Shot blasting machine and shot blasting process

A shot blasting machine and frame technology, which is used in manufacturing tools, metal processing equipment, abrasive jet machine tools, etc., can solve problems such as mesh blockage, and achieve the effect of improving the purity, the shot blasting effect is not easy to decline, and the purity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

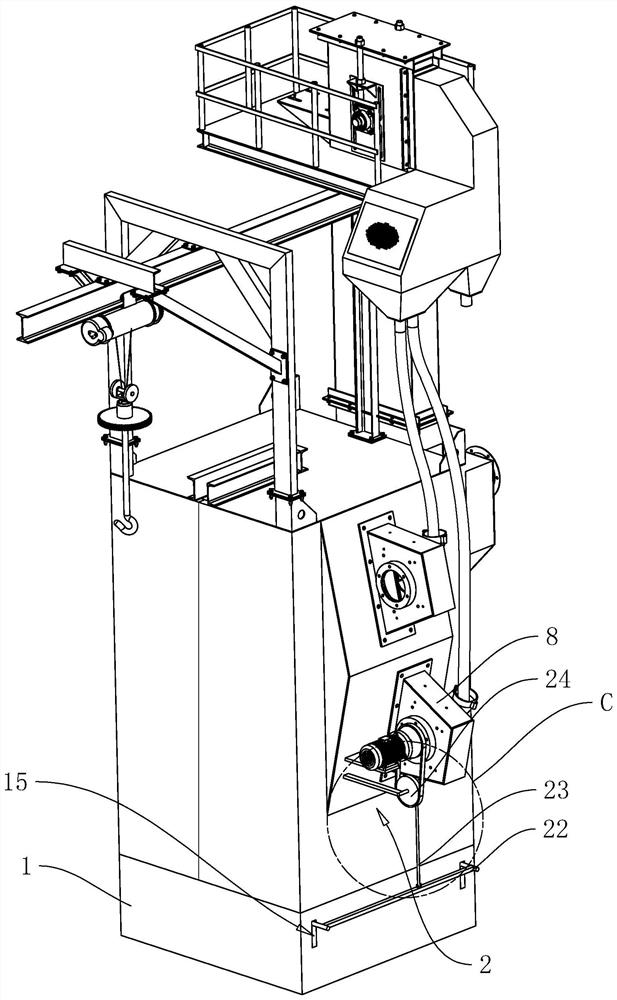

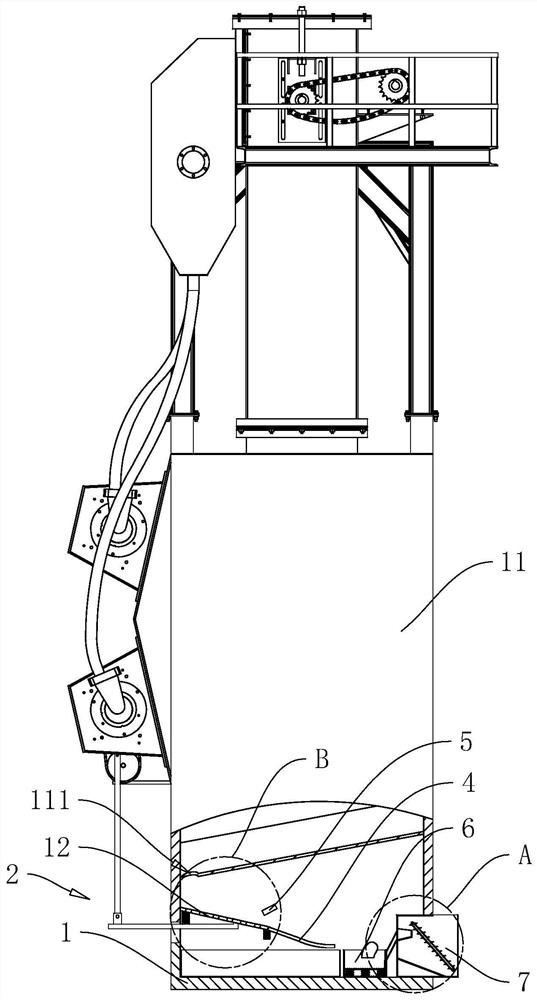

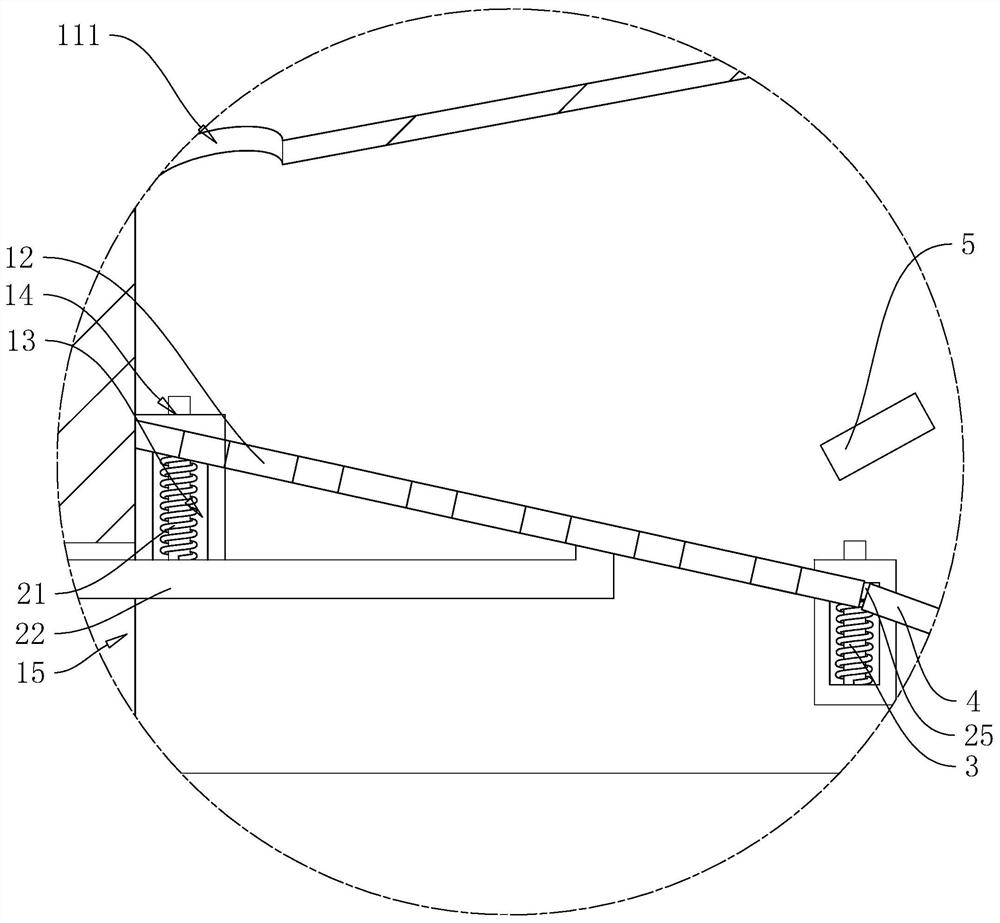

[0042] Attached to the following Figure 1-5 This application will be described in further detail.

[0043] The shot blasting machine includes a frame 1. The frame 1 is provided with a shot blasting box 11 and a shot blasting device 8. The bottom wall of the shot blasting box 11 is inclined, and a chip discharge port 111 is opened at the lower end of the bottom wall of the shot blasting box 11. The rack 1 located below the chip outlet 111 is provided with a filter screen 12, and the rack 1 under the filter screen 12 is fixedly installed with a recovery box with an upper opening. The vertical projection of the filter screen 12 is located in the recovery box, and the filter screen 12 A projectile box 6 with an upper opening is fixedly installed on the frame 1 at the lower end of the filter screen 12, and the complete projectile rolled from the filter screen 12 rolls down into the projectile box 6 under the action of inertia, and the projectile in the projectile box 6 will be re-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com