Colored pervious concrete and preparation method thereof

A permeable concrete and color technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor durability, strength and water permeability of colored concrete, improve water permeability, improve strength and crack resistance, and increase viscosity. combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

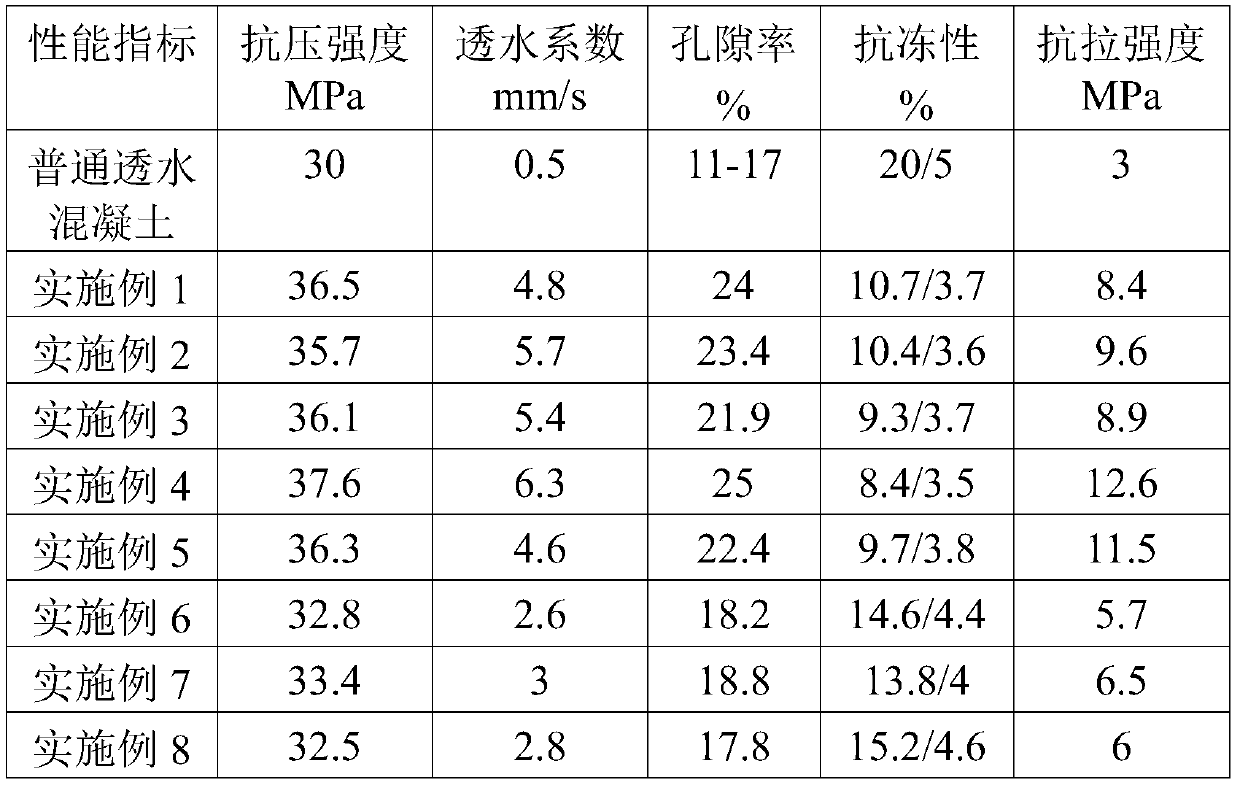

Examples

Embodiment 1

[0023] This embodiment provides a colored permeable concrete, which is made of the following components by weight: granite stone: 600 parts; admixture: 8 parts; cement: 200 parts; toner: 10 parts; water: 50 parts; Among them, the ingredients of the admixture are: 5% of fiber, 7.5% of rubber powder, 12% of silicon powder, 2% of water reducing agent, 35% of corundum, and 38.5% of quartz powder.

[0024] The preparation method of described colored permeable concrete comprises the following steps:

[0025] A. Mix the above-mentioned granite stone rice and the toner in the above parts by weight, add 40% of the above-mentioned water by weight after mixing evenly, and continue to stir evenly to obtain a mixture;

[0026] B, the cement of 40% by weight and the admixture of 40% by weight and the water of 30% by weight are stirred for 30s, obtain the first cement slurry;

[0027] C, adding the first cement slurry obtained in step B into the mixture obtained in step A, stirring for 1 mi...

Embodiment 2

[0033] This embodiment provides a colored permeable concrete, which is made of the following components by weight: granite stone: 600 parts; admixture: 8 parts; cement: 200 parts; toner: 10 parts; water: 50 parts; Among them, the ingredients of the admixture are: 5.5% of fiber, 7% of rubber powder, 10% of silicon powder, 4% of water reducing agent, 37.5% of corundum, and 36% of quartz powder.

[0034] Others are the same as embodiment 1

Embodiment 3

[0036] This embodiment provides a colored permeable concrete, which is made of the following components by weight: granite stone: 600 parts; admixture: 8 parts; cement: 200 parts; toner: 10 parts; water: 50 parts; Among them, the ingredients of the admixture are: 6.5% of fiber, 6% of rubber powder, 9% of silicon powder, 5% of water reducing agent, 34% of corundum, and 39.5% of quartz powder.

[0037] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com