Efficient solid-liquid separator

A solid-liquid separator, high-efficiency technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems that cannot meet the needs of high-turbidity water treatment and high-concentration suspended matter wastewater treatment, and achieve good treatment effects , Reasonable design and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

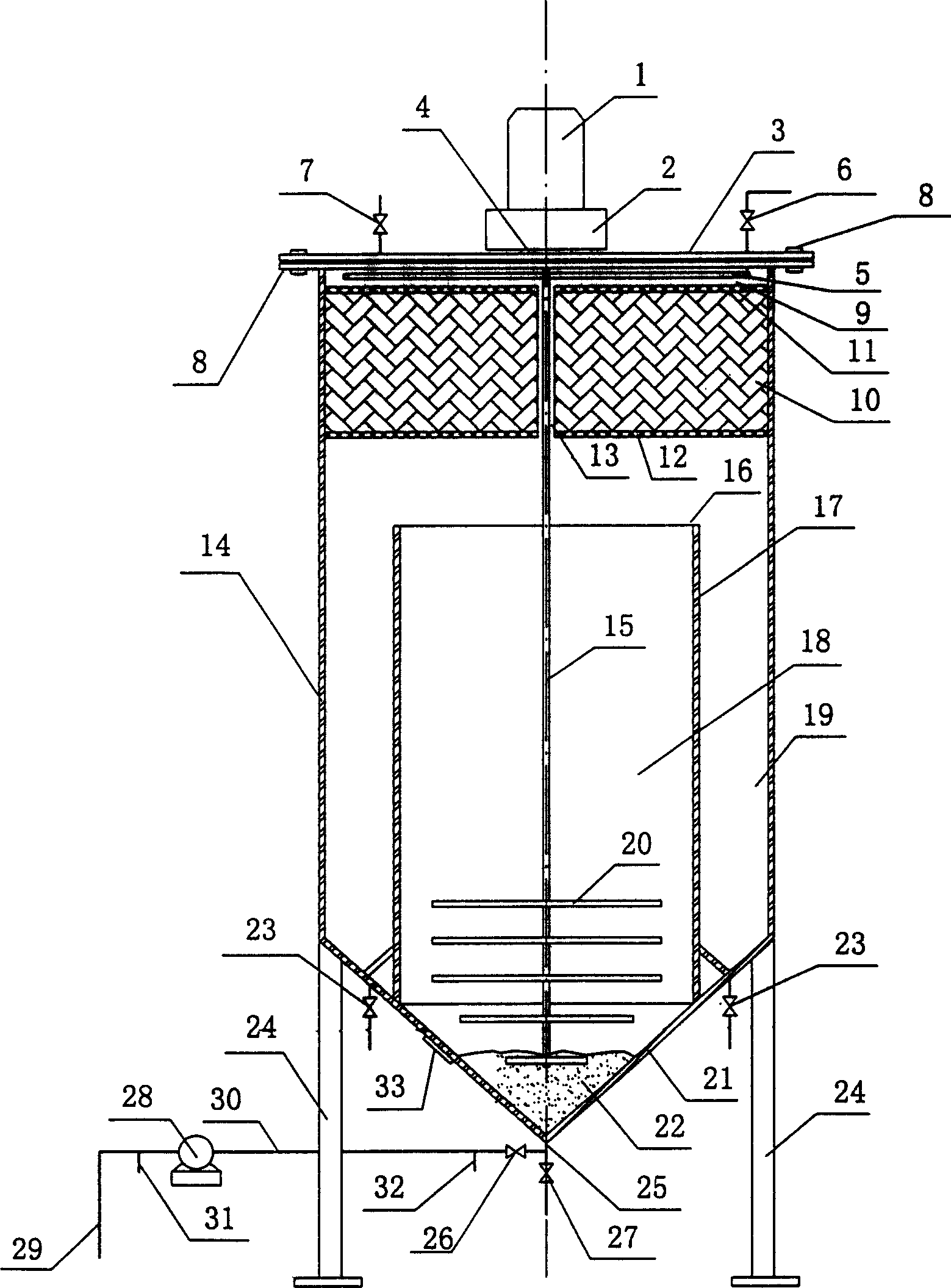

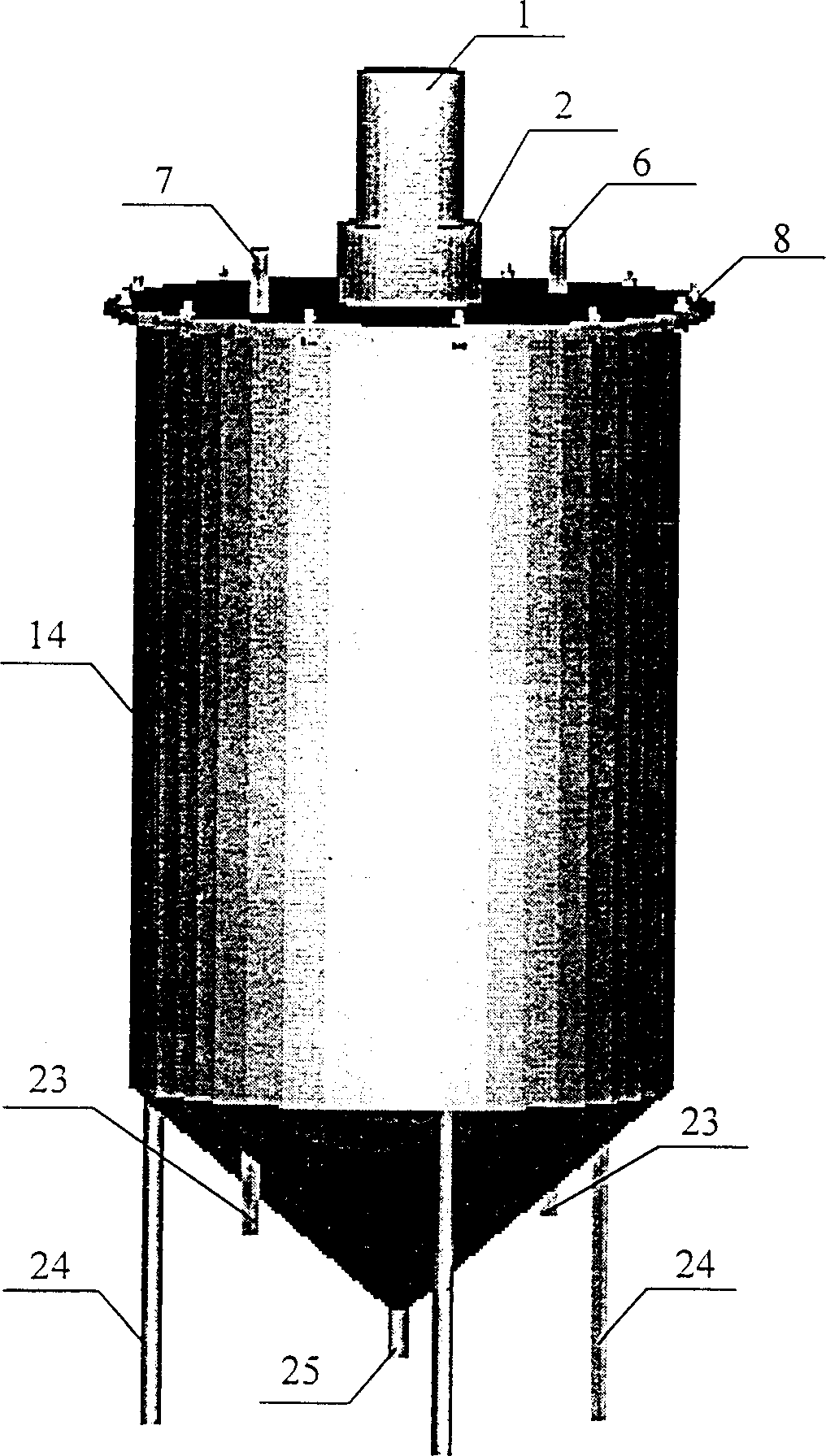

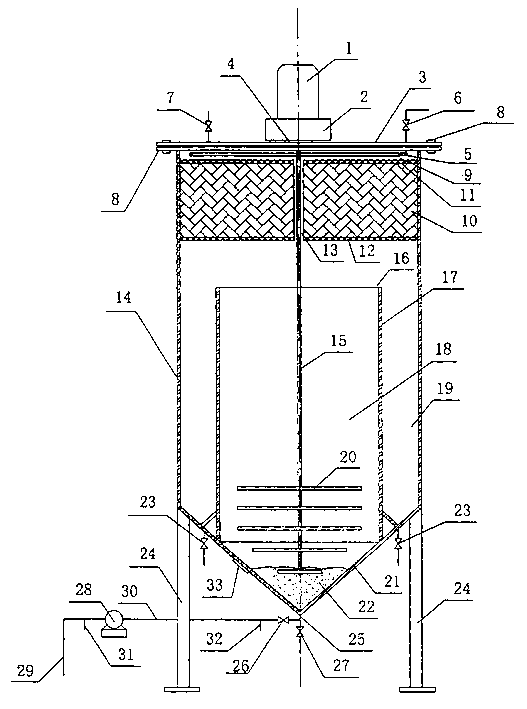

[0019] refer to figure 1 and figure 2 . The present invention mainly is made up of following three parts:

[0020] 1. The main device: the shape is a cylinder 14, the bottom is a cone 21, and the top is added with a top cover 3 to form a closed space. Inside the device, the inner cylinder 17 separates the lower space from the inside and outside, forming a central reaction zone 18 and an outer annular sludge concentration zone 19 . An annular weir 16 is formed on the top of the inner cylinder 17 to provide a passage for excess sludge to be discharged from the reaction zone 18 into the concentration zone 19 . On the upper part of the annular weir 16, the interior of the device is separated up and down by a circular large-hole mesh plate 12, and an independent Lagpe ring filling area 10 is formed on the upper part. The top of the Lagpe ring filling area 10 is separated from the water collection area 9 by a screen 11 again. The reaction area 18, the annular mud discharge wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com