Reed straw manufacturing method and flock removing device thereof

A manufacturing method and technology of straws, applied in the direction of manufacturing tools, reed/straw treatment, wood processing equipment, etc., can solve the problems of inconvenient deflocculation of reeds, complicated production process, low qualified rate of reed straws, etc., and achieve a high degree of automation of deflocculation , Simplify the production process and facilitate the effect of removing flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

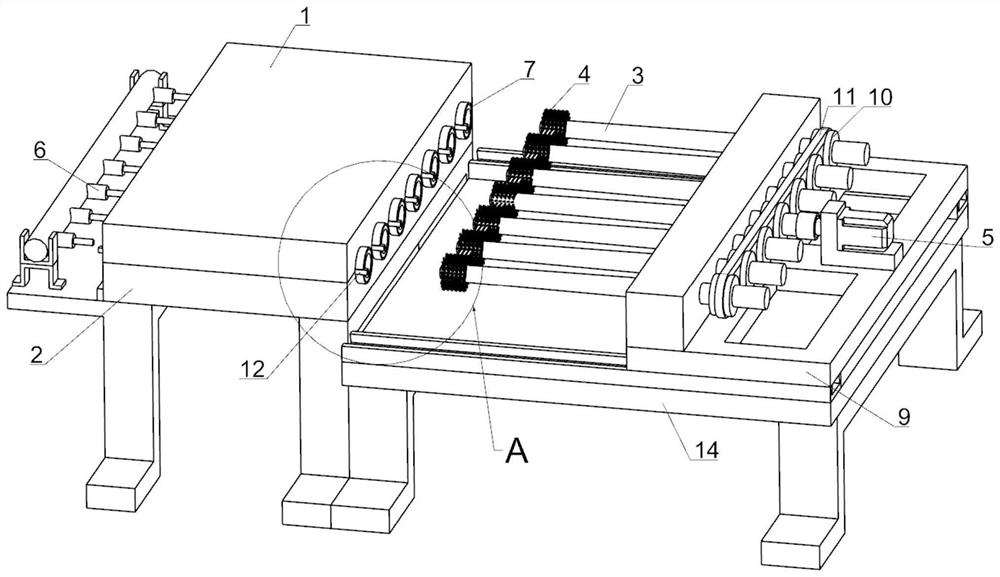

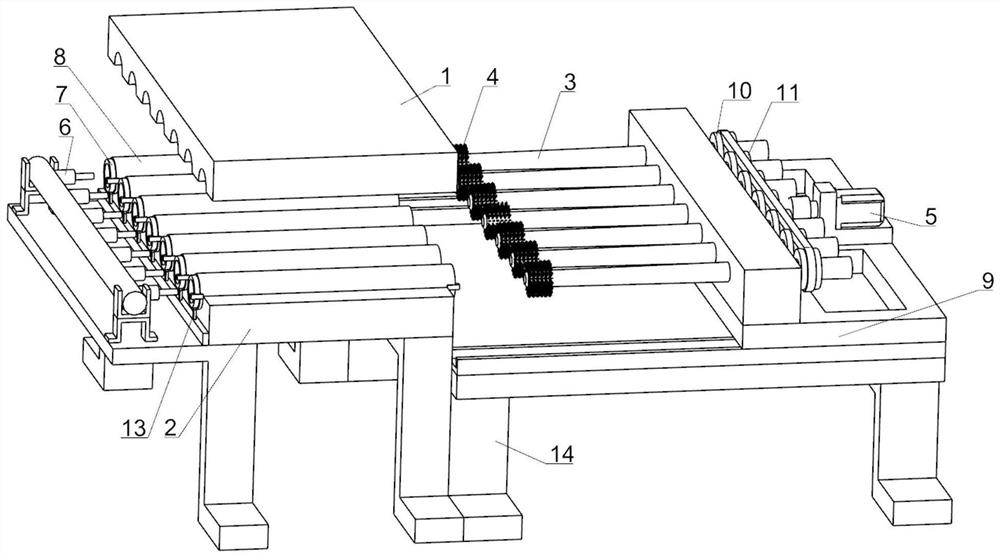

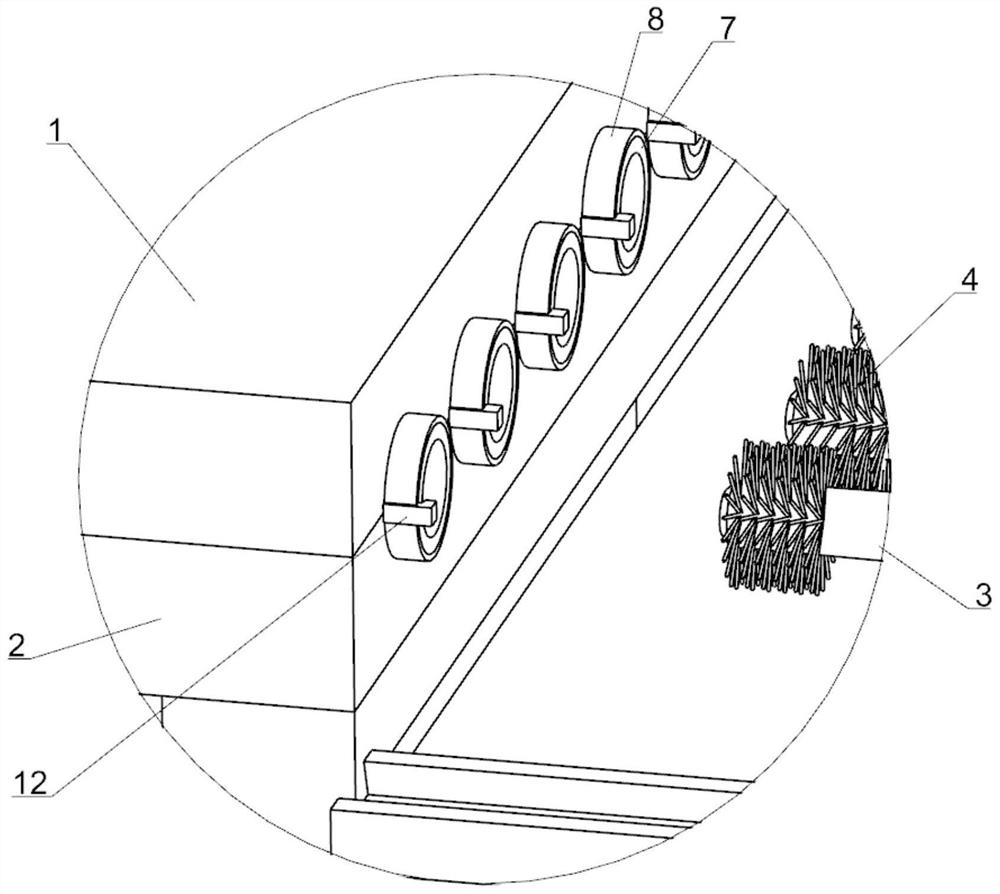

[0026] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] The embodiment of the present invention proposes a method for manufacturing a reed straw, which includes the following steps:

[0028] 1) Use artificial or conventional mechanical devices to select the reed rod 7 whose diameter meets the straw standard and the length between the two nodules reaches at least half of the straw standard length. The above-mentioned straw diameter and standard length depend on specific needs. ~5mm, the length is 15cm as an example;

[0029] 2) Use a cutting device to cut off the part between the two nodules of the reed rod 7 to ensure that the reed rod 7 and the leaf skin 8 are cut together, and the leaf skin 8 is wrapped outside the reed rod 7 to form an inner and outer two-layer tube, and the leaf skin One end of 8 cuts off a part more to expose the reed stem 7 of the inner layer and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com