Method for positioning open-circuit fault of upper tube of half-bridge sub-module of modular multilevel converter

A modular multi-level, half-bridge sub-module technology, applied in the field of power electronics, can solve problems such as rising and inability to identify faulty sub-modules, and achieve the effects of reducing possibilities, reducing hardware costs, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

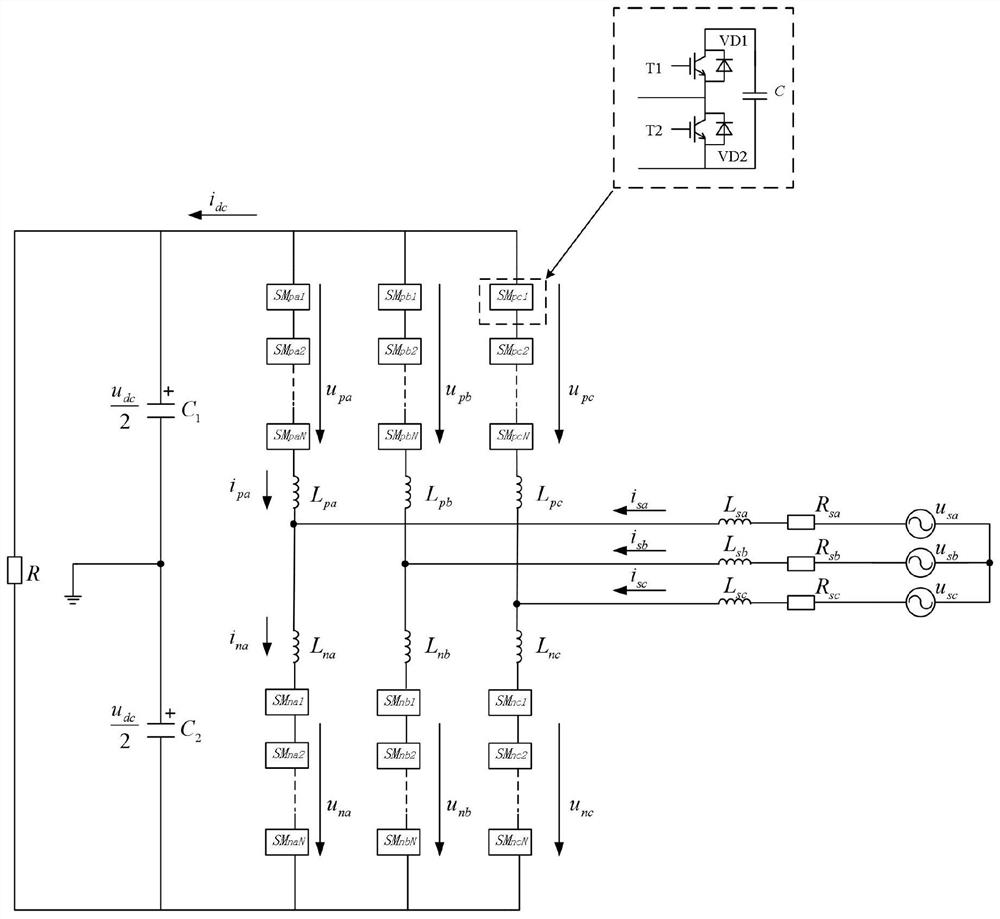

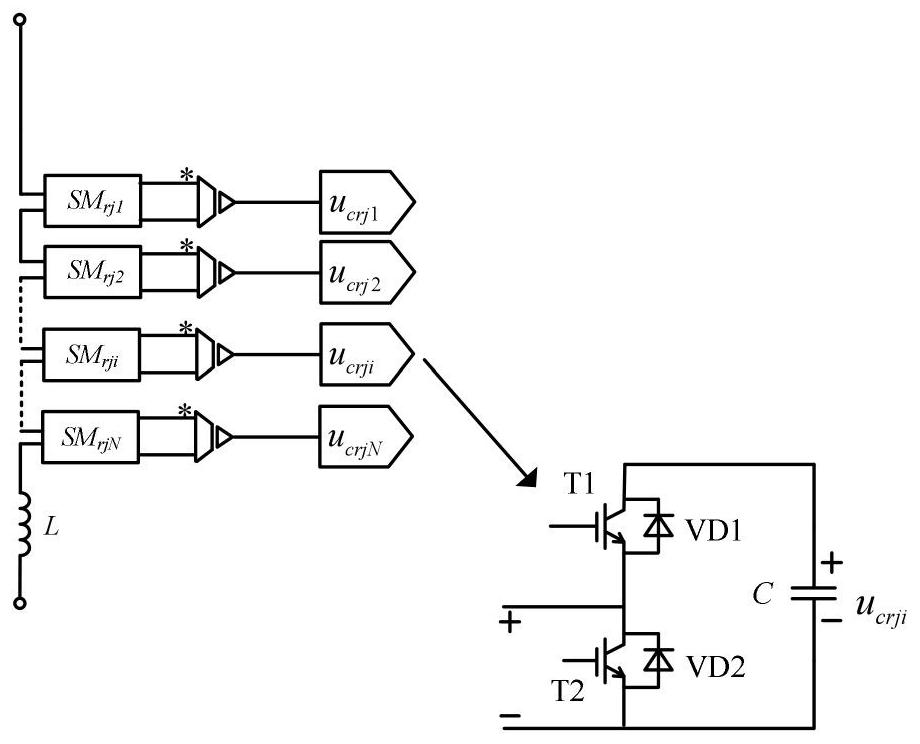

[0035] figure 1 It is the main circuit topology diagram of the three-phase modular multilevel converter. The three phases a, b, and c are highly symmetrical. Each phase is composed of two upper and lower bridge arms. There are six bridge arms in the three phases. The upper and lower bridge arms of each phase are also symmetrical, and each bridge arm is composed of N half-bridge sub-modules SM rji (r=p,n; j=a,b,c; i=1,2,3,...N) and a bridge arm inductance L rj (r = p, n; j = a, b, c) in series. Each sub-module is a half-bridge structure, and each half-bridge sub-module is composed of two switching devices T1 and T2 and a capacitor C connected in parallel, wherein the two switching devices T1 and T2 are respectively connected in antiparallel with a diode VD1 and VD2. The first sub-module SM of the upper bridge arm of the three-phase pj1 The emitters of the T1 tubes are connected together and connected to the positive end of the DC bus; the last sub-module SM of the three-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com