An integrated integrated motor system

An integrated and integrated technology, applied in the direction of mechanical equipment, electric components, electromechanical devices, etc., can solve the problems of high failure rate of the drive motor controller, heating of the drive motor controller, serious problems, etc., and achieve simple wiring of the motor system, The effect of reasonable structure design and novel design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

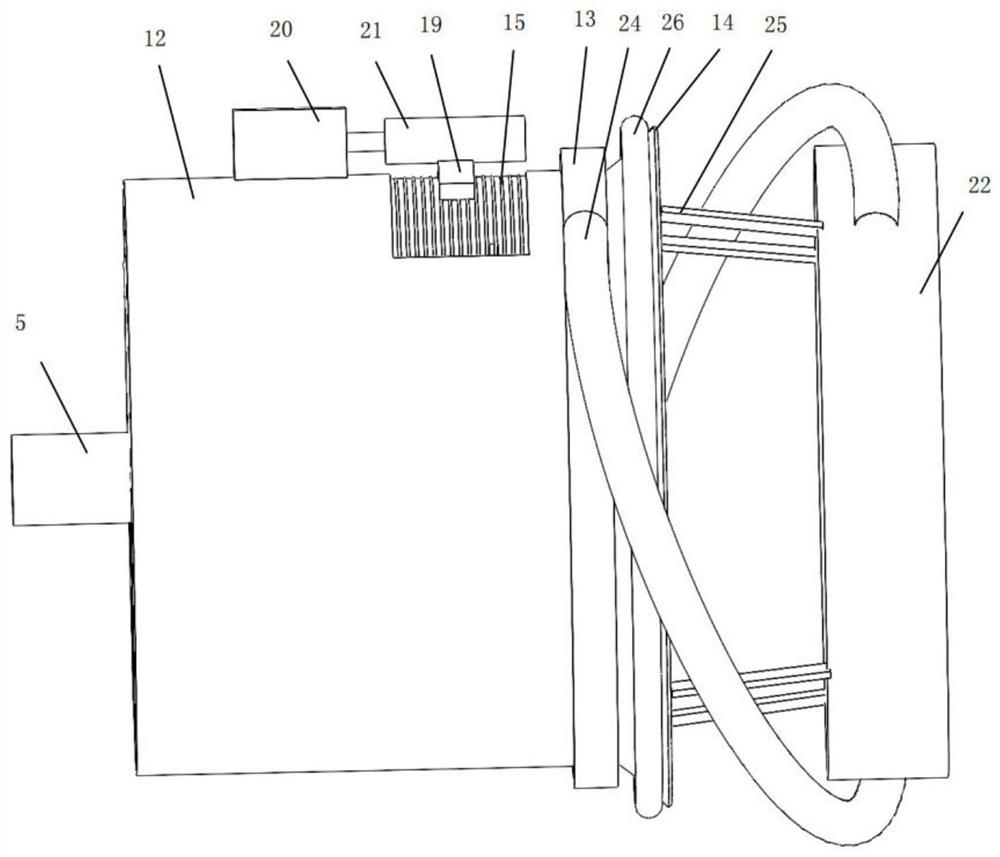

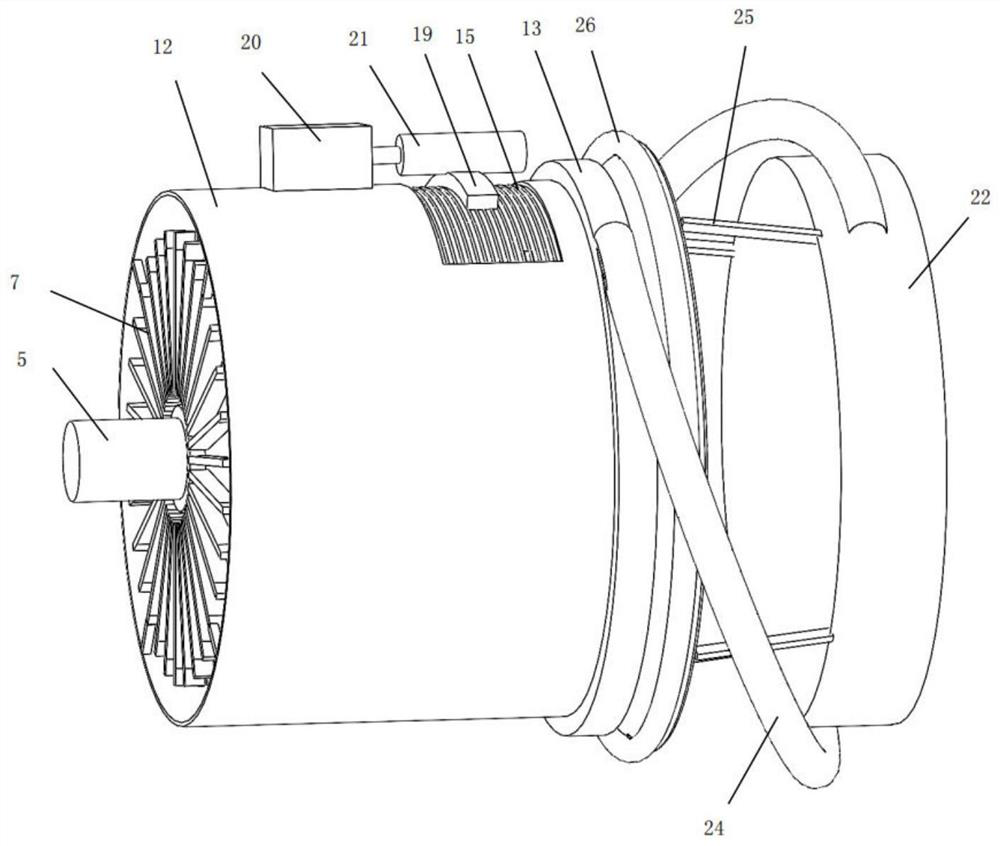

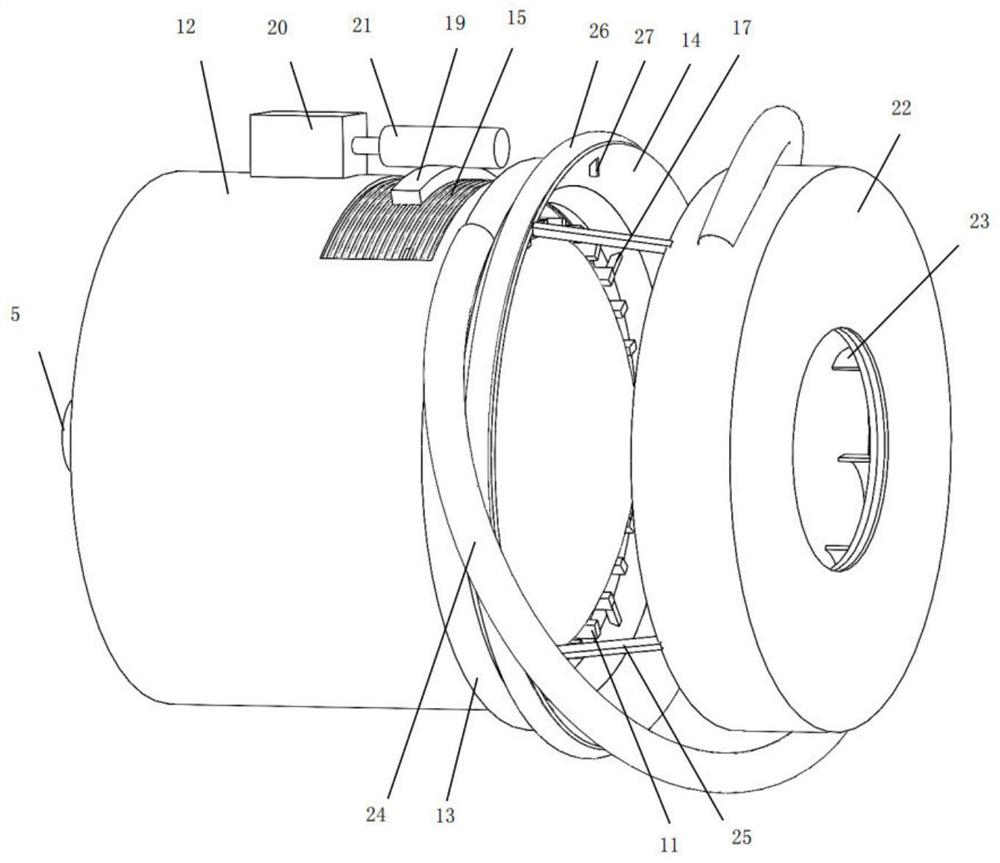

[0034]Hereinafter, the technical solutions of the present invention will be described in detail by way of embodiments with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention.

[0035] The term "and / or" in this article is only an association relationship to describe associated objects, indicating that there can be three kinds of relationships, for example, A and / or B, which can mean: A alone exists, B alone exists, and A and B exist simultaneously. There are three cases of B. In this article, the term " / and" is to describe another related object relationship, which means that there can be two relationships, for example, A / and B, which can mean that A exists alone, and A and B exist alone. , In addition, the character " / " in this text generally indicates that the related objects are an "or" relationship....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap