Efficient energy-saving cold and heat supply station design system and method based on 3D/BIM foundation

A high-efficiency, energy-saving, system-design technology, applied in heating methods, air-conditioning systems, household heating, etc., can solve the problems of easy loss of thermal energy and affect the efficiency of thermal power plants, and achieve the effect of improving heating efficiency and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

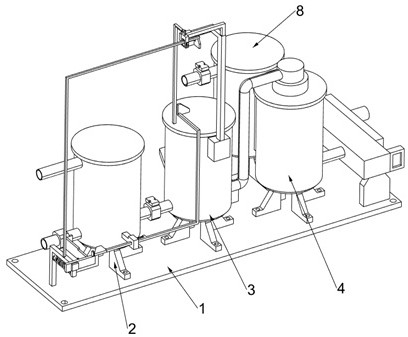

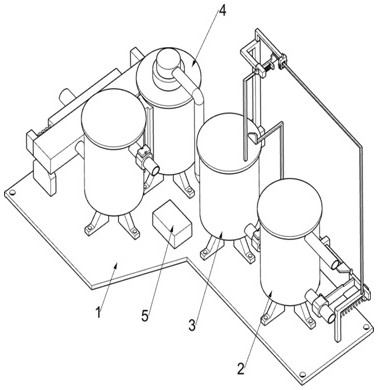

[0044] The design system and method of high-efficiency energy-saving cooling and heating station based on 3D / BIM, such as figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 7 As shown, it includes a bottom plate 1, a transfer tank 2, a return pipe 201, a heating tank 3, a hot water storage tank 4, a data storage control unit 5, a heating unit 6, a hot water storage unit 7, a cold water storage unit 8 and a constant temperature unit 80. The top surface of the bottom plate 1 on the left side is connected to the transfer tank 2 by means of fasteners, the top of the transfer tank 2 is connected to the return pipe 201, and the top surface of the bottom plate 1 on the right side of the transfer tank 2 is connected by fasteners The heating tank 3 for storing residual hot water is connected by means of the heating tank 3, and the top surface of the bottom plate 1 on the right side of the heating tank 3 is connected with the hot water storage tank 4 for storing hot water by fa...

Embodiment 2

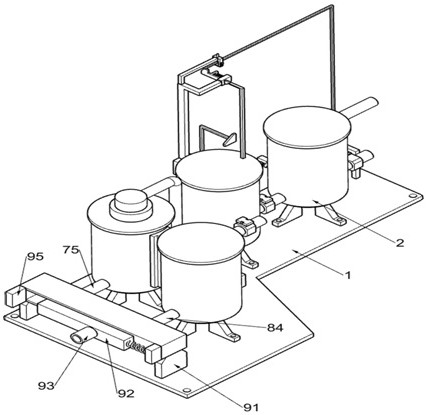

[0056] On the basis of Example 1, such as image 3 , Figure 8 and Figure 9 As shown, it also includes a liquid outlet adjustment unit 9, which is used to control the discharge of cold water and hot water. The right side of the bottom plate 1 is fixed with a liquid outlet adjustment unit 9, and the liquid outlet adjustment unit 9 includes The liquid guide frame 91, the movable liquid guide block 92, the drain pipe 93, the first tension spring 94 and the electromagnet 95, the liquid guide frame 91 is fixedly installed on the right side of the top surface of the bottom plate 1, and the liquid guide frame 91 is connected with the third conveying The right end of the tube 75 is connected, and the liquid guide frame 91 is also connected with the right end of the liquid outlet pipe 84. The liquid guide frame 91 is slidably connected with a movable liquid guide block 92, and the movable liquid guide block 92 is used to connect the third delivery pipe 75 or the liquid outlet pipe. ...

Embodiment 3

[0059] On the basis of Example 2, such as image 3 and 10 As shown, it also includes a floating adjustment part 10, the top of the heating tank 3 is slidably connected to the floating adjustment part 10, the floating adjustment part 10 includes a semi-circular floating plate 101 and an L-shaped push rod 102, and the top of the heating tank 3 is slidably connected to a The L-shaped push rod 102 is fixedly connected to the bottom end of the L-shaped push rod 102 with a semi-annular floating plate 101 , and the semi-annular floating plate 101 is located in the heating tank 3 .

[0060] Such as Figure 4 , Figure 11 and Figure 12 As shown, it also includes a limiting part 11, the heating tank 3 is provided with a limiting part 11, and the limiting part 11 includes a support block 111, a guide rod 112, a movable top plate 113, a second tension spring 114, a guide frame 115, a limiter Position bar 116 and limit spring 117, a support block 111 is fixedly installed above the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com