Space gridding printing method of 3D printing sand mold

A space grid, 3D printing technology, applied in the direction of mold, core, mold components, etc., can solve the problems of unsatisfactory compaction effect, large amount of binder, easy to appear pores, etc., to shorten the baking time, Reduces gas production and improves breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The operation process and parameters of the spatial grid printing method of a 3D printing sand mold are as follows:

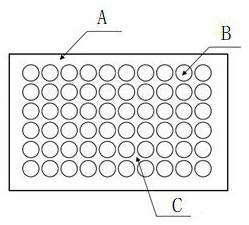

[0028] The size of the sand mold is 800mm×800mm, the height is 150mm, and the upper part is an arc surface structure of R=500mm, such as figure 1 shown.

[0029] The first step is to leave a solid wall thickness of 80 mm at the sand mold boundary according to the size of the sand mold, and divide the rest of the space into grids. Use a sphere with a diameter of 6 mm to divide the inner space of the sand mold into each sphere space grid cavity, and each sphere space A gap of 2mm is left between the grid cavities as the support part of the sand mold (see figure 2 ).

[0030] The second step is to import the sand mold 3D entity into the computer of the 3D printing equipment.

[0031] The third step is to use 3D printing to complete the sand mold.

[0032] The fourth step is to bake and heat the sand mold (3 hours at 150°C). After the baking is complet...

Embodiment 2

[0036] The operation process and parameters of the spatial grid printing method of a 3D printing sand mold are as follows:

[0037] The size of the sand mold is 800mm×800mm, the height is 150mm, and the upper part is an arc surface structure of R=500mm, such as figure 1 shown.

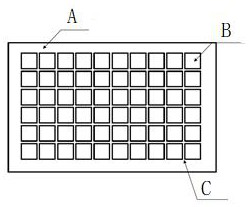

[0038] The first step is to leave a solid wall thickness of 80 mm at the sand mold boundary according to the size of the sand mold, and divide the rest of the space into a grid. Use a cube with a diameter of 6 mm to divide the inner space of the sand mold into each square space grid cavity, and each cube space A gap of 2mm is left between the grid cavities as the support part of the sand mold (see image 3 ).

[0039] The second step is to import the sand mold 3D entity into the computer of the 3D printing equipment.

[0040] The third step is to use 3D printing to complete the sand mold.

[0041] The fourth step is to bake and heat the sand mold (3 hours at 150°C). After the baking is completed, ...

Embodiment 3

[0045] The operation process and parameters of the spatial grid printing method of a 3D printing sand mold are as follows:

[0046] The size of the sand mold is 800mm×800mm, the height is 150mm, and the upper part is an arc surface structure of R=500mm, such as figure 1 shown.

[0047] The first step is to leave a solid wall thickness of 80 mm at the sand mold boundary according to the size of the sand mold, and divide the rest of the space into grids, using a cube grid whose circumscribed ball diameter decreases from 4 mm to 0.2 mm for each layer. Arranged radially from large to small, the internal space of the sand mold is divided into gradient grids of different sizes. (see Figure 4 ).

[0048] The second step is to import the sand mold 3D entity into the computer of the 3D printing equipment.

[0049] The third step is to use 3D printing to complete the sand mold.

[0050] The fourth step is to bake and heat the sand mold (3 hours at 150°C). After the baking is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com