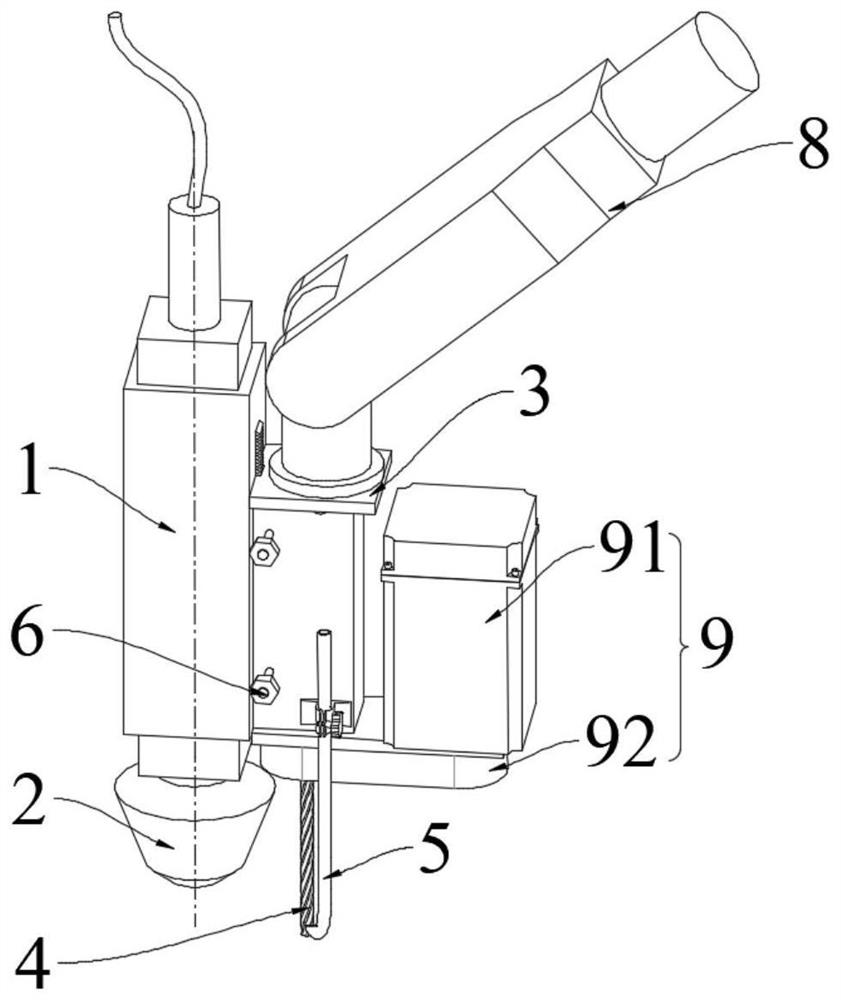

Mechanical subtractive and laser additive synchronous machining device and method

A laser additive and synchronous processing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as excessive debris and quality impact of additive manufacturing layers, so as to save processing costs, reduce damage, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

