High-safety fuel cell electrolytic bath system and working method thereof

A fuel cell, high-safety technology, applied in the field of electrolysis cells, can solve problems such as hidden safety hazards, inconvenient use, and low efficiency of SOEC systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

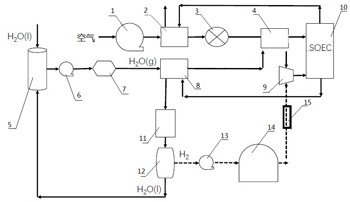

[0035]as attached figure 2 As shown, a high-safety fuel cell electrolyzer system includes: fan 1, air heat exchanger 2, electric heater 3, air-gas heat exchanger 4, water tank 5, water pump 6, steam generator 7, gas Heat exchanger 8, mixer 9, SOEC stack 10, condenser 11, water-gas separator 12, booster pump 13, high-pressure gas cylinder 14, flow meter 15.

[0036] The blower 1, the air heat exchanger 2, the electric heater 3, and the air-gas heat exchanger 4 are connected in sequence to form a supply flow path on the cathode side. The fan 1 is used to compress the air and send it to the air heat exchanger 2; the air heat exchanger 2 is used to send the air sent by the fan 1 and the high-temperature cathode tail gas discharged from the SOEC stack 10 heat exchange; the electric heater 3 is used to heat the air; the air-gas heat exchanger 4 is used to exchange heat between the high-temperature air heated by the electric heater 3 and the water vapor on the anode side. The abov...

no. 2 Embodiment approach

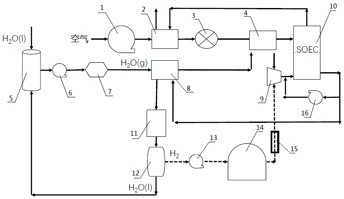

[0044] as attached image 3 As shown, a high-safety fuel cell electrolyzer system includes: fan 1, air heat exchanger 2, electric heater 3, air-gas heat exchanger 4, water tank 5, water pump 6, steam generator 7, gas Heat exchanger 8, mixer 9, SOEC stack 10, condenser 11, water-gas separator 12, booster pump 13, high-pressure gas cylinder 14, flow meter 15, high-temperature circulation pump 16.

[0045] The blower 1, the air heat exchanger 2, the electric heater 3, and the air-gas heat exchanger 4 are connected in sequence to form a supply flow path on the cathode side. The fan 1 is used to compress the air and send it to the air heat exchanger 2; the air heat exchanger 2 is used to send the air sent by the fan 1 and the high-temperature cathode tail gas discharged from the SOEC stack 10 heat exchange; the electric heater 3 is used to heat the air; the air-gas heat exchanger 4 is used to exchange heat between the high-temperature air heated by the electric heater 3 and the wa...

no. 3 Embodiment approach

[0055] as attached Figure 4 As shown, a high-safety fuel cell electrolyzer system includes: fan 1, air heat exchanger 2, electric heater 3, air-gas heat exchanger 4, water tank 5, water pump 6, steam generator 7, gas Heat exchanger 8, ejector 17, SOEC stack 10, condenser 11, water-gas separator 12, booster pump 13, high-pressure gas cylinder 14, flow meter 15, valve 18.

[0056] The blower 1, the air heat exchanger 2, the electric heater 3, and the air-gas heat exchanger 4 are connected in sequence to form a supply flow path on the cathode side. The fan 1 is used to compress the air and send it to the air heat exchanger 2; the air heat exchanger 2 is used to send the air sent by the fan 1 and the high-temperature cathode tail gas discharged from the SOEC stack 10 heat exchange; the electric heater 3 is used to heat the air; the air-gas heat exchanger 4 is used to exchange heat between the high-temperature air heated by the electric heater 3 and the water vapor on the anode s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com