Compressor buffer tank device

A technology of buffer tanks and compressors, which is applied in the direction of pump devices, mechanical equipment, machines/engines, etc. It can solve problems such as safety accidents, poor airflow pulsation suppression effect, and failure of pipe clamps in key connection parts of pipelines, so as to improve anti-vibration ability , Reduce the effect of air pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

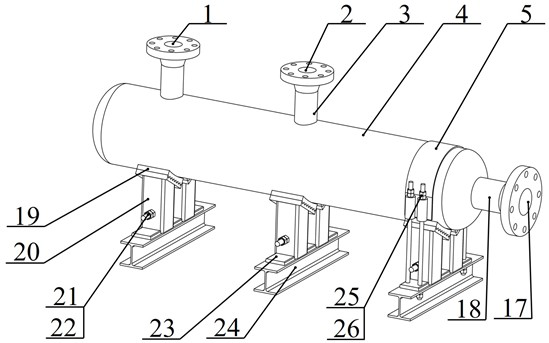

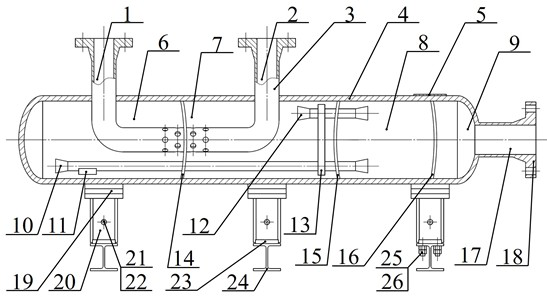

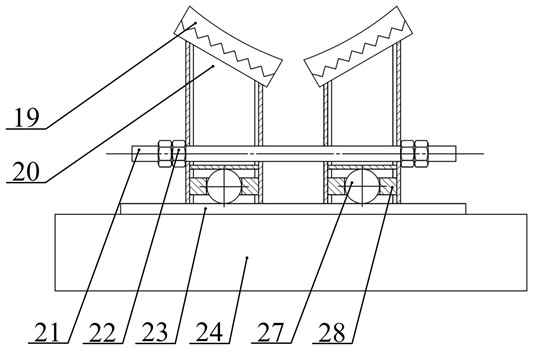

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Due to the suction and exhaust characteristics of reciprocating compressors, the airflow in the pipe is always pulsating, which cannot be eliminated from the source. The measure to reduce airflow pulsation is generally to add suppression devices to the subsequent pipeline. The present invention reduces the airflow pulsation through four stages, respectively through the intake pipe to reduce the airflow pulsation, the gas discharged from the intake pipe is fully buffered in the independent air chamber, and the pulsating gases of different exhaust ports are avoided from being directly superimposed on each other. Based on the Kunk tube The principle makes the pulsation amplitude of the pulsating gas cancel each other out, and then the fully mixed gas changes the waveform through the orifice plate to reduce the pulsation amplitude of the gas. During the process of reduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com