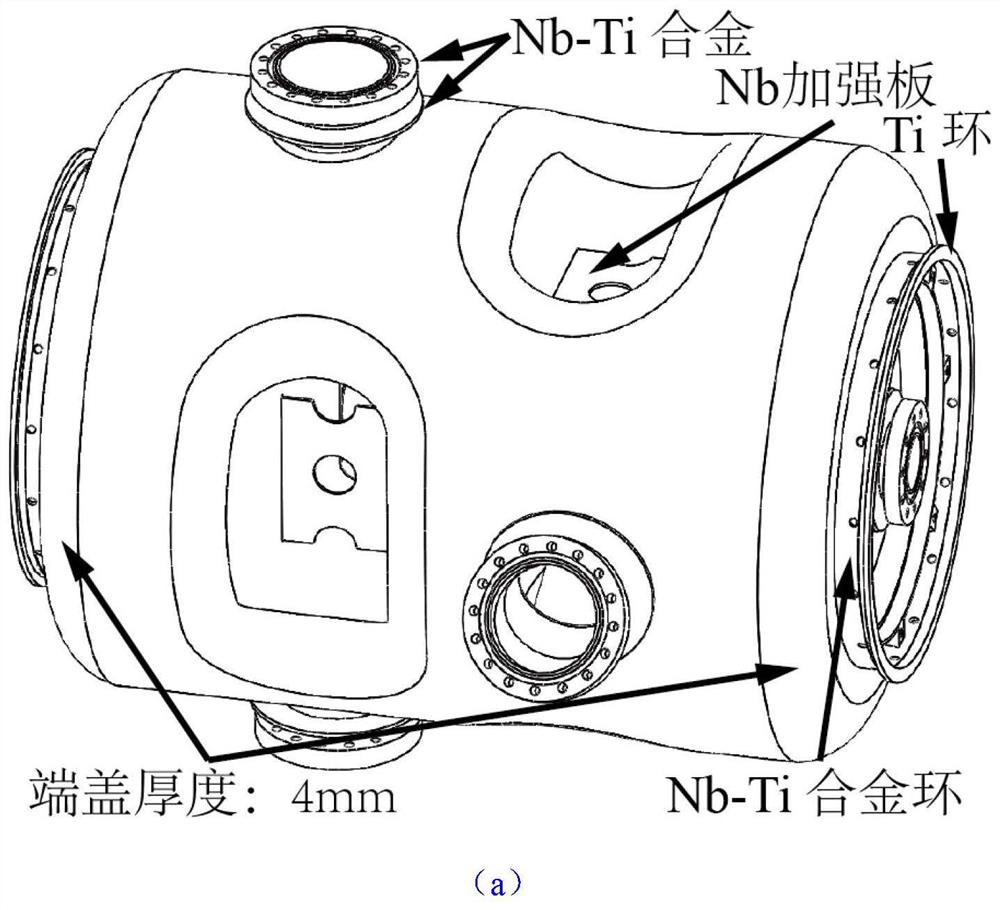

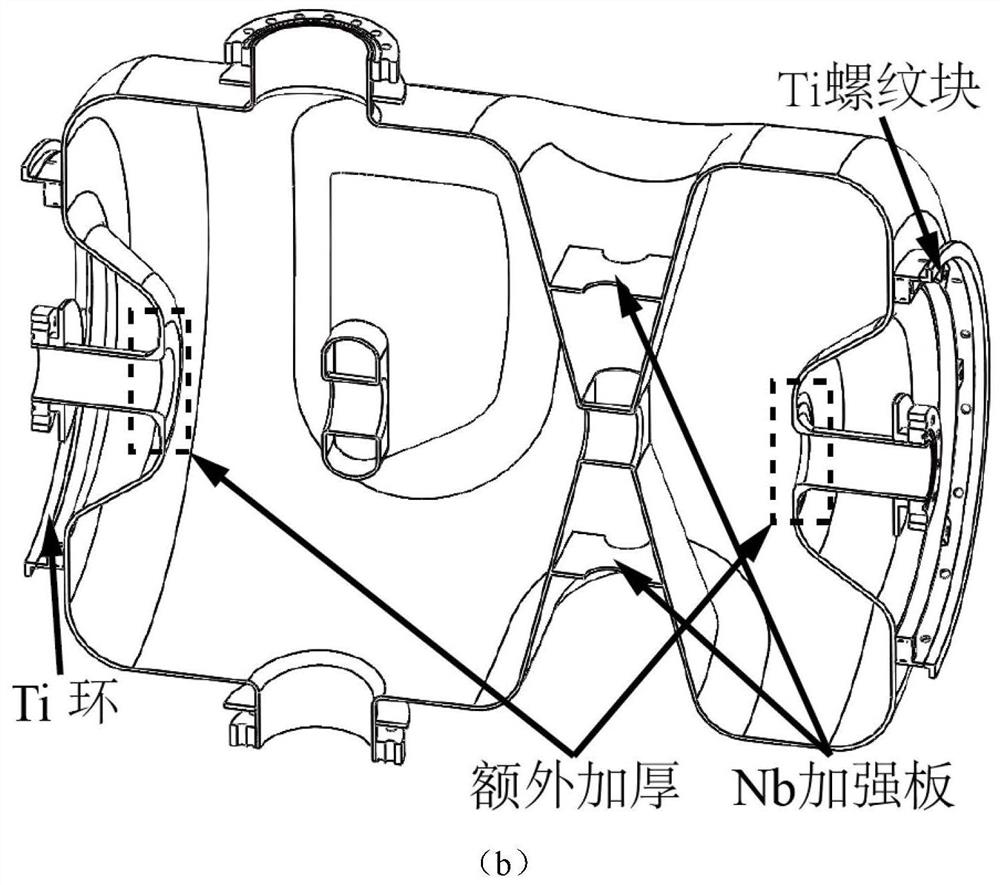

[0056] In the present invention, the mechanical structure of the spoke cavity of the double spoke post is as follows: figure 2 As shown, the thickness of the cavity body is 3mm, and the thickness of the end cover is 4mm. The chamber main body and end cover parts are made of niobium (Nb) material, each opening flange is made of niobium-titanium (Nb-Ti) alloy material, and there are threaded holes on the titanium (Ti) threaded block, which is responsible for the connection between the chamber and the chamber tooling. The titanium ring, the niobium-titanium alloy ring, and the titanium threaded block are welded together to play the role of welding connection of different materials. The central openings of two adjacent cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com