Ship docking device and wharf

A ship and wharf technology, applied in the field of ship berthing devices and wharves, can solve the problems of long construction period and capital investment, reduce the utilization rate of berths, and damage the bollards when they are pulled down, and achieve a low labor intensity, simple structure, and easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

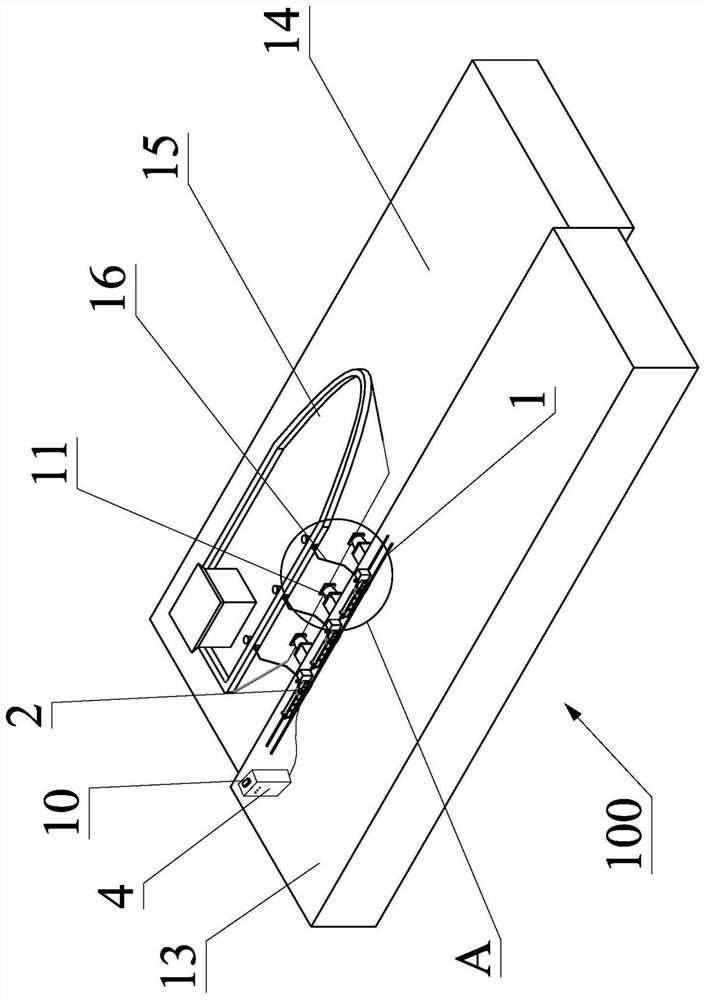

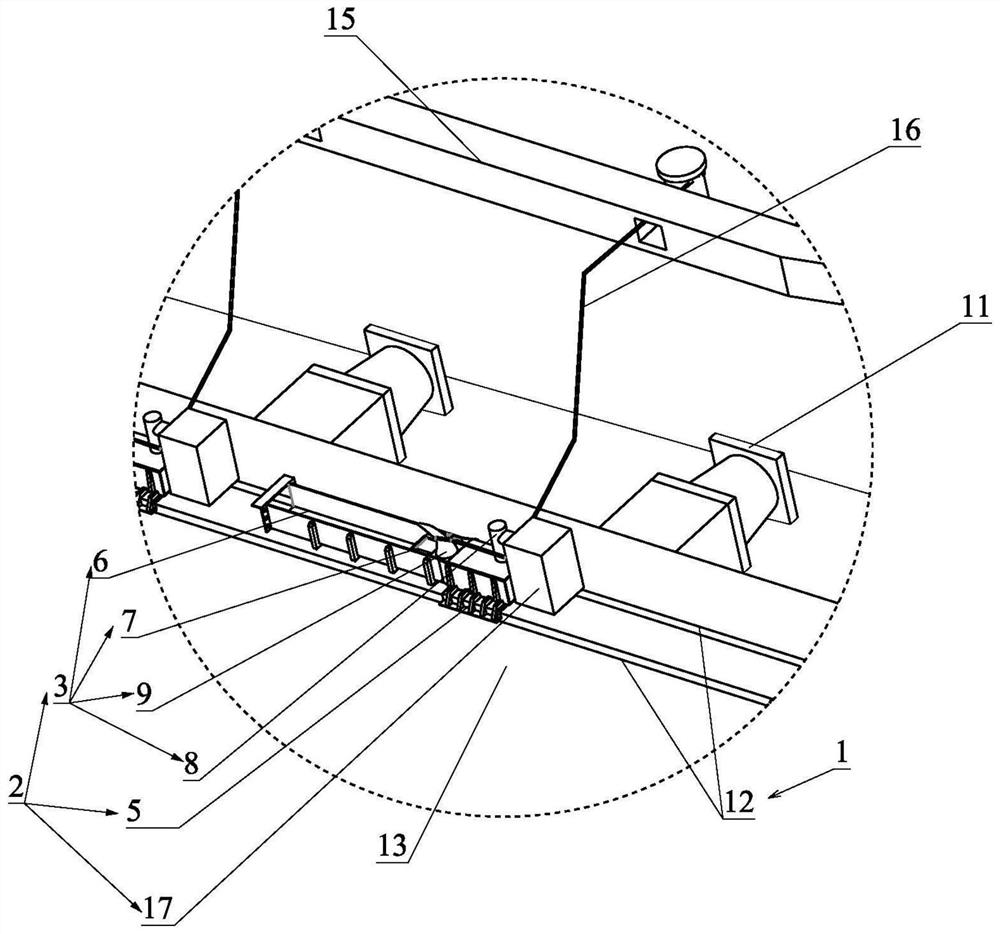

[0033] This embodiment provides a ship docking device 100, such as Figure 1~2As shown, in this embodiment, the ship docking device 100 includes a slide rail 1 and at least one slide assembly 2, the number of the slide assembly 2 can be determined according to the number of docked ships at the dock, and the slide rail 1 is used to be fixed on the dock shore 13, And extending along the direction of the front line of the pier, the sliding assembly 2 is slidingly connected with the sliding rail 1, and the sliding assembly 2 can be locked relative to the sliding rail 1. Used for fixed connection with the mooring rope 16; the mooring rope tightening assembly 3 can recover the mooring rope 16 and tighten it when the tension of the mooring rope 16 is less than the retracting force of the mooring rope tensioning assembly 3 on the mooring rope 16 when the pulling force of the mooring rope 16 is received by the ship 15; When the mooring rope 16 is pulled by the ship 15 and is greater th...

Embodiment 2

[0044] This embodiment provides a dock, such as Figure 1~2 As shown, in this embodiment, the wharf includes the ship berthing device 100 in the first embodiment, the slide rail 1 is used to extend along the front line of the wharf, and the slide assembly 2 can slide on the slide rail 1 and can be locked. The slide assembly 2 The position of the position can be adjusted arbitrarily, so that the sliding assembly 2 corresponds to the mooring rope 16 of the ship 15 docked in sequence in the dock, so as to avoid the excessive distance between two adjacent ships 15 and improve the utilization rate of the berth; The mooring rope tightening assembly 3 can retract the mooring rope 16, and when the mooring rope 16 is subjected to a pull force of the ship 15 that is less than the retracting force of the mooring rope tensioning assembly 3 to the mooring rope 16, the mooring rope 16 can recover the mooring rope 16 and Tightening, to improve the stability of the docking of the ship 15, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com