A kind of preparation method of plywood

A plywood and veneer technology, applied in the direction of cleaning methods using liquids, cleaning methods using gas flow, cleaning methods and utensils, etc., can solve problems such as poor quality of plywood affecting normal use, weak pressure resistance of plywood, etc., to achieve temperature difference Precise, quality and life-enhancing effects, toughness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

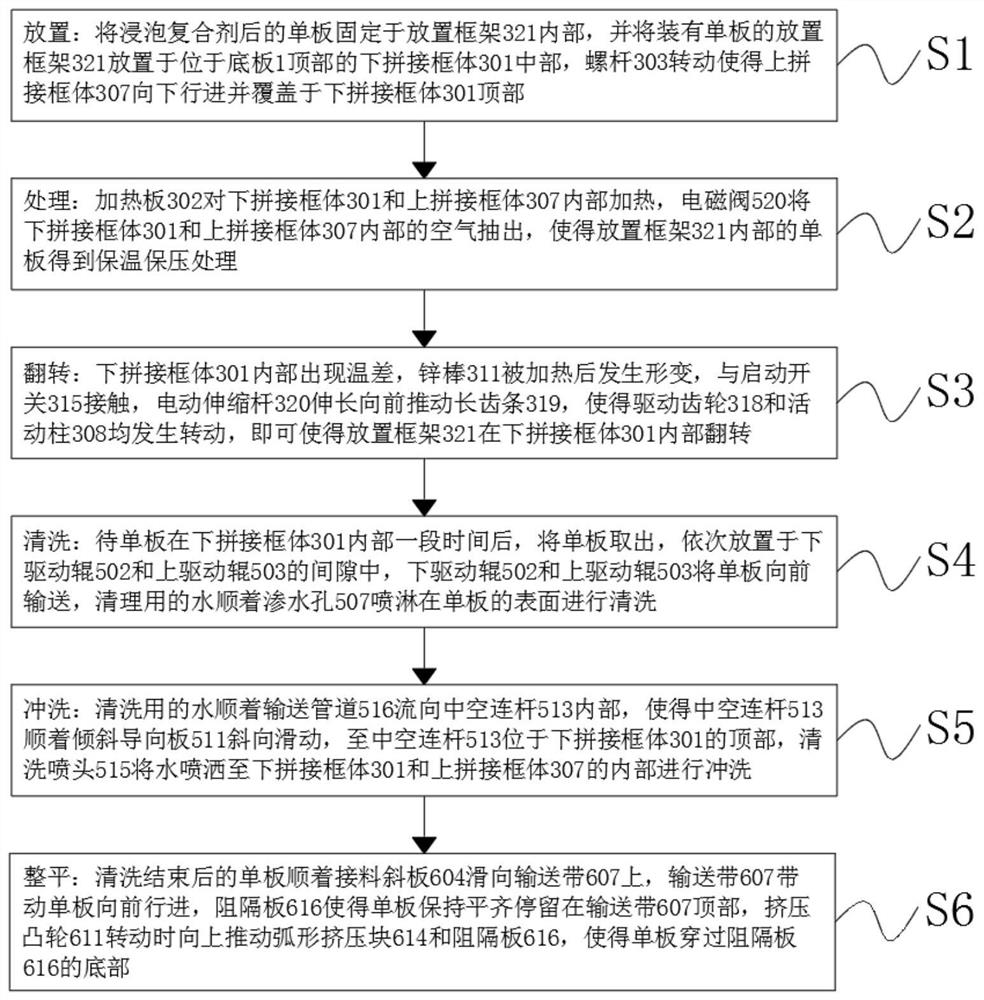

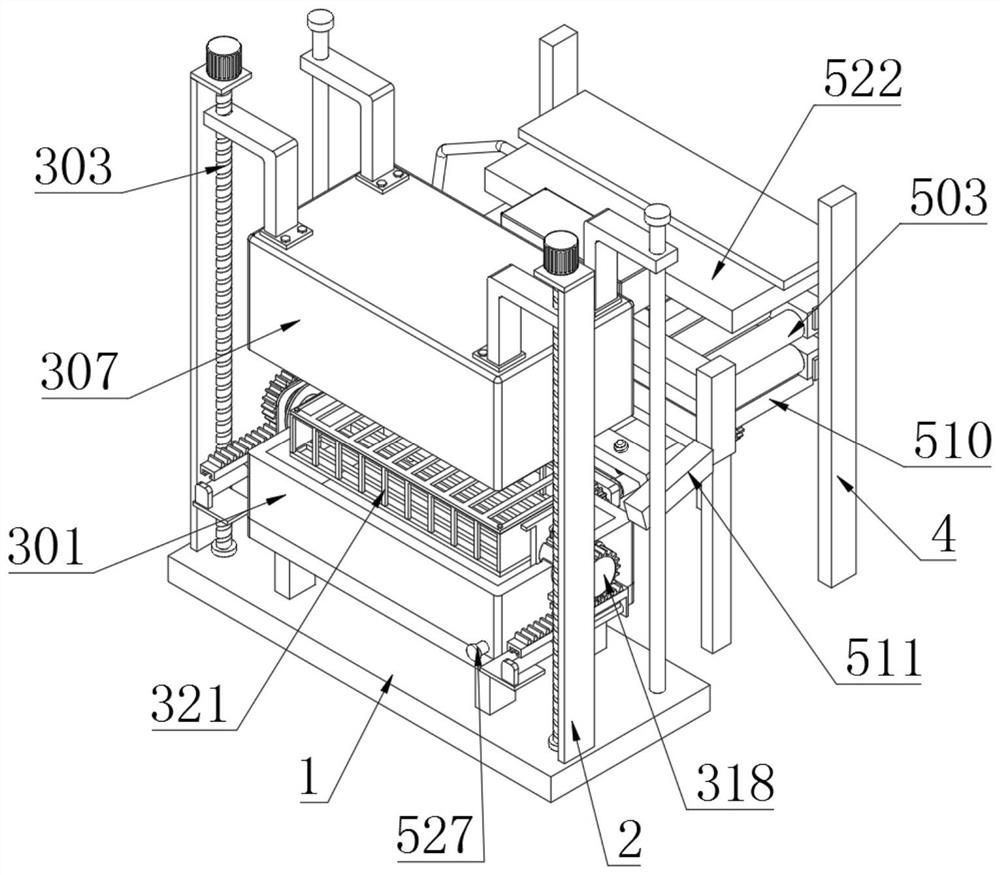

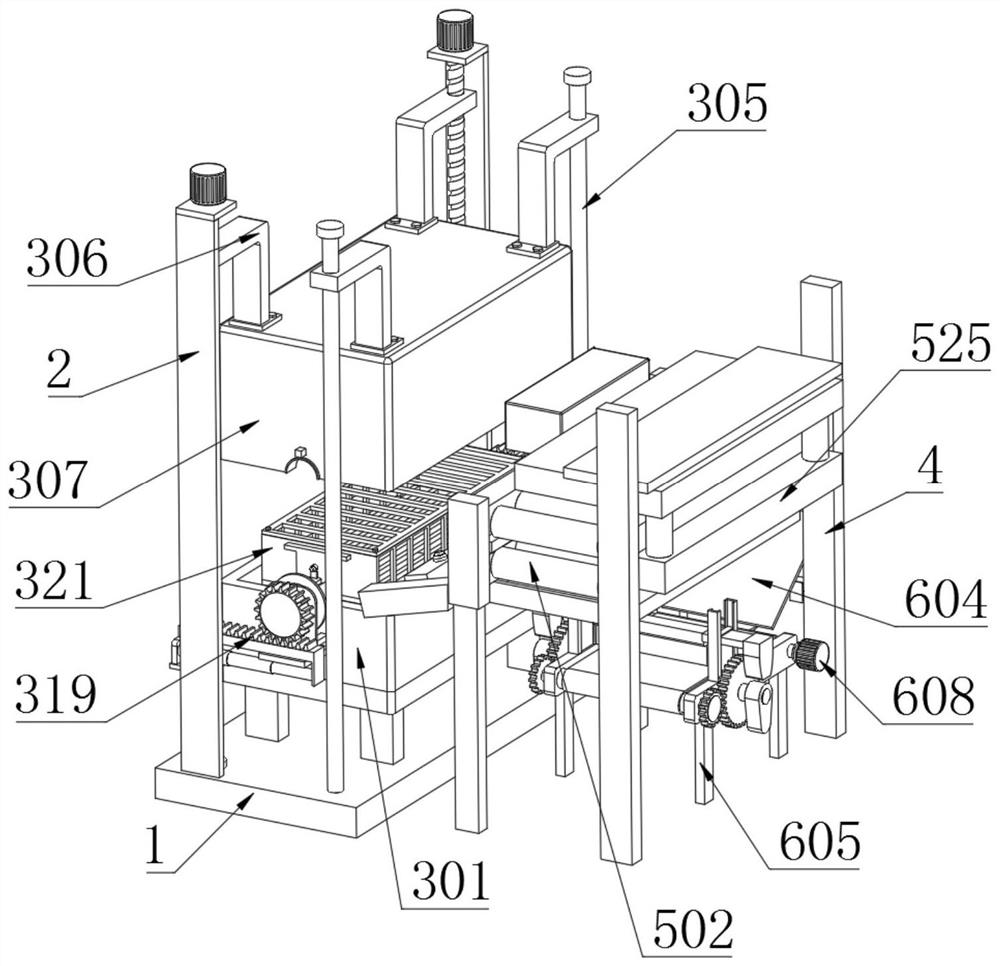

[0038] Example: Figure 1-11 As shown, the present invention provides a technical solution, a preparation method of a plywood, comprising the steps of:

[0039] S1: Place: The sheet after the soaking composite is fixed inside the placed frame 321, and placed the placed frame 321 equipped with a single plate in the lower splicing frame 301 in the top of the bottom plate 1, the screw 303 rotates so that the upper splicing frame The body 307 travels down and covered with the top of the lower splicing frame 301;

[0040] S2: Treatment: The heating plate 302 heats the lower splicing frame 301 and the upper splicing frame body 307, and the solenoid valve 520 extracts the air in the lower splicing frame 307 and the air inside the splicing frame 307, so that the single plate inside the frame 321 is placed. Get insulation preservation treatment;

[0041] S3: Turning: The temperature difference between the lower splicing frame 301 is formed, and the zinc rod 311 is formed after being heated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com