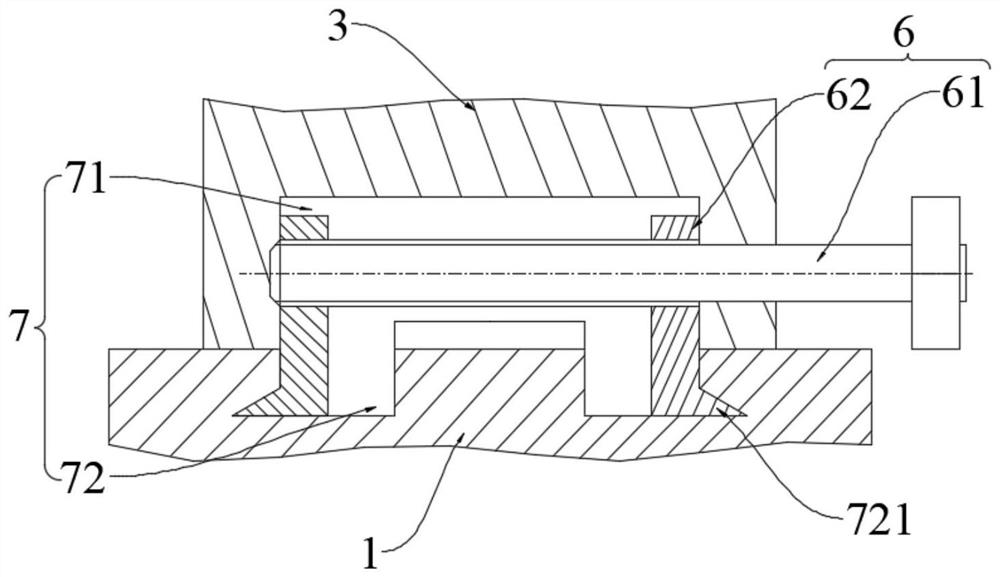

Method used

Image

Examples

Embodiment 1

[0089] This embodiment provides a processing method based on a synchronous processing device of mechanical subtractive material and laser additive material, on the surface of the workpiece to be processed to additively manufacture a multi-layer metal deposition structure, which specifically includes the following steps:

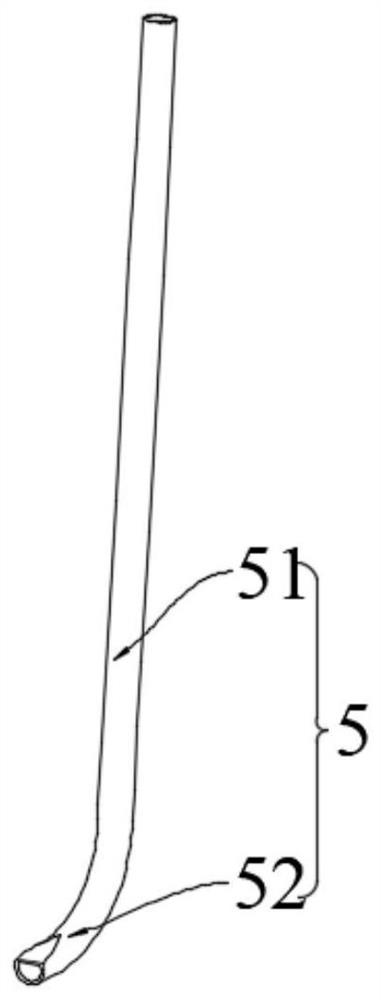

[0090] 1.1. Set the optimized milling tool 4 processing parameters: milling tool 4 feed speed V 1 , Milling tool 4 speed V 2 , Milling depth H 1 , the height H between the bottom of the suction pipe 5 and the surface of the workpiece to be processed 2 ;Laser parameters: the distance H between the laser focus O and the surface of the workpiece to be processed 3 , laser power, laser moving speed, and the laser moving speed and the feed speed V of the milling tool 4 1 Equal; powder feeding parameters: powder feeding rate and powder particle size, and input the optimized processing parameters into the control program, and determine the chemical composition of ...

Embodiment 2

[0095]This embodiment provides a processing method based on a synchronous processing device of mechanical subtractive material and laser additive material, which is used to additively manufacture a gradient structure metal deposition structure on the surface of the workpiece to be processed. The processing method provided in this embodiment is the same as that in Example 1. The method is the same, the difference is that the last step adopts the following method:

[0096] After the first layer of additive manufacturing is completed, the mechanical subtractive material and laser additive synchronous processing device are lifted by the manipulator 8 to an average height of the deposited layer, and steps 1.1 to 1.3 are repeated, that is, the previous metal additive manufacturing After that, it is necessary to reset the chemical composition of the powder, and adjust the milling tool 4 processing parameters, laser parameters and powder feeding parameters in time until the predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com