Mine rail transportation horizontal sump dredging structure and method

A technology of water tanks and mines, which is applied in the field of mine shaft engineering, can solve the problems of difficult maintenance, time-consuming and labor-consuming, and high maintenance costs in the later period, and achieve the effects of reducing maintenance costs and maintenance time, ensuring personnel safety, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

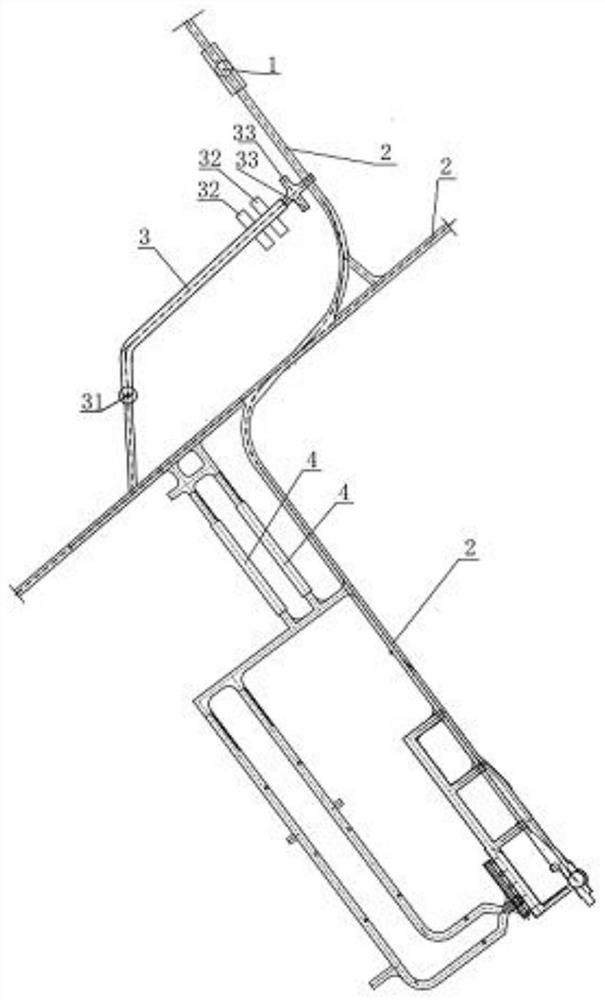

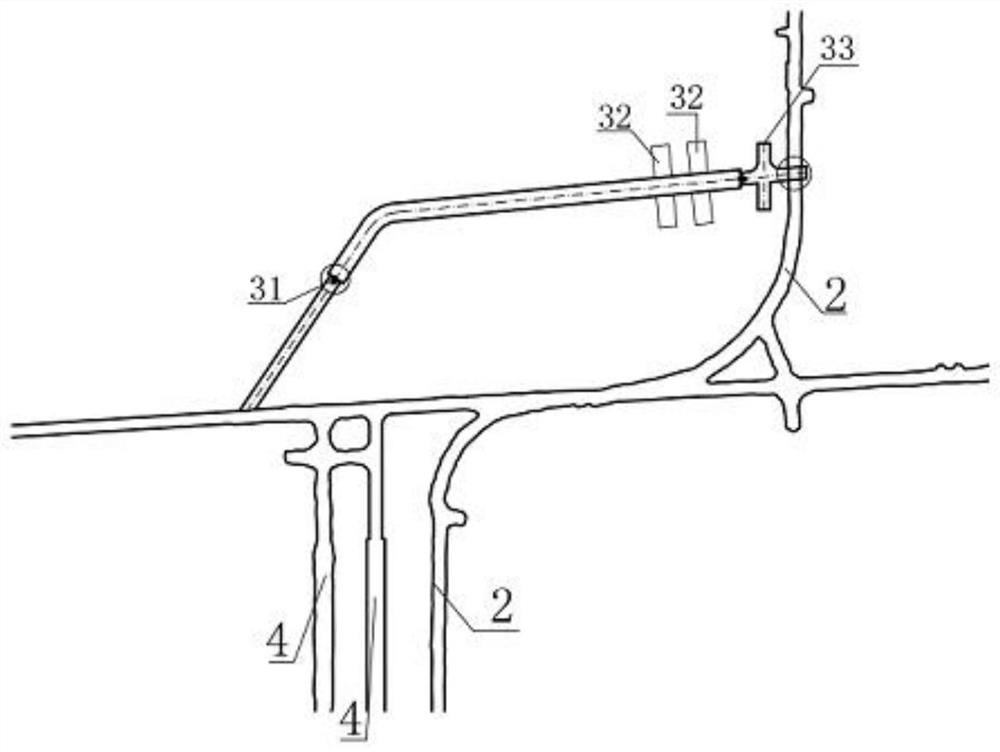

[0030] Below in conjunction with accompanying drawing, the present invention will be further described.

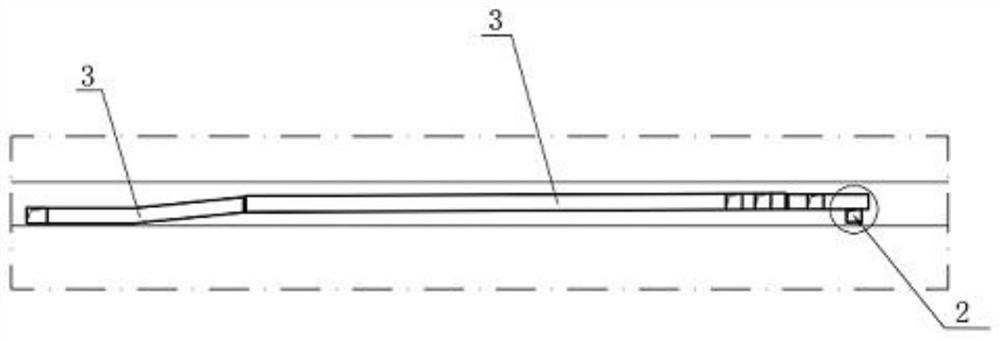

[0031] Such as figure 2 As shown, site selection is carried out in the adjacent track roadway 2, and a dredging chamber 3 with a gentle slope is designed to be excavated. One end of the dredging chamber 3 slope bottom opens near the water tank mouth, and the opening at the other end is Run through the railed roadway 2 so that it overlaps with the railed roadway 2, so that the sludge can be unloaded at the overlapped position with the railed roadway 2.

[0032] Such as figure 2 , 3 As shown, the dredging chamber 3 is provided with a water filter wall 31, a silt drain chamber 32 and a forklift turning chamber 33 successively from the place connected to the water tank mouth to the connection prescription with the track roadway, and the water filter wall 31 is used The silt is filtered, blocked in the dredging chamber 3, and the filtered water can be returned to flow into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com