Forward and reverse rotation drill rod

A technology of forward and reverse rotation and drill pipe, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., and can solve the problems of thread processing error affecting the connection of drill pipe, flushing fluid affecting the stability of the connection, and difficult control of spline phase accuracy, etc. , to avoid dislocation of drill pipe connection, high strength of drill pipe connection and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

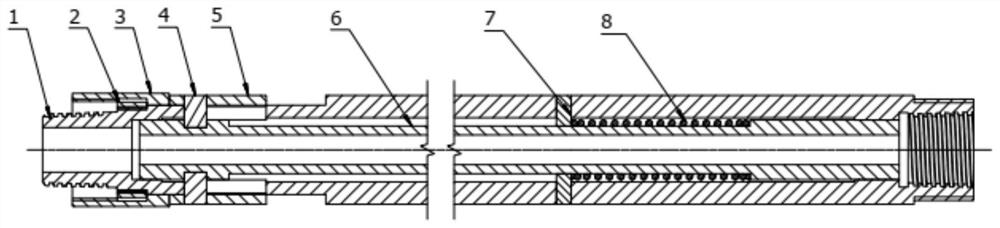

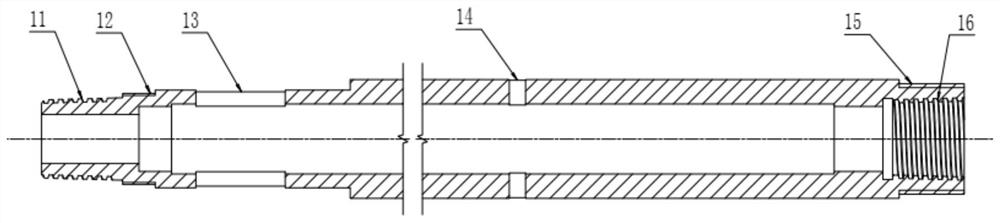

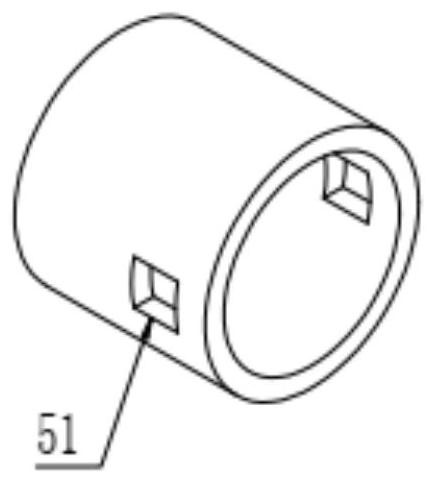

[0041] A forward and reverse drill pipe includes a drill pipe body 1 , a limit sleeve 2 , a reverse thread sleeve 3 , a drive pin 4 , a sliding sleeve 5 , a limit inner tube 6 , a spring limit block 7 and a spring 8 . The detailed structure and relative positional relationship of each component are as follows:

[0042] Drill pipe body 1: It is the main body of the drill pipe, which bears the torque during drilling, and is also the carrier of the threaded connection; the two ends are respectively provided with a male thread 11 and a female thread 16; the adjacent drill pipes pass through the male thread 11 The connection with the female head thread 16 realizes the connection of the drill pipe and the transmission of torque.

[0043]The front end of the drill pipe body 1 is provided with a limit thread 12 adjacent to the male thread 11 to be threaded with the limit sleeve 2. After the reverse threaded sleeve 3 is loaded, the drill pipe body 1 is threaded with the limit sleeve 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com