Metal product recycling treatment system

A metal product and processing system technology, applied in the direction of grain processing, manufacturing tools, presses, etc., can solve the problems of inability to grade metal products, low crushing efficiency, poor applicability, etc., to improve the crushing effect and efficiency of crushing, The effect of improving crushing efficiency and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

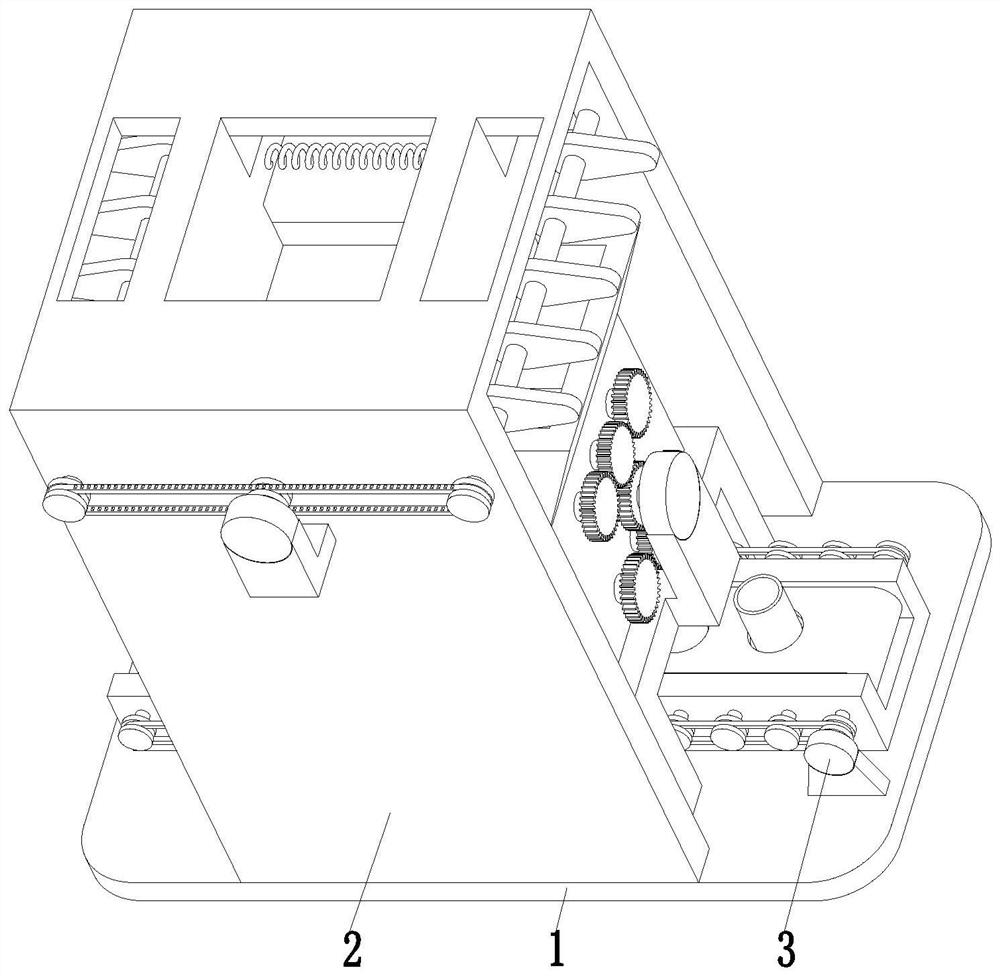

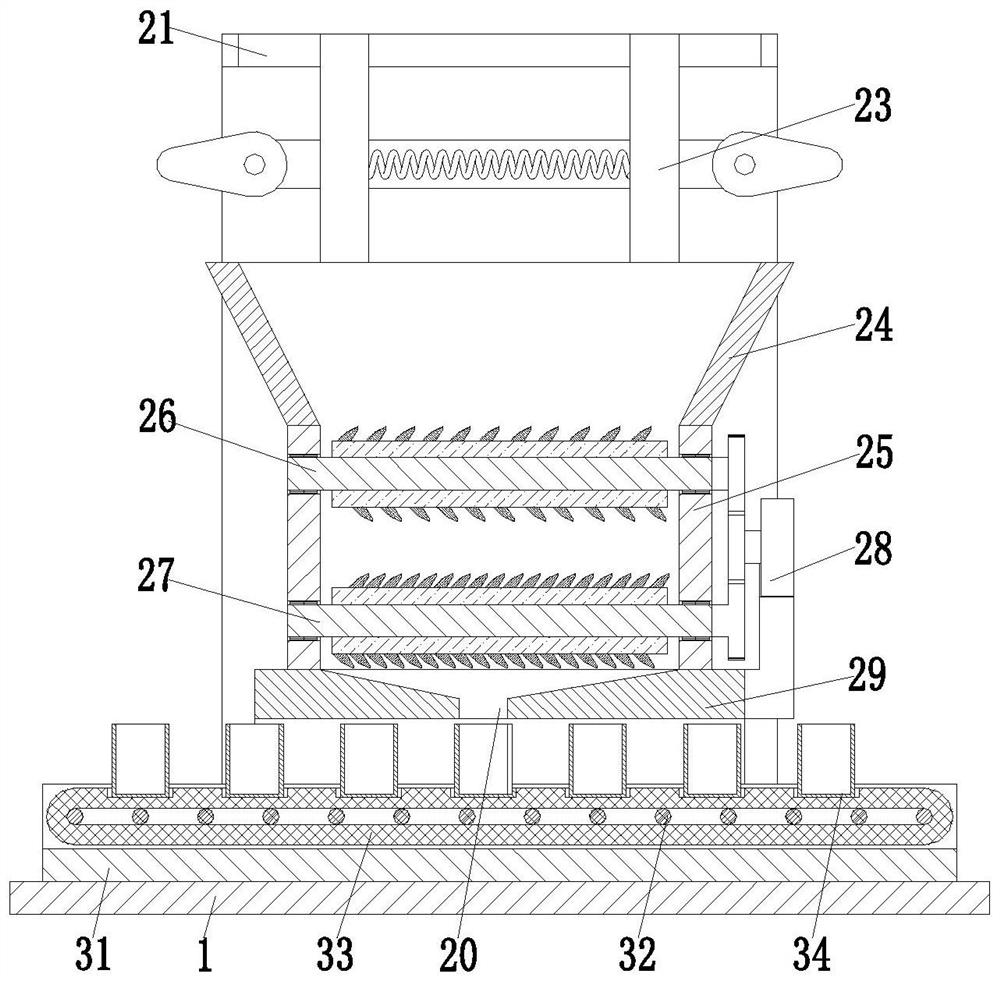

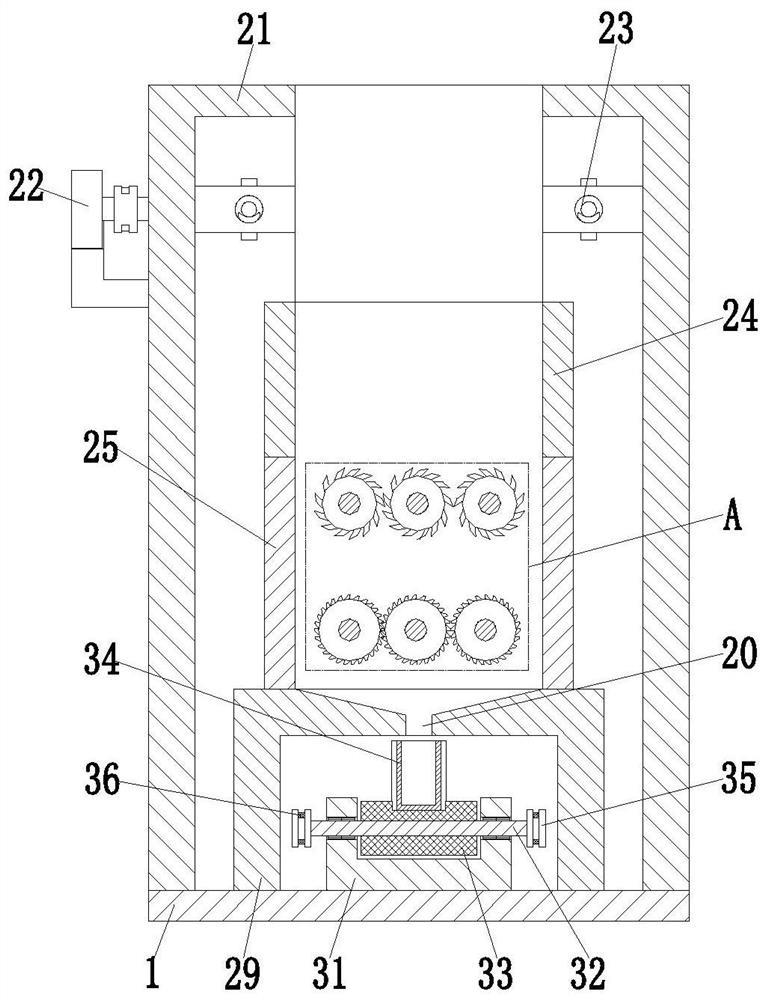

[0027] Such as Figure 1 to Figure 6 As shown, a metal product recovery and reuse processing system includes a base plate 1, a recovery processing device 2 and a conveying and collecting device 3. A recycling processing device 2 is installed in the middle of the upper end surface of the bottom plate 1, and a conveying device 2 is installed below the recycling processing device 2. The collection device 3 is installed in the middle of the upper end surface of the bottom plate 1 .

[0028] The recovery processing device 2 includes a support frame 21, a driving mechanism 22, an extrusion mechanism 23, a feed box 24, a crushing box 25, a primary crushing mechanism 26, a secondary crushing mechanism 27, a power mechanism 28, and a shape plate 29 And the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap