Cigarette filter tip feeding mechanism

A filter tip and cigarette technology, which is applied in the fields of tobacco, cigarette manufacturing, and application, can solve problems such as low conveying efficiency, clogging of cigarette filter tips, clogging of conveying equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

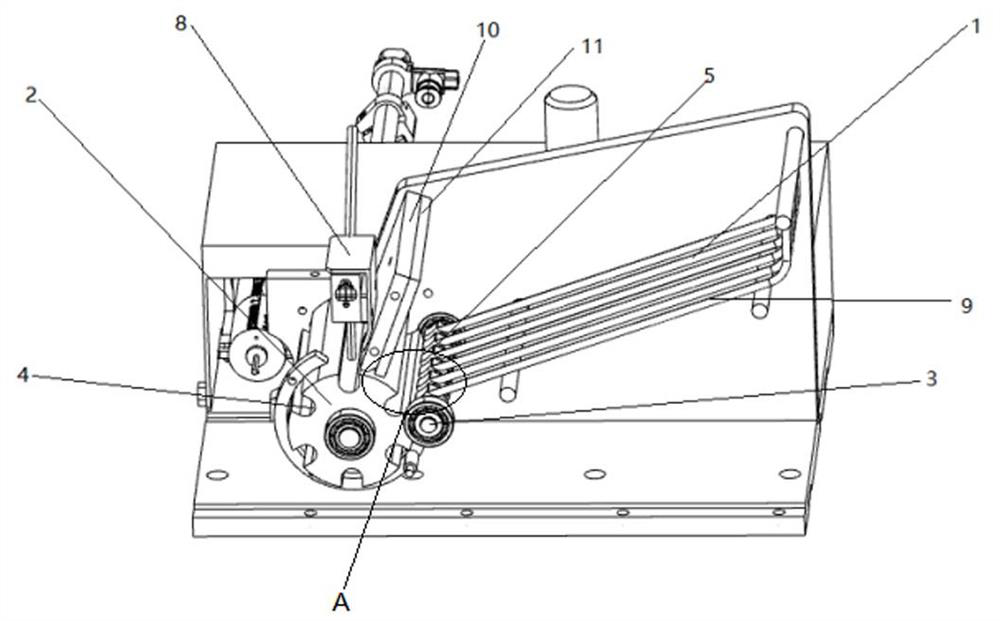

[0033] Please refer to figure 1 , 2 and 3, a cigarette filter feeding mechanism, comprising, a feeding module, which includes a feeding ramp 1 arranged obliquely, used for feeding cigarette filters;

