Thermal compensation method for combustion chamber of rapid compressor

A combustion chamber and compressor technology, which is applied in mechanical equipment, machines/engines, liquid variable displacement machinery, etc., can solve problems such as unavoidable heat dissipation, temperature and pressure drop in the combustion chamber, and differences in the degree of influence by heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0049] refer to Figure 1-6 , a method for fast compressor combustion chamber heat compensation, comprising the following steps:

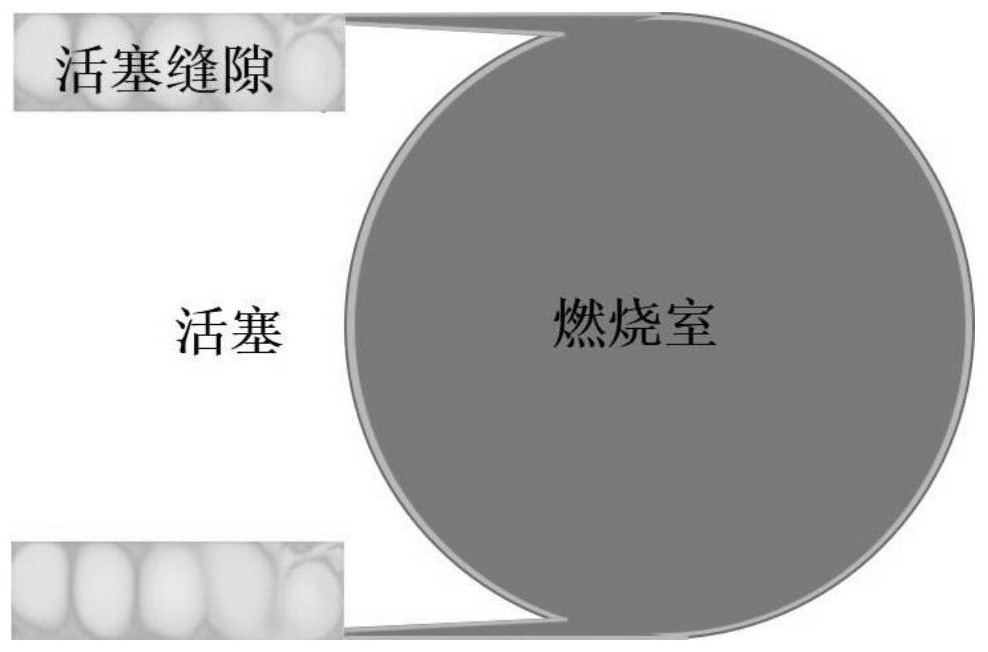

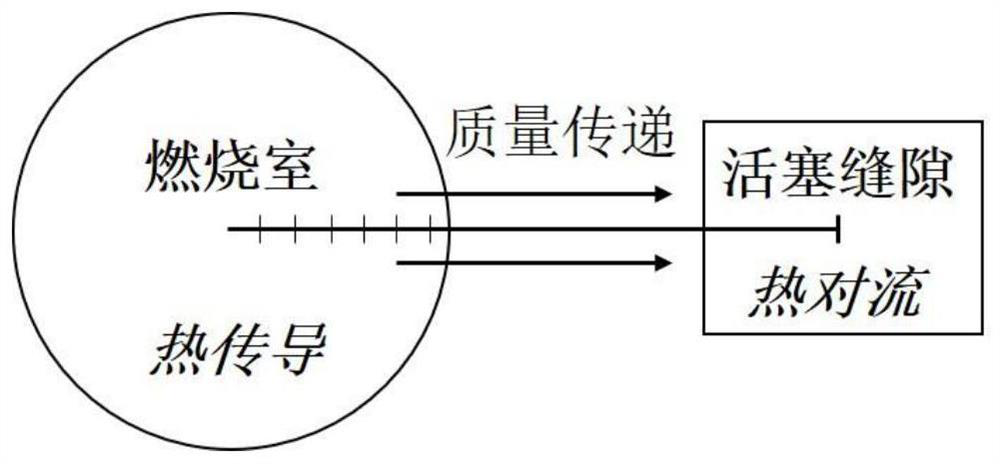

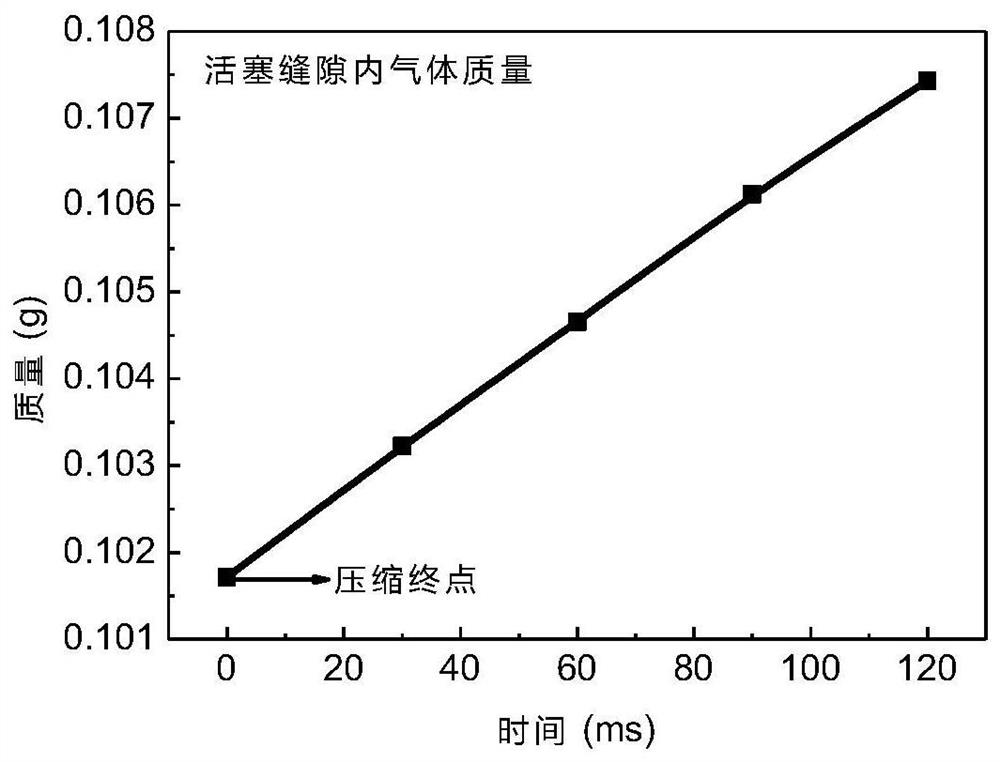

[0050] Step 1. Establish a heat dissipation model of the fast compressor. The calculation domain of the heat dissipation model includes the combustion chamber and the gap between the side wall of the combustion chamber and the piston.

[0051] The combustion chamber of the fast compressor communicates with the gap between the piston and the compression cylinder wall. The piston gap contains the boundary layer gas in the volume swept by the piston during the compression process, suppresses the vortex generated by the high-speed movement of the piston, and increases the temperature in the combustion chamber. Uniformity.

[0052] The gap formed due to the deform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com