Ice block carrying system of ice factory

A handling system and technology of ice cubes, applied in the directions of transportation and packaging, stacking of objects, destacking of objects, etc. problems, to reduce injuries and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

[0043] The invention relates to an ice cube handling system in an ice factory, which can realize the automatic handling of ice cubes in an ice factory, a storage warehouse, and out of a warehouse.

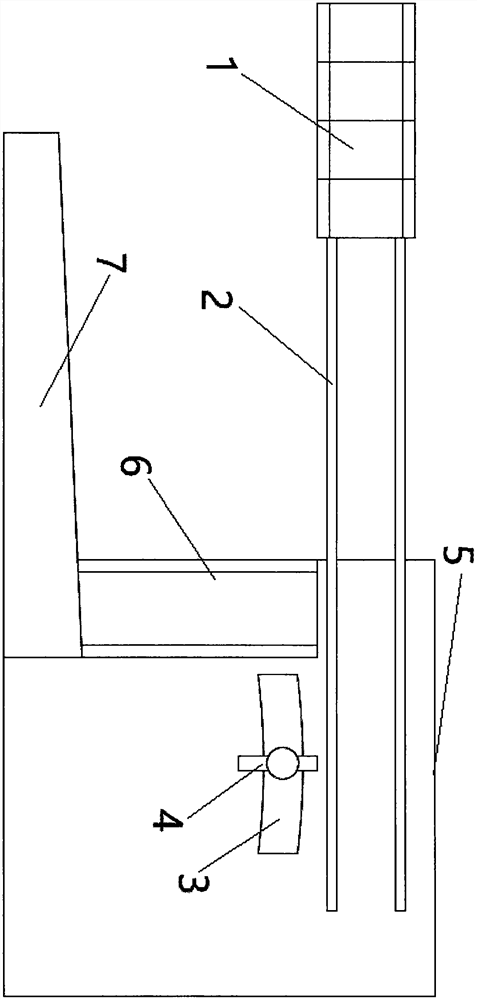

[0044]figure 1 A schematic diagram of the composition of the ice plant ice cube handling system of the present invention is shown. like figure 1 As shown, the ice cube handling system of the ice factory includes a plurality of ice cube modules 1 connected together. The ice cube module 1 is used to receive ice cubes produced from the ice making module and can move along the chain 2 into the ice cube storage 5 to transport the ice cubes to the ice cube storage 5 .

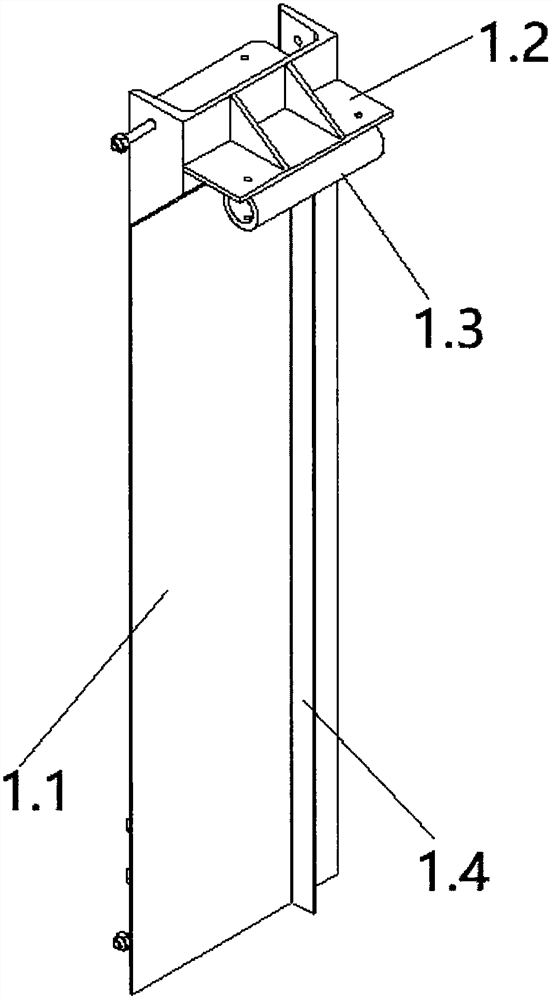

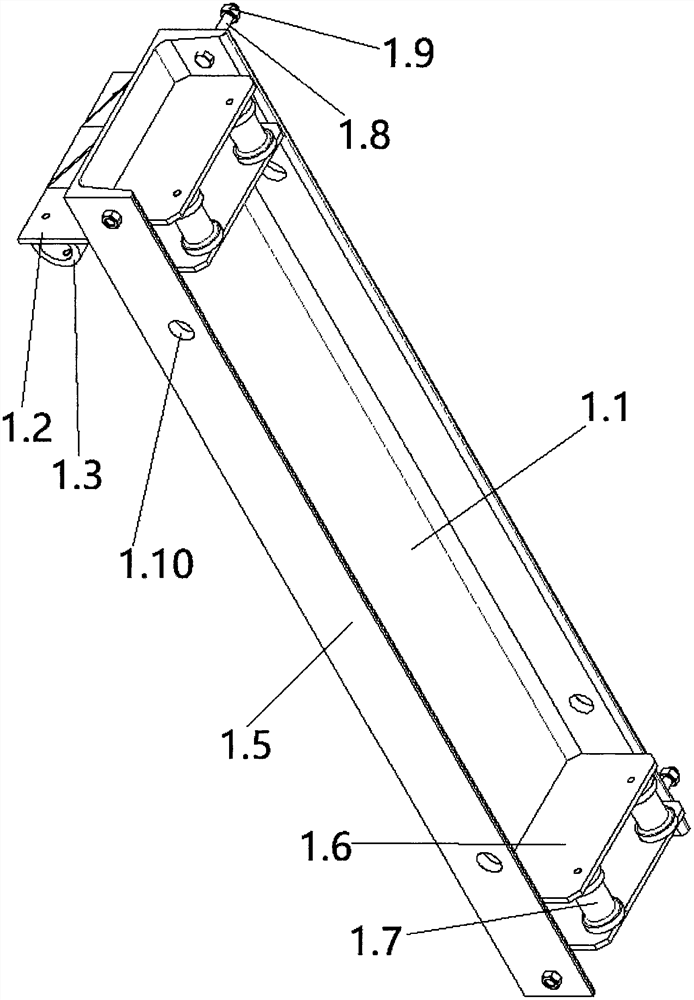

[0045] like figure 2 and 3 As shown, the ice cube module 1 includes a module base 1.1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com