Modified graphene oxide anticorrosion coating and preparation method thereof

An anti-corrosion coating and graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as the compatibility of agglomerated epoxy resins, and achieve uniform dispersion, good impact resistance, and improved impact resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

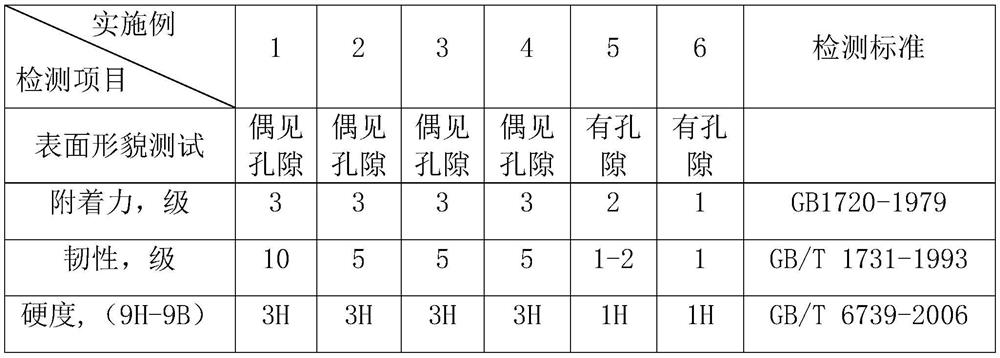

Examples

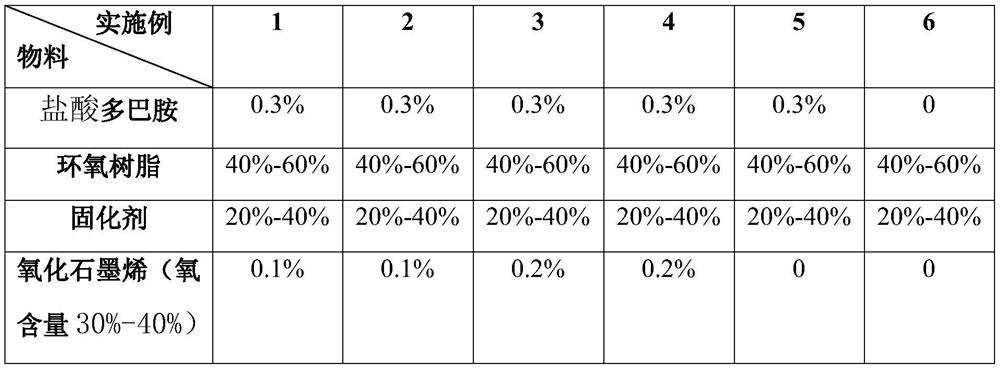

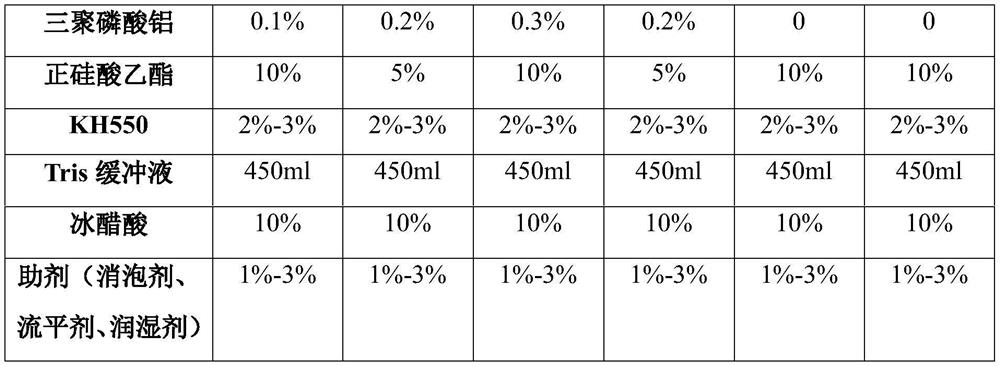

Embodiment 1 to 6

[0024] The preparation method of embodiment 1 to 6 is:

[0025] Preparation of KH550 modified SiO 2 @AlH 2 P 3 o 10 Composite material: take AlH 2 P 3 o 10 , disperse it in the ethanol solution of deionized water, then add tetraethyl orthosilicate, add dropwise glacial acetic acid, adjust the pH to 4±1, then stir on a magnetic stirrer for 40±10min, and then mix the stirred The liquid was transferred into the reaction kettle, and the hydrothermal reaction was carried out at 120 ± 10 ° C for 6 ± 1 h. The reacted product was washed with deionized water until it was neutral, and then dried in vacuum to obtain SiO 2 @AlH 2 P 3 o 10 Composite material; SiO 2 @AlH 2 P 3 o 10 The composite material is uniformly dispersed in absolute ethanol by ultrasonic; the temperature is raised to 50±5°C in a water bath, and KH550 silane coupling agent is added, and magnetically stirred at 50±5°C for 6±1h; after the system temperature is cooled to room temperature, use deionized Water...

Embodiment 1

[0037] A kind of preparation of modified graphene oxide anticorrosion paint, wherein each material consumption is as follows:

[0038] Dopamine Hydrochloride 0.3g

[0039] Graphene oxide 0.1g

[0040] Tris buffer 450ml

[0041] Aluminum tripolyphosphate (AlH 2 P 3 o 10 )0.1g

[0042] Orthoethyl silicate (TEOS) 10g

[0043] Glacial acetic acid solution 10ml

[0044] Silane coupling agent (KH550) 2ml

[0045] Epoxy resin: 60g

[0046] Curing agent: 40g

[0047] Defoamer: 0.3g

[0048] Leveling agent: 0.8g

[0049] Wetting agent: 0.8g

[0050] Concrete preparation method comprises the following steps:

[0051] (1) Take 0.1g AlH 2 P 3 o 10 , disperse it in 75ml of ethanol solution of deionized water, then add 10g of ethyl orthosilicate, dropwise add 10ml of glacial acetic acid, adjust the pH to 5, put the mixed solution on a magnetic stirrer and stir for 30min, then stir well The mixed solution was transferred into a 100ml reaction kettle, and subjected to hydroth...

Embodiment 2

[0056] A kind of preparation of modified graphene oxide anticorrosion paint, wherein each material consumption is as follows:

[0057] Dopamine Hydrochloride 0.3g

[0058] Graphene oxide 0.1g

[0059] Tris buffer 450ml

[0060] Aluminum tripolyphosphate (AlH 2 P 3 o 10 )0.2g

[0061] Orthoethyl silicate (TEOS) 5g

[0062] Glacial acetic acid solution 10ml

[0063] Silane coupling agent (KH550) 2ml

[0064] Epoxy resin: 60g

[0065] Curing agent: 40g

[0066] Defoamer: 0.3g

[0067] Leveling agent: 0.8g

[0068] Wetting agent: 0.8g

[0069] Concrete preparation method comprises the following steps:

[0070] (1) Take 0.2g AlH 2 P 3 o 10 , disperse it in 75ml of ethanol solution of deionized water, then add 10g of ethyl orthosilicate, dropwise add 10ml of glacial acetic acid, adjust the pH to 5, put the mixed solution on a magnetic stirrer and stir for 30min, then stir well The mixed solution was transferred into a 100ml reaction kettle, and subjected to hydrotherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com