Underground space crack monitoring device and method

A technology for underground space and monitoring devices, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as engineering hazards, achieve flexible layout, mature construction technology, and reliable design principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

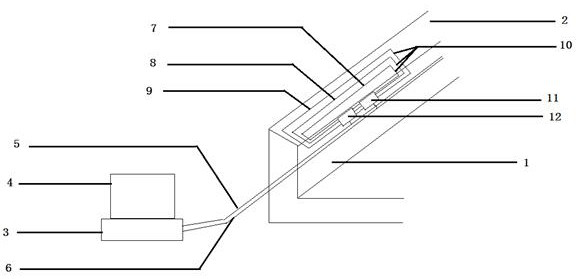

[0040] Please refer to figure 1 and figure 2 , this embodiment provides an underground space crack monitoring device, including:

[0041] (1) Material preparation of the conductive sensing strip: ordinary portland cement (density 3.10g / cm3); natural river sand for sand; 15mm PAN-based carbon fiber for carbon fiber with a density of 1.76g / cm3 and a diameter of 7μm; methyl cellulose And defoamer as a dispersant, fully disperse with carbon fiber in water, and then stir together with cement and sand; among them, the mixing amount of cement and sand is 1:1.

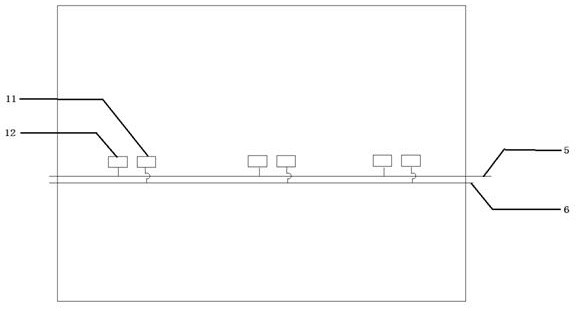

[0042] (2) Preparation of conductive sensing strips: Arrange the uniformly stirred intelligent sensing materials in lengths of 3m, 2.9m, and 2.8m, and arrange strips with a width of 1cm from the outside to the inside (with a spacing of 0.1m), and fill them in the underground space Among the construction joints and deformation joints reserved for the structure, the numbers are the conductive sensing strip 7 numbered 1, the c...

Embodiment approach

[0047] (1) The computer control terminal 4 issues a command to supply power to the DC power supply 12 .

[0048](2) The DC resistance test module 11 measures the resistance value of the conductive sensing strip 7 numbered 1, the conductive sensing strip 8 numbered 2, and the conductive sensing strip 9 numbered 3. If the conductive sensing strip 7 numbered 1, the conductive sensing strip 8 numbered 2, and the conductive sensing strip 9 numbered 3 are structurally intact and their resistance value is close to 0; if the conductive sensing strip 7 numbered 1 and the conductive sensing strip 9 numbered 2 The resistance value of one or more of the conductive sensing strip 8 and the conductive sensing strip 9 numbered 3 increases, indicating that the structure where the conductive sensing strip is located is cracked or there is a possibility of crack development. In order to further improve the monitoring accuracy, it is necessary to set the resistance threshold in advance. When the ...

Embodiment 2

[0053] In the underground space crack monitoring device provided in this embodiment, only one conductive sensing strip is laid in the reserved seam of the same section, and a conductive sensing strip circuit is constructed to monitor the resistance of the conductive sensing strip. The number of conductive sensing strips of the present invention is not fixed, and can be set according to needs.

[0054] In order to improve the installation speed of the device, the air-dried conductive sensing strip can be prepared in advance, and the bottom of the conductive sensing strip and the reserved seam can be fixed together with cement as an adhesive, so that the conductive sensing strip can be quickly installed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com