Gradient lifting method well cementation quality evaluation method

A quality evaluation and method cementing technology, which is applied in the directions of measurement, earthwork drilling and production, borehole/well components, etc., and can solve the problems of poor timeliness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

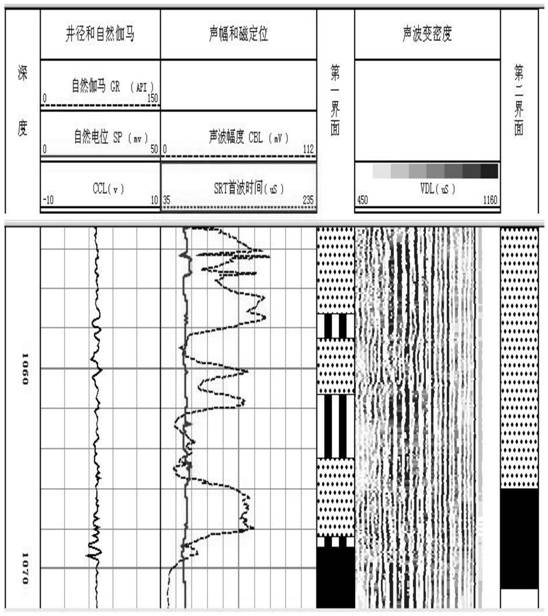

[0059] like Figure 1 to Figure 4 As shown, a gradient lifting method cementing quality evaluation method specifically includes the following steps:

[0060] S1 Establishing a sample set: selecting a sample well, performing discrete data sampling on the cementing quality evaluation results of the sample well to obtain a sample set;

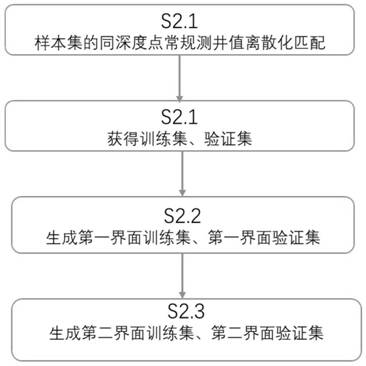

[0061] S2 establishes a training set and a verification set: perform discretization matching on the sample set established in step S1 with conventional logging values at the same depth point, and randomly separate a certain proportion of the sample set data from the matched sample set data as the training set. The sample set data below is the validation set;

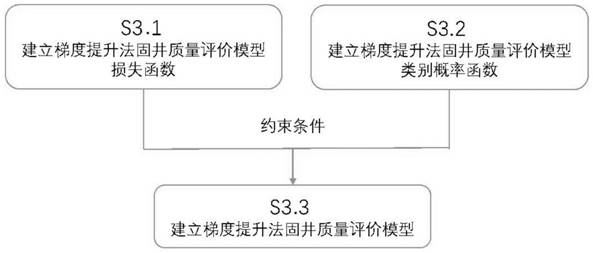

[0062] S3 establishes the primary model of cementing quality evaluation by gradient lifting method: conventional logging values are used as input data, cementing quality evaluation results are used as output data, and loss function and class probability function are used as algorithm co...

Embodiment 2

[0102] This embodiment is similar to Embodiment 1, except that, in this embodiment, the target value of the coincidence rate is 99%, and the coincidence rate of the verification set is 90%. Other parts and working principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0104] This embodiment is similar to Embodiment 1, except that, in this embodiment, the target value of the coincidence rate is 99%, and the coincidence rate of the verification set is 99%. Other parts and working principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com