Automatic cigarette carton packaging machine and multi-brand cigarette carton packaging machine

A technology for packaging machines and rods, which is applied in packaging and other directions, can solve the problems of high labor intensity, poor stability of side cigarettes, and large horizontal space occupation, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

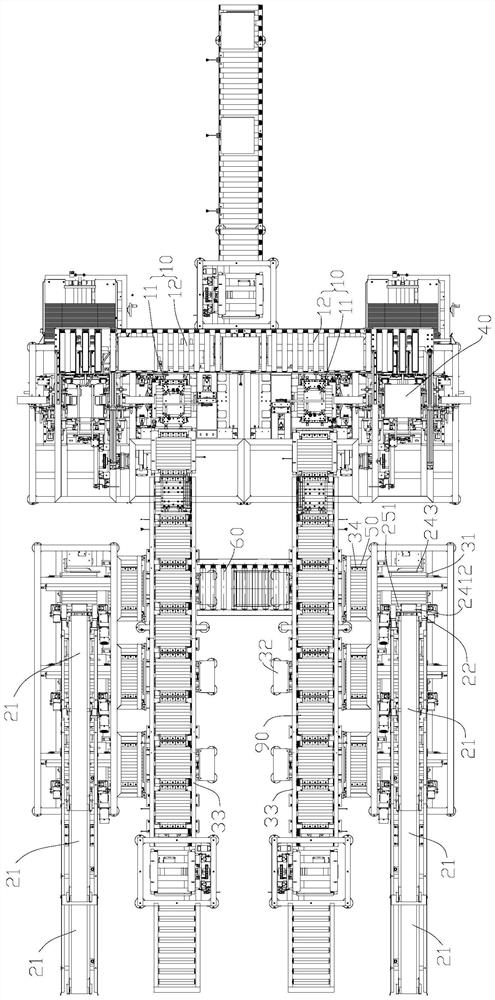

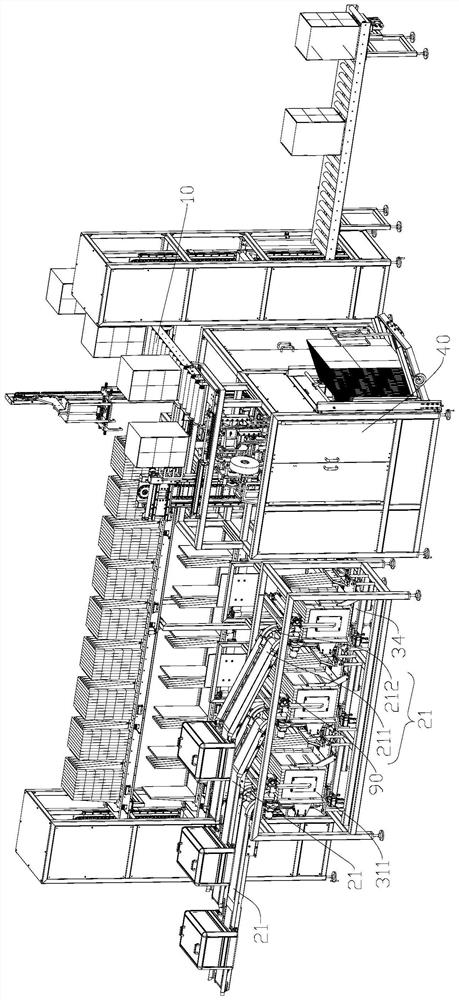

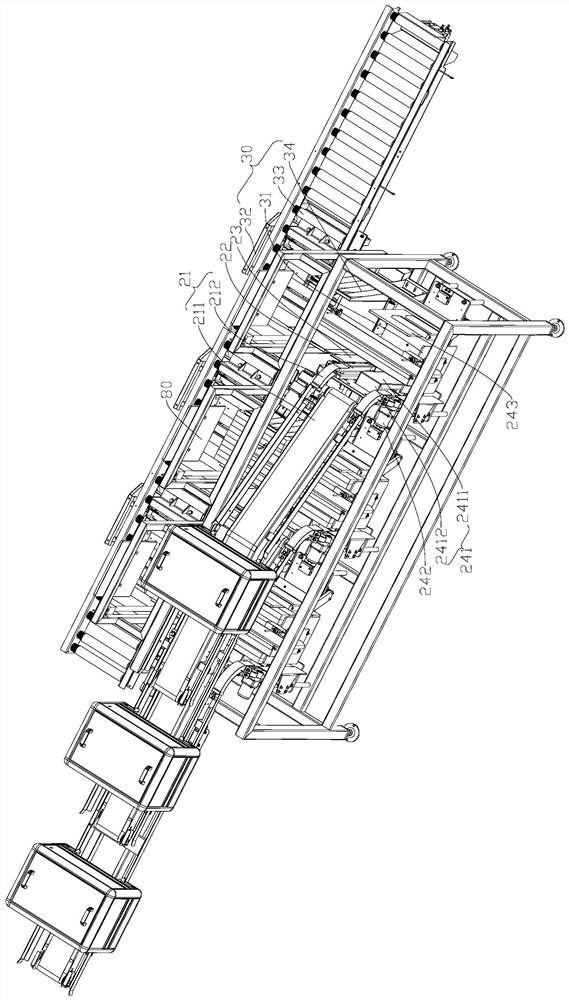

[0056] Such as Figure 1-10 As shown, an automatic cigarette packing machine includes a stacking device 20; the stacking device 20 includes an overturning conveying mechanism 21, a shroud 22, a blocking structure 23, a first pushing mechanism 24 and a stacking station 100; wherein,

[0057] The overturning conveying mechanism 21 is used to receive the horizontally placed cigarettes 90, and turn the horizontally placed cigarettes 90 to the side-standing state and output them one by one; The status output of the cigarette can control the height of the cigarette 90 standing sideways; here, the horizontally placed cigarette 90 can be turned over to the lateral side standing state by rotating 90° around the axis parallel to its length direction;

[0058] The coaming plate 22 is provided with a limiting groove, and the groove wall of the limiting groove is provided with a discharge opening connecting the limiting groove and the outside;

[0059] The blocking structure 23 is used to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap