A demoulding method and injection molding machine for plastic molding

A technology of plastic molding and demolding, applied in the field of plastic molding, can solve the problems of damage to the shape of injection molded parts, surface scratches, damage to the structure of tableware, etc., and achieve the effects of reducing difficulty, improving production efficiency, and improving demolding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

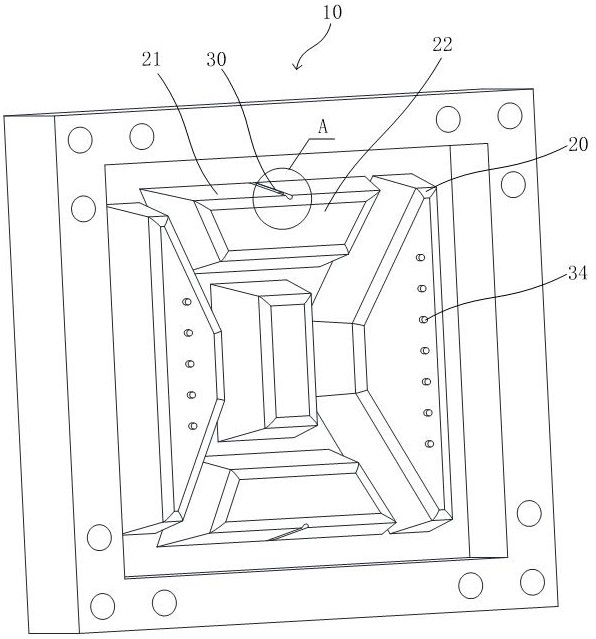

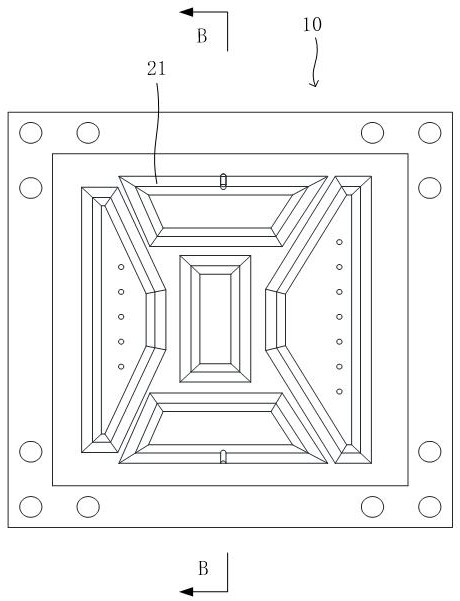

[0042] see Figure 1-Figure 5 , which is a schematic structural view of a mold device 100 for plastic molding provided in Embodiment 1 of the present invention. The mold device 100 includes, for example, a first mold 10 , a second mold and a stripping assembly 30 . Specifically, the first mold 10 is provided with a core 20; the second mold cooperates with the first mold 10 to form an injection molding space, and the injection molding space is used for injection molding of injection molded parts.

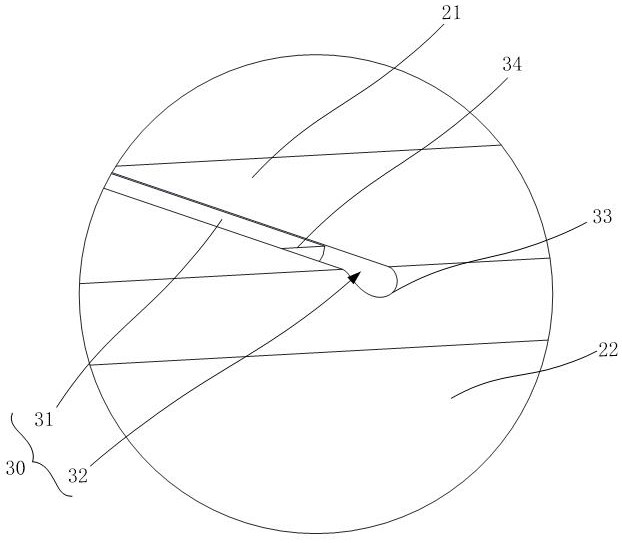

[0043] Further, the demoulding assembly 30 is disposed on the outer surface 22 of the core 20 , and the demoulding assembly 30 includes at least one chute 32 and at least one movable rod 31 , for example. At least one chute 32 is provided in the core 20, and a first opening 33 is formed on the outer surface 22 of the core 20; at least one movable rod 31 is telescopically arranged in the corresponding chute 32, wherein the movable rod 31 includes The abutting end 34 is used for abut...

Embodiment 2

[0046] combine Figure 1-5 The difference between the second embodiment and the first embodiment above is that the mold device 100 in the second embodiment is provided with an air blowing assembly, specifically, the air blowing assembly is arranged on the outer surface 22 of the core 20, and the The blowing component is provided with a plurality of blowing ports.

[0047] In a specific embodiment, the efficiency of demoulding is improved by synergizing the blowing component and the demoulding component 30 . Specifically, in the prior art, in the technical solution for demoulding, the use of the blowing component for demoulding has occurred, but there are many problems in using the blowing component alone to achieve the demoulding effect, For example, it is difficult to adjust the blowing force of the blowing assembly according to the degree of cooperation between each injection molded part and the mold device 100. The injection molded parts are directly blown off from the co...

Embodiment 3

[0063] see Figure 6 , which is a schematic structural diagram of an injection molding machine 200 for plastic processing provided by Embodiment 3 of the present invention. The injection molding machine 200 includes, for example, the mold device 100 as described in the first embodiment above, and / or includes the content as described in the second embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com