Dissolved oxygen calibration system

A calibration system and dissolved oxygen technology, applied in material inspection products, filtration separation, instruments, etc., can solve problems such as troublesome staff, time-consuming and laborious process, and calibration problems of ultra-low dissolved oxygen sensor by fluorescence method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

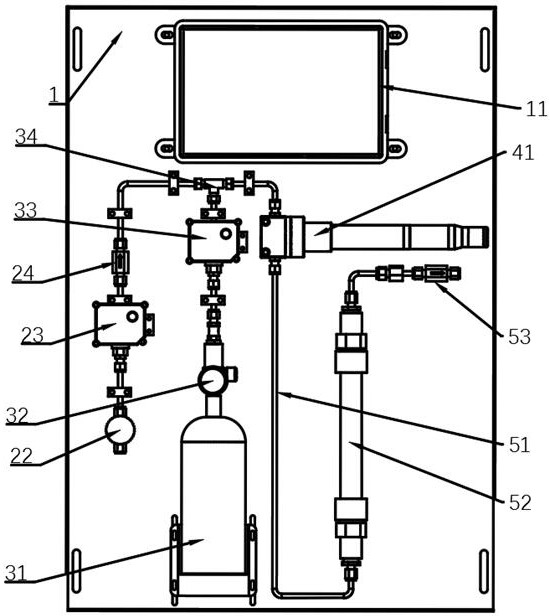

[0033] Example 1: See figure 1 , 3-13. The present invention provides a technical solution: a calibration system for dissolved oxygen, including a mounting plate 1, on which a water control component, an air control component, a detection component, and a drainage component are installed, and the water control component and the air control component are piped Communication, the gas control component is connected with the detection component pipeline, the detection component is connected with the drainage component pipeline, the water control component includes the handwheel valve 22, the first electric valve 23 and the check valve 24, the gas control component includes the air tank 31, the pressure reducing valve 32 and the second electric valve 33, the hand wheel valve 22 is connected to the first electric valve 23 with a pipeline, the other end of the first electric valve 23 is connected with the check valve 24, and the check valve 24 is connected to the second through a thr...

Embodiment 2

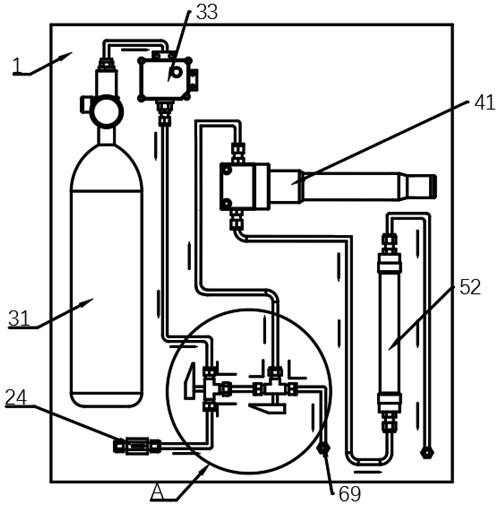

[0048] Example 2, such as figure 2 :

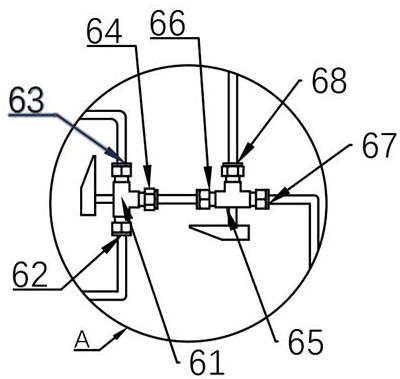

[0049]A first three-way valve 61 and a second three-way valve 65 are provided between the check valve 24, the second electric valve 33 and the dissolved oxygen sensor 41, and the first three-way valve 61 includes a first port 62, a second port 63 and a The third port 64, the second three-way valve 65 includes a fourth port 66, a fifth port 67 and a sixth port 68, the first port 62 is connected to the check valve 24 pipelines, and the second port 63 is connected to the second electric valve 33 pipelines Connection, the third interface 64 is connected to the fourth interface 66 pipeline, the fifth interface 67 is connected to the second drain pipe 69 pipeline, and the sixth interface 68 is connected to the inlet port 44 pipeline;

[0050] When the system is running normally, the first interface 62 communicates with the third interface 64, the fourth interface 66 communicates with the sixth interface 68, and the water sample to be measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com