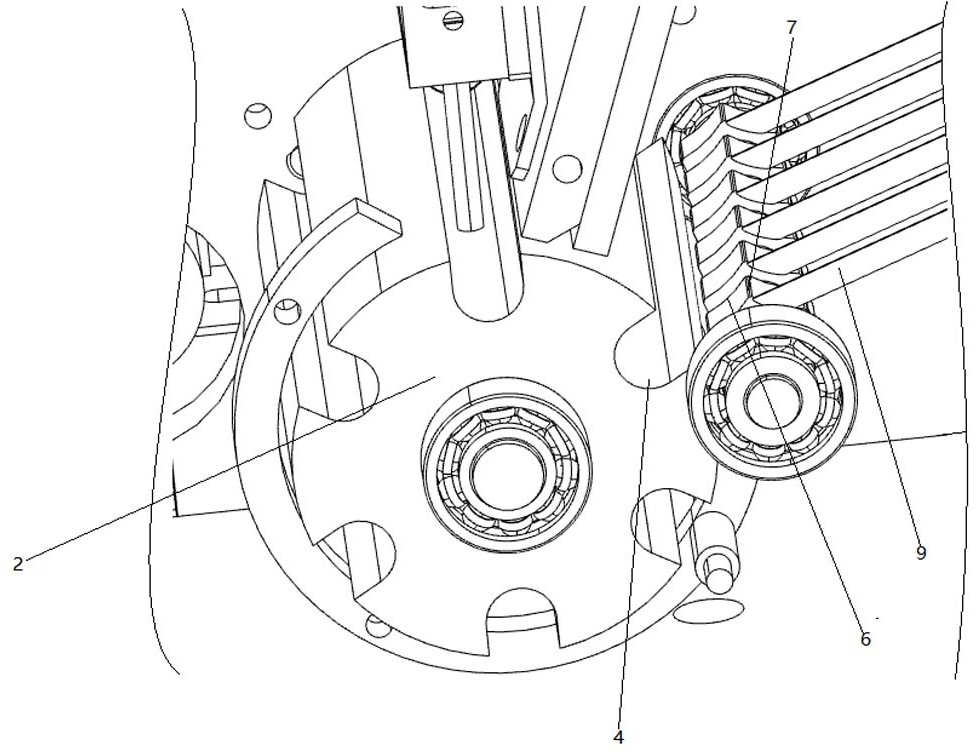

[0034] The feeding roller 2, the circumference of the feeding roller 2 is provided with several U-shaped grooves 4; the U-shaped grooves 4 are used for the transportation of cigarette filters;

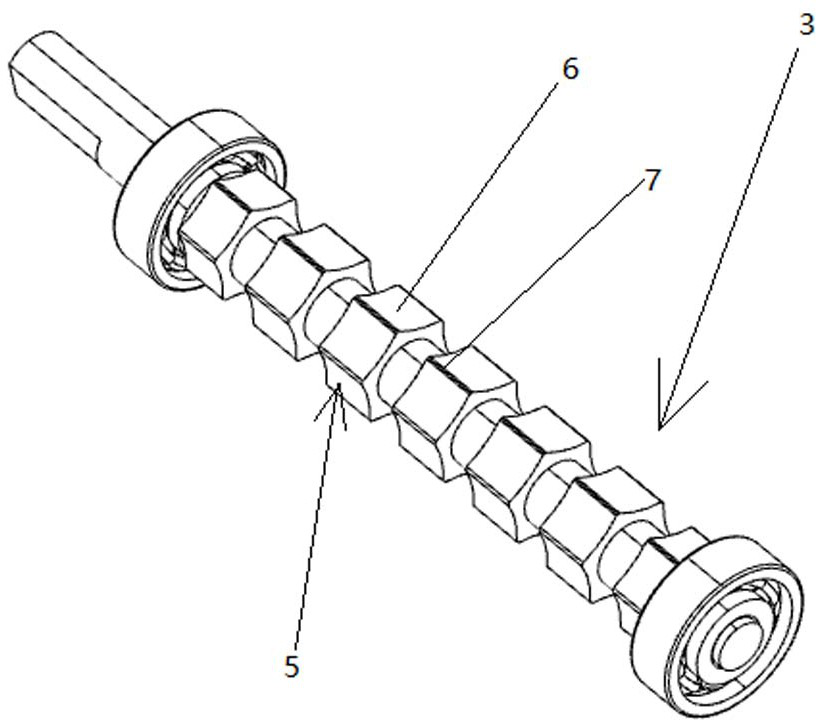

[0035] The auxiliary material roller 3 is located between the upper material roller 2 and the unloading module, and is connected with the bottom of the unloading module; There are several arc-shaped grooves 6 in the circumferential direction; the auxiliary wheel 5 is used to prevent the cigarette filter from being stuck out of the feeding roller 2;

[0036] A driving mechanism, used to drive the feeding roller 2 and the auxiliary feeding roller 3 to rotate intermittently;

[0037] The photoelectric detection device 8 is arranged above the feeding roller 2 and is used to detect whether ...

Embodiment 2

[0046] The following introduces the use steps of the cigarette filter feeding mechanism in this embodiment, including the following steps:

[0047] (1) The cigarette filter tip is rolled from the top of the feeding ramp 1 to the bottom, and deposited along the feeding ramp 1 or at the bottom of the feeding ramp 1;

[0048] (2) The feeding roller 2 and the auxiliary material roller 3 rotate synchronously, and the auxiliary material roller 3 drives the deposited cigarette filter into the U-shaped groove 4;

[0049] (3) The scraper 11 scrapes off excess cigarette filters, and the guide plate 10 guides the cigarette filters stuck between the scraper 11 and the material roller into the U-shaped groove 4;

[0050] (4) The U-shaped groove 4 drives the cigarette filter tip to move counterclockwise. When the feeding roller 2 drives the U-shaped groove 4 equipped with the cigarette filter tip to move to the lower left, under the action of gravity, the cigarette filter tip realizes self-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com