Stamping die with discharging function for automobile precision part

A technology for precision parts and stamping dies, which is applied in the field of stamping dies for automobile precision parts, can solve the problems of time-consuming and laborious, manual discharge, etc., to achieve stamping protection, facilitate automatic discharge, and reduce labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

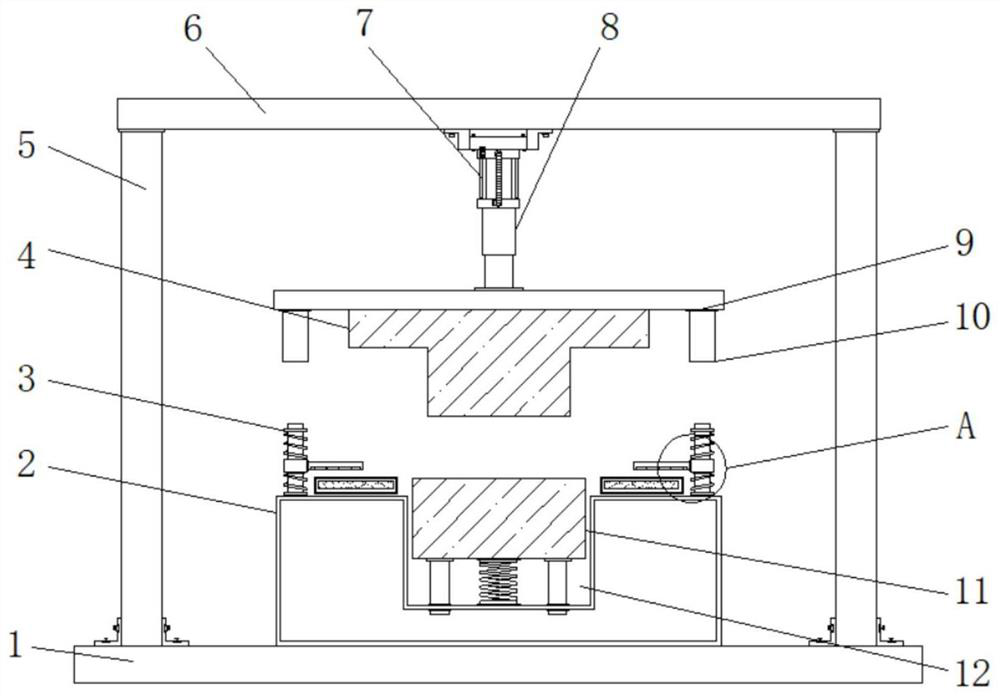

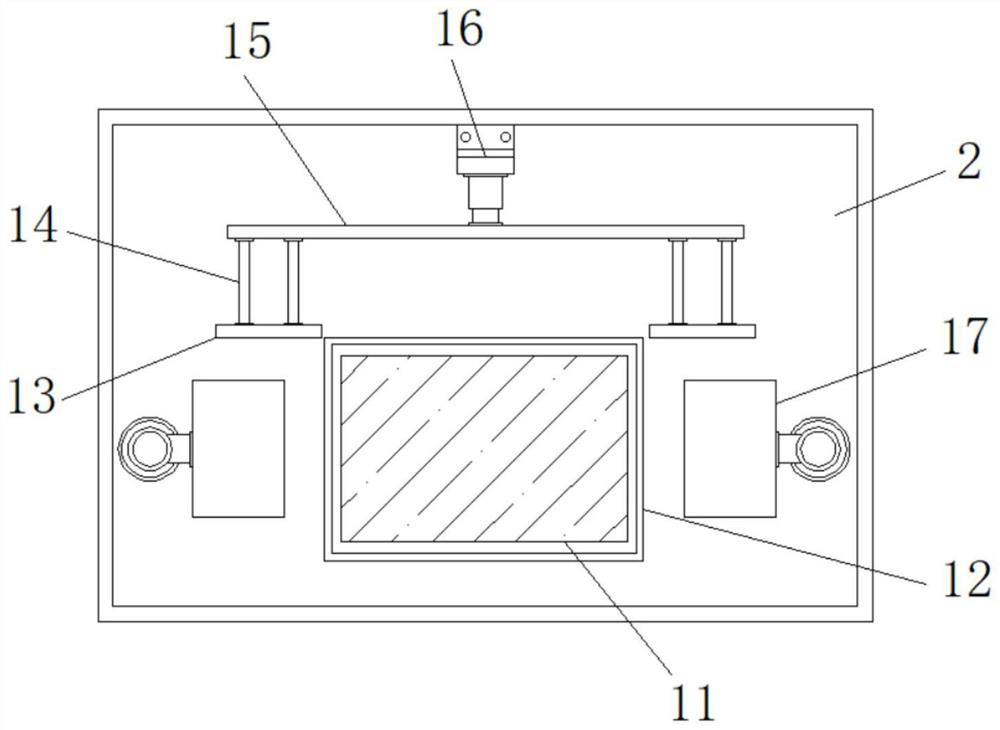

[0021] Example 1: See Figure 1-4 , a stamping die for automotive precision parts with a discharging function, comprising a base 1, two sets of columns 5 are fixedly welded on both sides of the top of the base 1, a horizontal plate 6 is fixedly welded on the top of the column 5, and the bottom of the horizontal plate 6 end is fixedly connected with a cylinder 7, the output end of the cylinder 7 is fixedly connected with a telescopic rod 8, the top of the base 1 is fixedly connected with a workbench 2, the bottom end of the telescopic rod 8 is fixedly connected with a fixed plate 9, and the bottom end of the fixed plate 9 is fixed The upper mold 4 is connected, the two sides of the top of the workbench 2 are fixedly connected with the limit column 3, the inside of the workbench 2 is provided with a groove 12, the inside of the groove 12 is placed with a lower mold 11, and one end of the top of the workbench 2 is set There is a push plate 13;

[0022] see Figure 1-4 , a stamp...

Embodiment 2

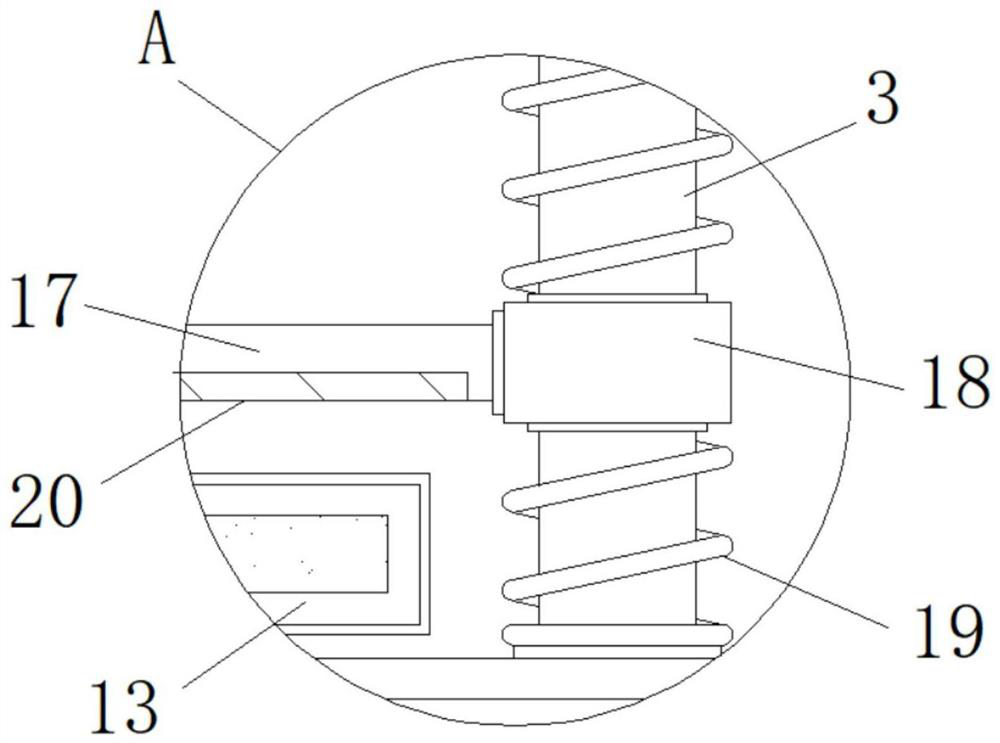

[0024] Embodiment 2: the limit spring 19 is socketed on the outside of the limit post 3, the slide sleeve 18 is connected to the outside move of the limit post 3, one side of the slide cover 18 is fixedly connected to the limit plate 17, and the limit plate 17 The bottom end is fixedly connected with a rubber pad 20, and the two sides of the bottom end of the fixed plate 9 are fixedly connected with two sets of sleeves 10;

[0025] The limit post 3 is provided with two groups, and the sliding sleeve 18 outside the limit post 3 is arranged between the limit springs 19, and the limit spring 19 can drive the slide sleeve 18 to move together during the movement;

[0026] Specifically, such as figure 1 and image 3 As shown, when an automobile part is placed above the lower mold 11, the middle of the part will be stamped and bent. During the stamping process, the bushings 10 on both sides of the upper mold 4 are set on the outside of the stopper column 3 and pressed down to move t...

Embodiment 3

[0027] Embodiment 3: two sets of limit rods 21 are fixedly connected to both sides of the bottom end of the lower mold 11, a return spring 22 is fixedly connected between the lower mold 11 and the groove 12, and two sets of through holes 23 run through the inside of the groove 12. The outer dimension of the lower mold 11 is smaller than the inner dimension of the groove 12, and the limit rod 21 at the bottom of the lower mold 11 is embedded in the inside of the through hole 23;

[0028] Specifically, such as figure 1 and Figure 4 As shown, in the process of stamping the lower mold 11 by the upper die 4, firstly, the casing 10 first contacts the limit post 3 and exerts pressure on the limit spring 19 outside the limit post 3 to cause the spring to retract. When the spring retracts, it will Provide back impact force and buffer force, and then during the downward movement of the lower mold 11, the limit rod 21 at the bottom of the lower mold 11 is inserted into the through hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com