Intelligent on-load gas exhaust device of transformer

A technology of exhaust device and transformer, which is applied in the direction of transformer/inductor circuit, valve device, signal device, etc., can solve the problems of high workload of personnel, potential safety hazards, low degree of automation of gas exhaust operation, etc., and achieve convenience, Solve the problem of starting and stopping and ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

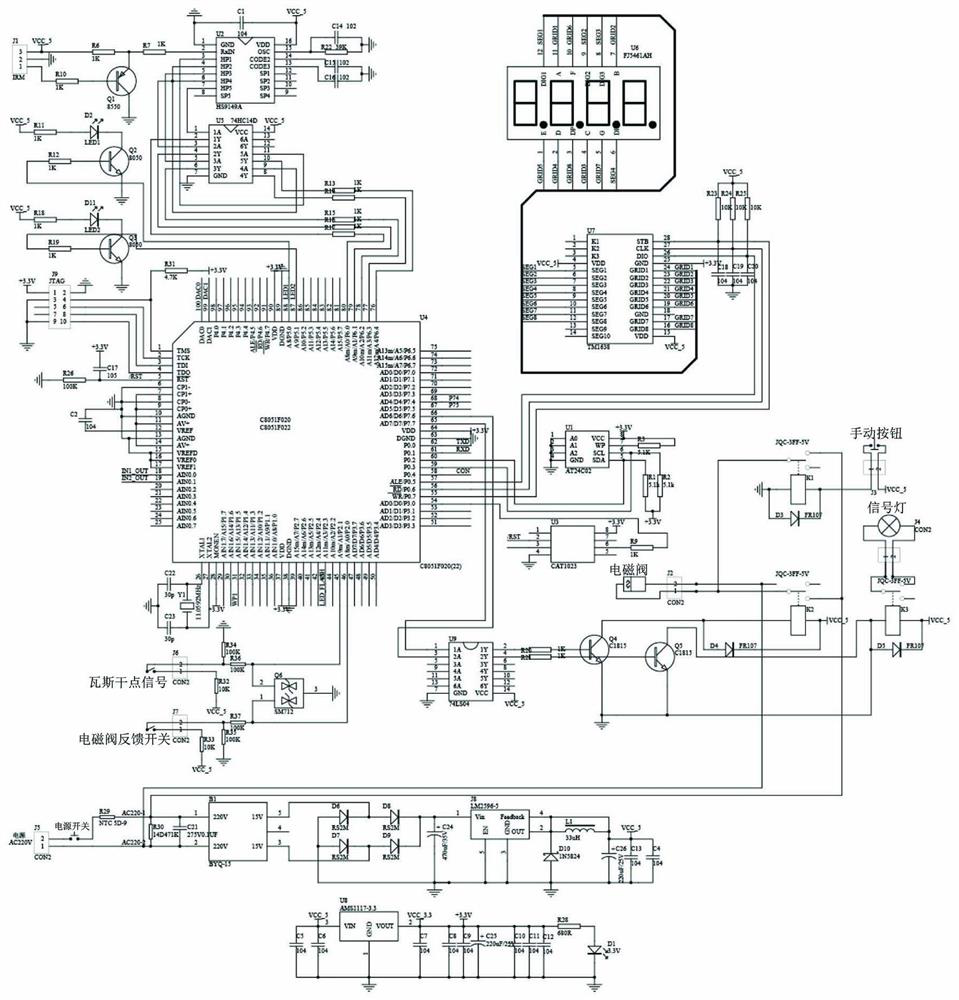

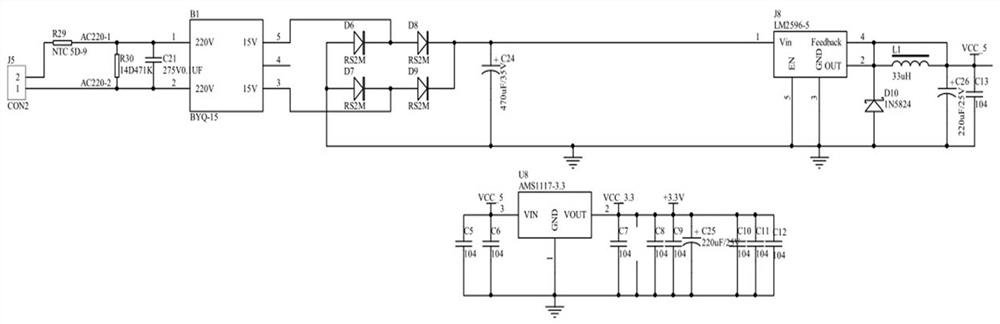

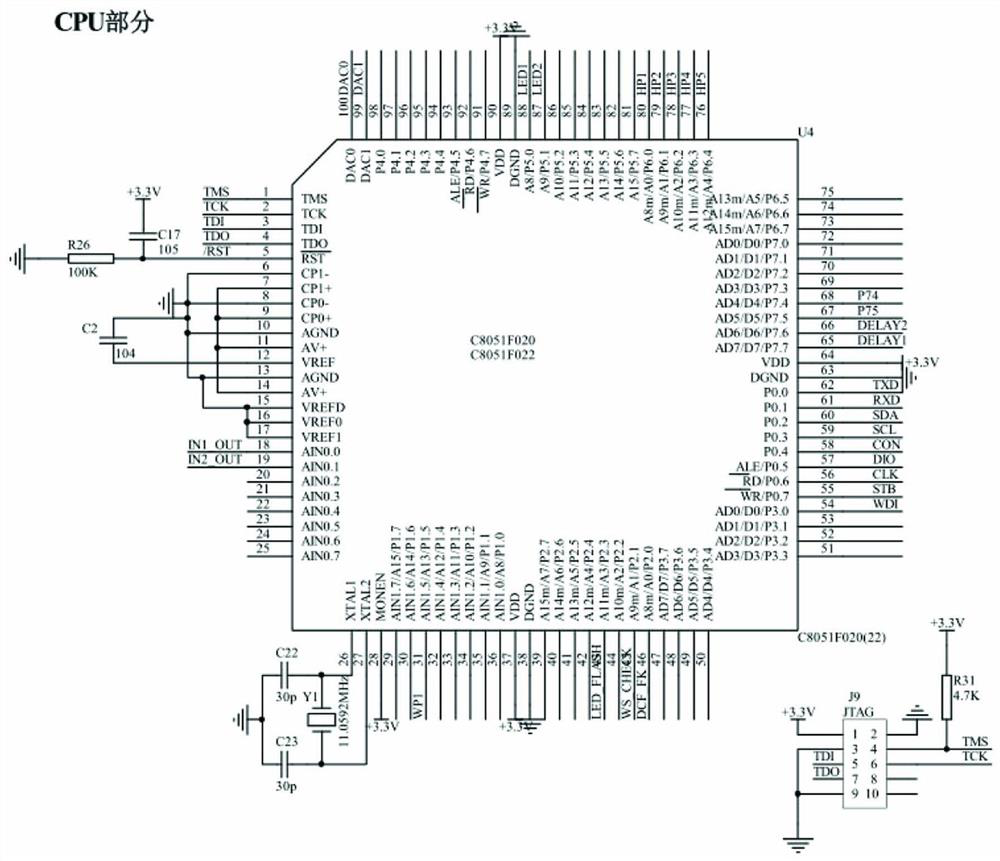

[0031] This device is a supporting device for the gas relay, mainly composed of the gas action module (CPU part), the gas relay deflation module and the light gas protection action module (output circuit area):

[0032] 1) According to the reason of transformer gas action in the past and the structure of the transformer, it can be seen that the probability of gas gas generation in the main transformer body is small, and the operation of the on-load tap-changer is relatively frequent, so the exhaust device should consider the discharge of gas on load as much as possible;

[0033] 2) The exhaust device of the gas relay is connected to the ground with a hard pipeline for exhaust, and the solenoid valve is oil-resistant;

[0034] 3) The loop controls the solenoid valve to start the exhaust, and the reasonable use of the timing of the time relay can ensure that the discharge is not mistaken;

[0035] 4) By setting the intermediate relay ZJ (K1, K2, K3), the light gas alarm of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com