Device for driving a shaft of a jet engine for inspection purposes

A technology of jet engines and equipment, applied in mechanical equipment, engine functions, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

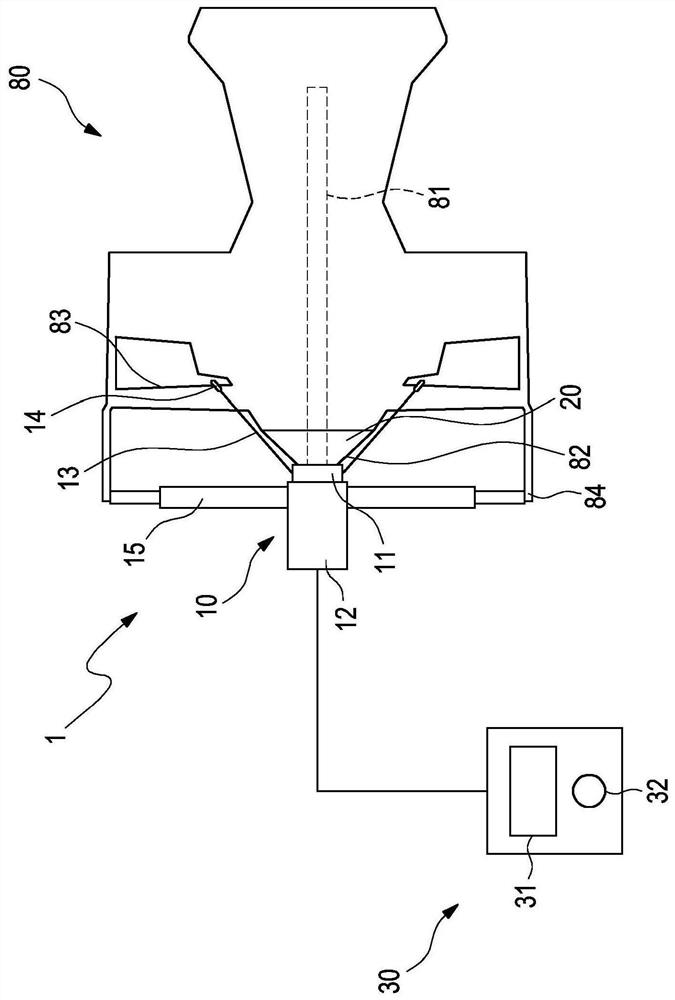

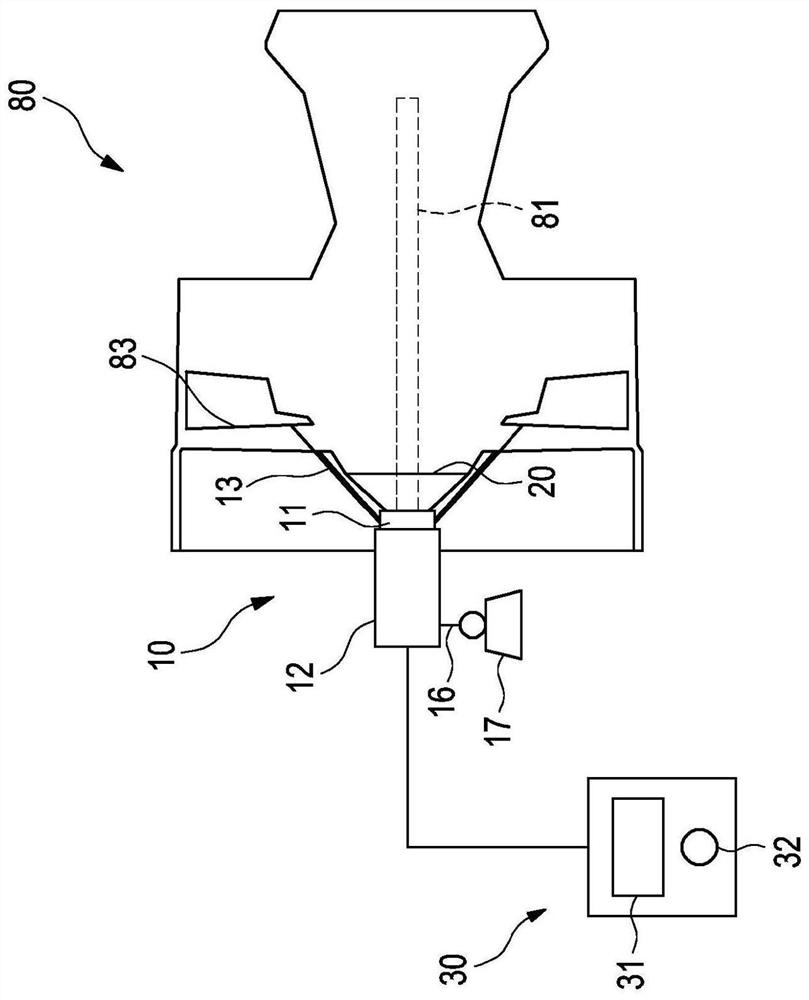

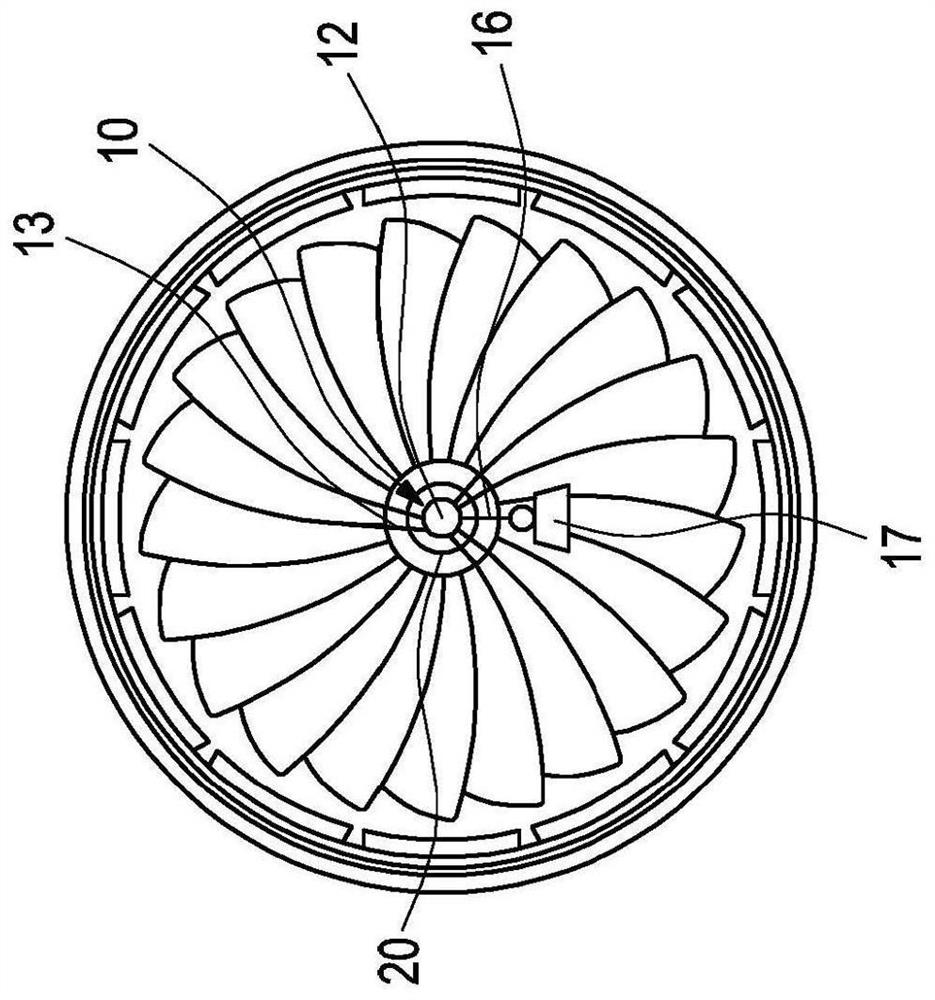

[0041] exist figure 1 In , a first embodiment of the device 1 of the invention is shown.

[0042] The device 1 is designed to drive a shaft 81 of a jet engine 80 , the rotor 82 of which is the visible so-called nose cone of the jet engine 80 from the outside, on which fan blades 83 are fastened in a rotationally fixed manner.

[0043] The device 1 comprises a drive unit 10 having two parts 11 , 12 rotatable relative to each other, one part 11 co-rotating with the shaft 81 of the jet engine 80 and the other part 12 not co-rotating therewith.

[0044] The co-rotating part 11 is designed to bear against the rotating part 82 of the shaft 81 and for this purpose has a negatively shaped contact surface matching the shape of the rotating part 82 . In order to increase the adhesion between this contact surface and the rotating part 82, between the co-rotating part 11 of the drive unit 10 and the rotating part 82 there is provided an adhesion-improving element 20 made of an elastomer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com