Spherical hinge permanent support and upper rotation construction method thereof

A technology of permanent bearing and spherical hinge bearing, applied in bridge parts, erecting/assembling bridges, bridges, etc., can solve the problems of easy cracking, excessive concrete age difference, time-consuming and laborious construction, etc., to avoid cracking, reduce The effect of dosage and shortening of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

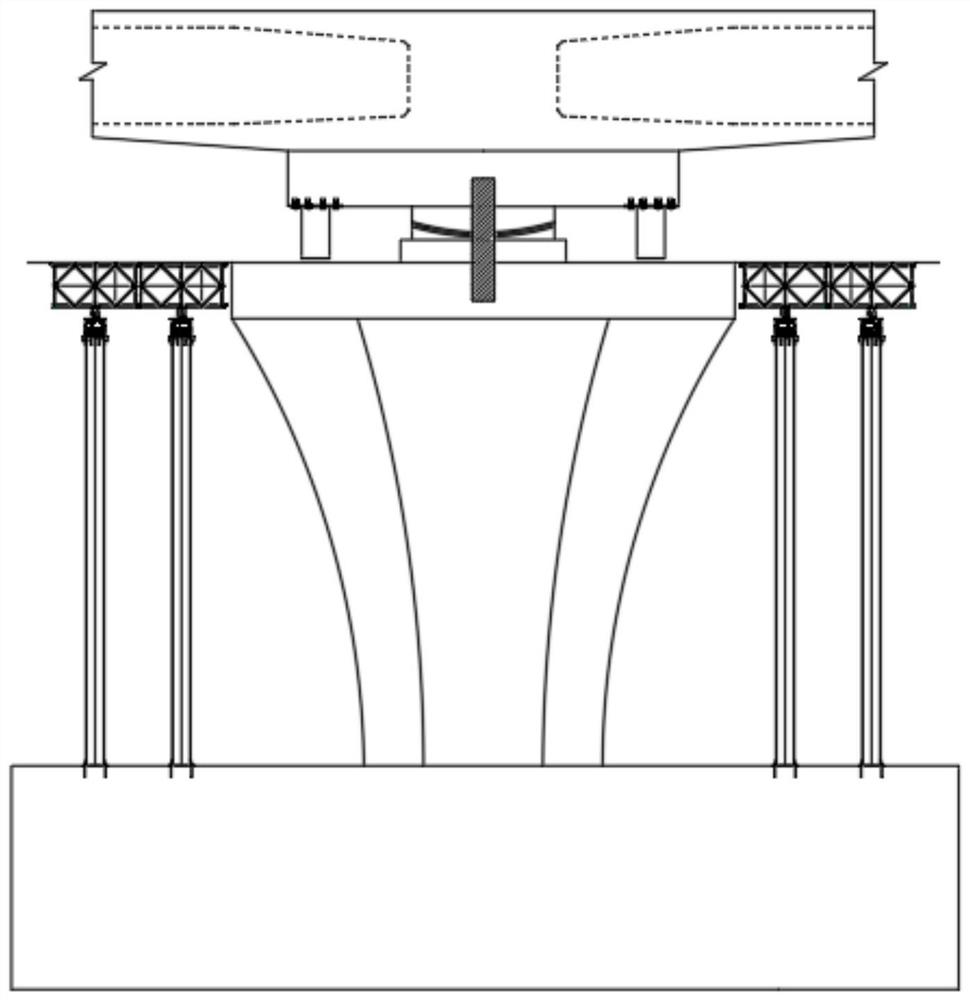

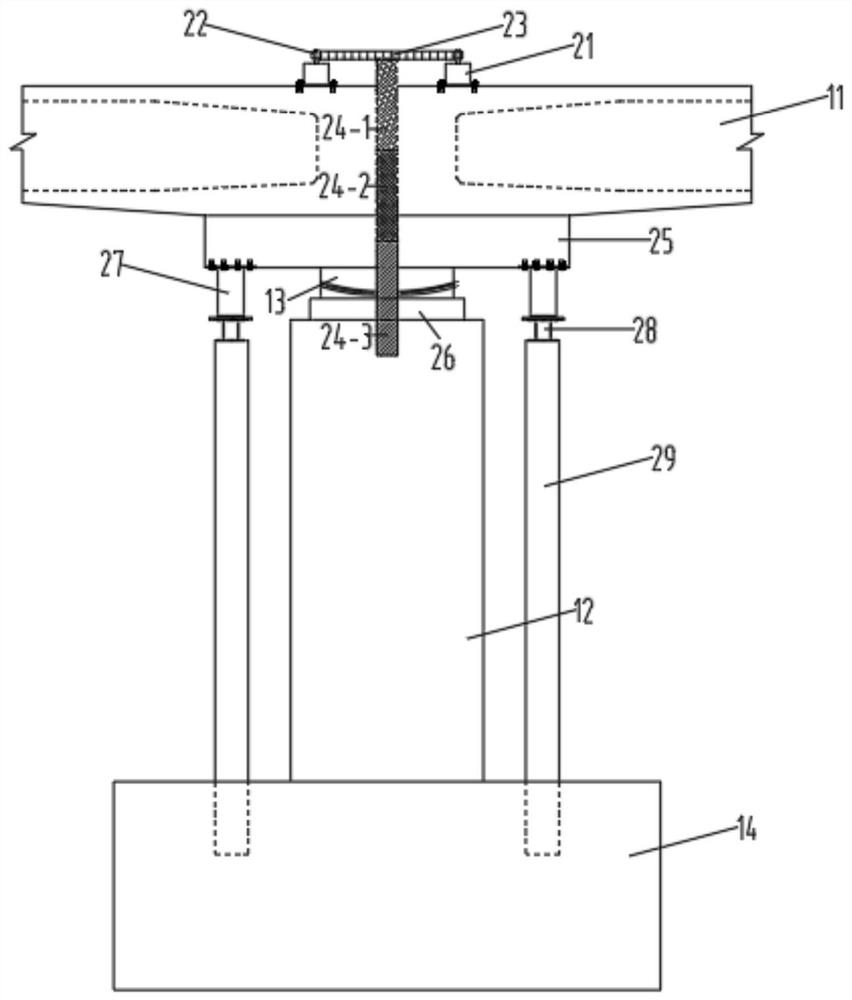

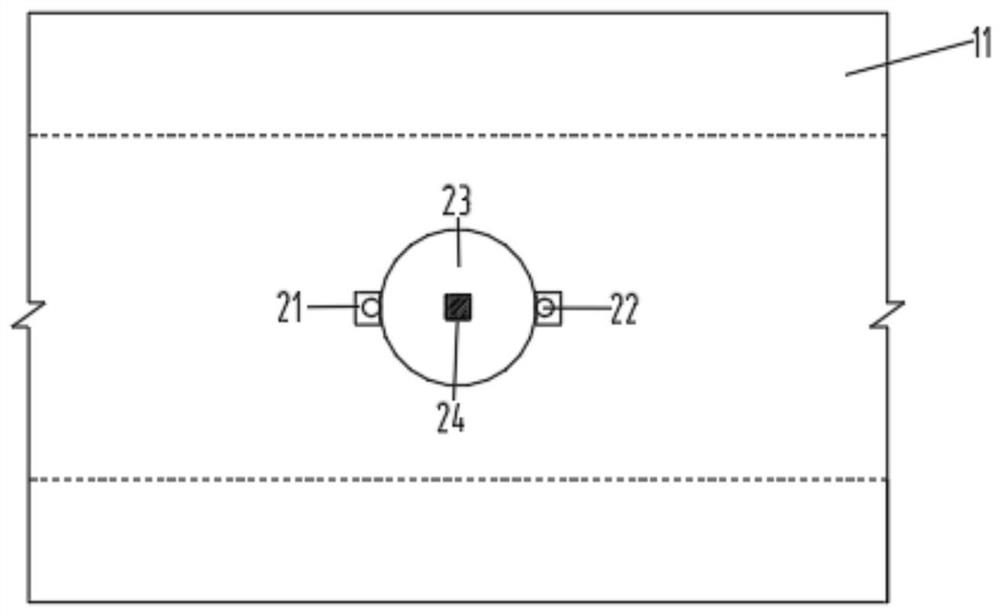

[0035] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0036] Such as Figures 2 to 4 As shown, the ball joint permanent bearing provided by the present invention includes an upper rotating assembly, a lower rotating assembly, a support, a transmission shaft assembly and a driving assembly; the upper rotating assembly and the lower rotating assembly are hinged through a ball joint bearing 13; the supporting member includes Support pin 27, slideway 28 and support tube 29, the lower end of several support tubes 29 is connected with the bottom of lower rotating assembly; Slideway 28 is ring structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com