Grain dryer with gradient dehydration

A grain dryer and gradient dehydration technology, applied in dryers, drying, food processing, etc., can solve problems such as over-drying of grain, insufficient drying of grain, and different humidity, so as to save heat and avoid drying uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

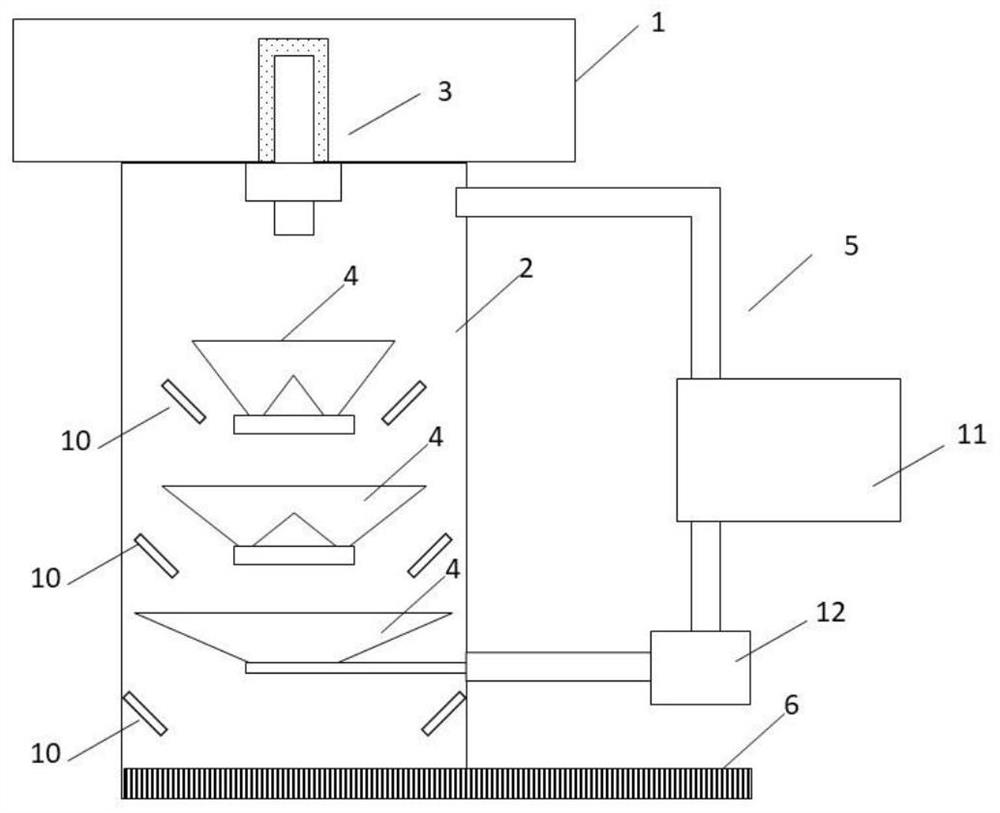

[0035] combine Figure 1-2 , a grain dryer for gradient dehydration, comprising a vibrating layerer 1, a drying controller, a drying tower 2, a grading feed head 3, a drying bucket 4, a hot air circulation system 5 and a bottom discharge conveyor belt 6;

[0036] The vibrating layerer 1 is arranged on the top of the drying tower 2, and is used to vibrate and layer the grains, so that the larger and heavier grains are in the lower layer, and the smaller and lighter grains are in the upper layer;

[0037] A grading feed head 3 is arranged at the bottom of the vibrating stratifier 1, and the grading feed head 3 is connected to the inner top of the drying tower 2, and is used to inject the grain in the vibrating stratifier 1 into the drying tower 2 according to the grade;

[0038]A drying bucket 4 is arranged in the drying tower 2, and the number of drying buckets 4 is multiple, and the drying bucket 4 performs gradient drying on the grain; the hot air circulation system 5 is arra...

Embodiment 2

[0051] The drying controller controls the feed switch of the grading feeding head 3 and the drying controller is connected to the humidity sensor of the drying hopper 4 to obtain the grain humidity in the following specific manner:

[0052] Before starting drying, inject the grain into the vibrating stratifier 1 at one time, control the grading feed head 3 to adjust to the highest position, and use vibration to stratify the grain, so that the larger and heavier grain is in the lower layer, and the smaller and lighter The grain is in the upper layer; during the drying process, no grain is added to the vibrating layerer 1;

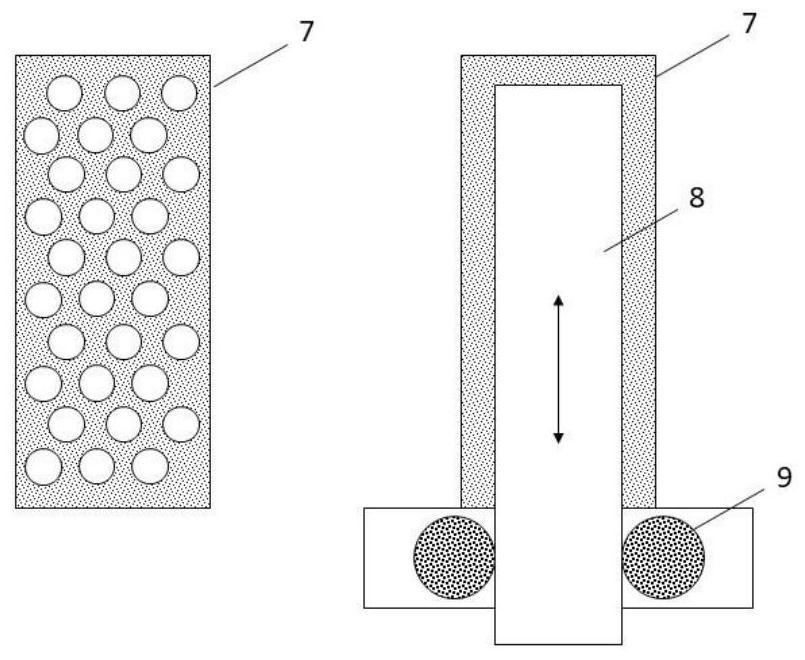

[0053] Start drying, the inner pipe 8 of the grading feed head 3 moves down a certain distance, so that the grain enters the drying bucket 4 on the uppermost layer;

[0054] The uppermost drying bucket 4 starts to vibrate and dry; the drying controller collects the grain humidity at the outer edge of the side wall of the uppermost drying bucket 4, and if the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com