Industrial mineral aggregate conveying belt material shortage abnormity monitoring method based on machine vision

A conveyor belt, abnormal monitoring technology, applied in the direction of instruments, computer parts, image data processing, etc., can solve the problems of poor accuracy, high work intensity of staff, and inability to monitor the abnormality of industrial mineral material conveyor belts with few materials. The effect of reducing work intensity, reducing abnormal factors, and fast recognition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0078] The present invention aims at the existing anomaly monitoring method with high work intensity of the staff, and cannot accurately monitor the abnormality of the small amount of material in the industrial mineral material transportation belt. Interference makes it impossible to accurately extract the area of interest of the belt, and there are many factors affecting the abnormal operation of the industrial mineral material transportation belt. The monitoring method for belt less material abnormality.

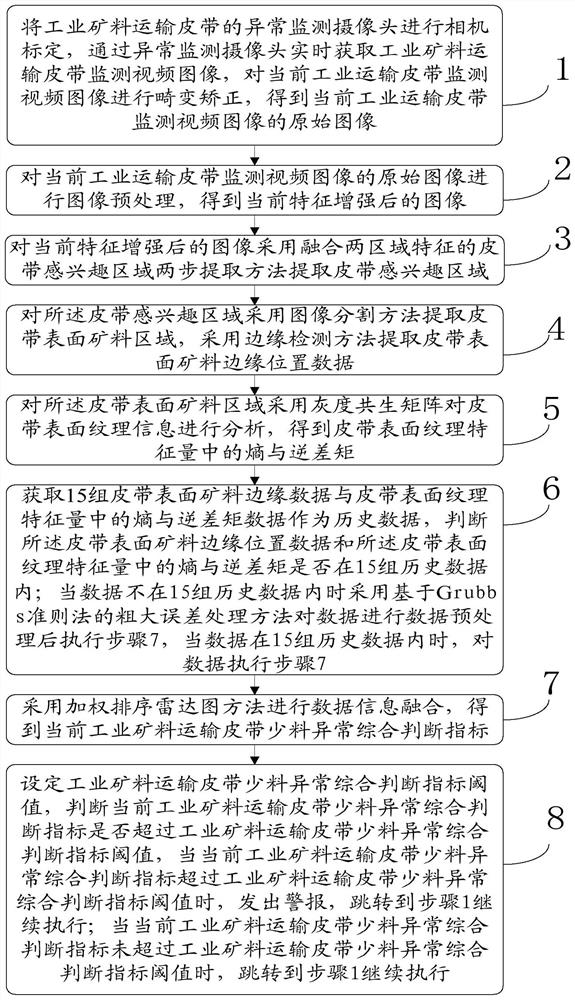

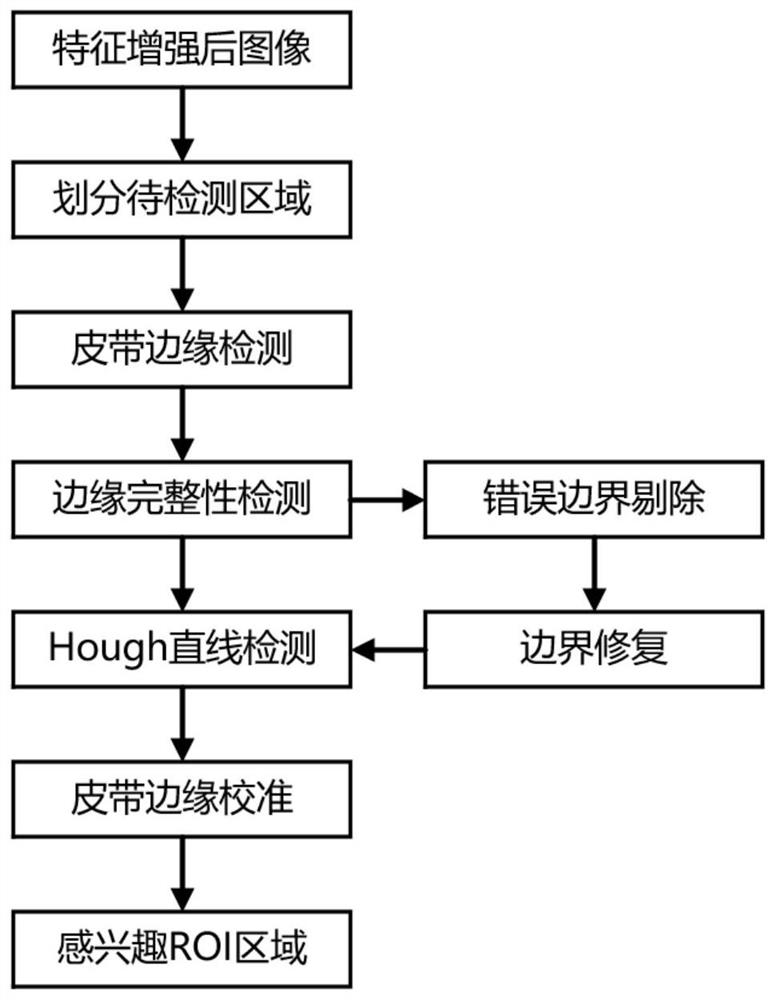

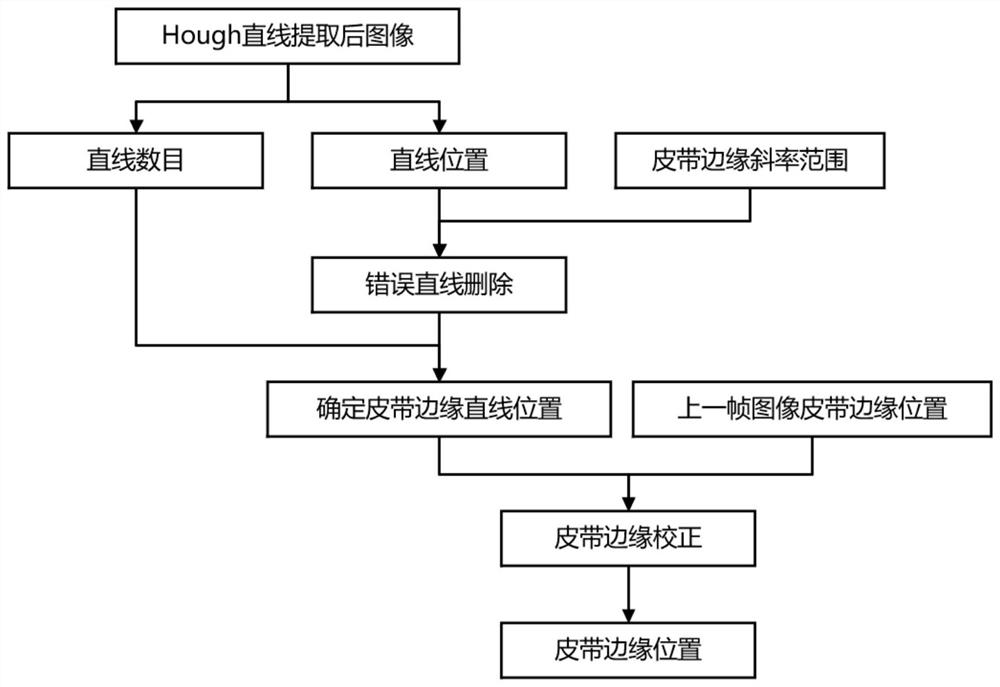

[0079] Such as Figure 1 to Figure 8As shown, the embodiment of the present invention provides a machine vision-based method for monitoring the abnormality of the industrial mineral material transportation belt with less material, including: step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com