Ovality adjusting tool for flange of wind power tower drum and manufacturing and application method of ovality adjusting tool

A technology of a wind power tower and an application method, which is applied to auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high input cost, low adjustment efficiency and adjustment accuracy of tooling, reduce labor and processing costs, and achieve effective Control and apply convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

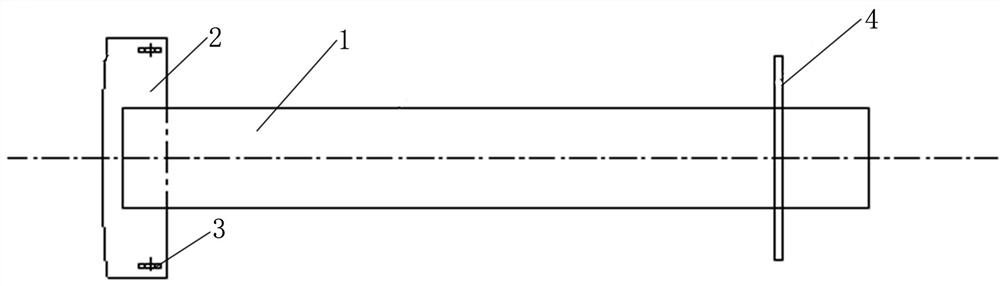

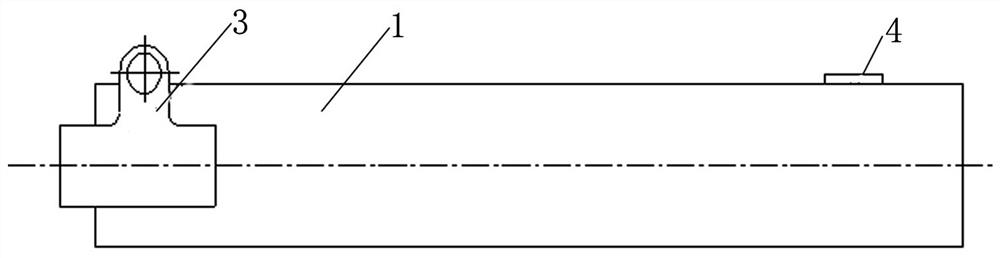

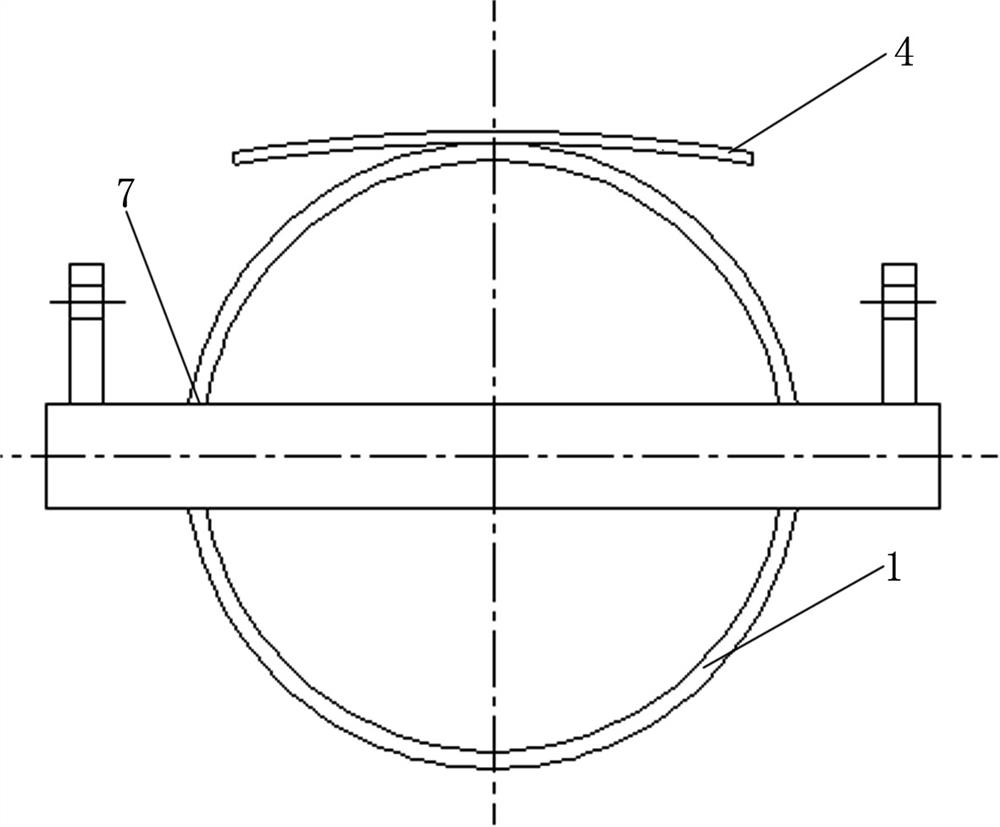

[0027] see Figure 1 ~ Figure 3 As shown, it shows a wind power tower flange ellipticity adjustment tool, including a hollow correction support tube 1, a correction plate 2, a lifting lug 3 and an arc gasket 4, and the outside of the correction plate 2 is square and symmetrical on both sides There is a lifting lug 3, and one end of the hollow correction support tube 1 is provided with a notch 7 that is engaged with the correction plate 2, and one end of the correction plate 2 is locked and fixed with one end of the hollow correction support tube 1 through the notch 7, and the hollow correction support tube The other end side wall of 1 is fixed with an arc-shaped spacer 4 for limiting the hollow correction support tube 1, and the other end of the correction plate 2 is an arc-shaped structure.

[0028] Specifically, the tooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com