Shock-absorbing and heat-dissipating equipment for a refrigerant reducer

A reducer and refrigerant technology, applied in cooling/ventilation devices, mechanical equipment, electromechanical devices, etc., can solve problems that do not involve energy conservation and environmental protection, and achieve the effect of dispersing impact and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

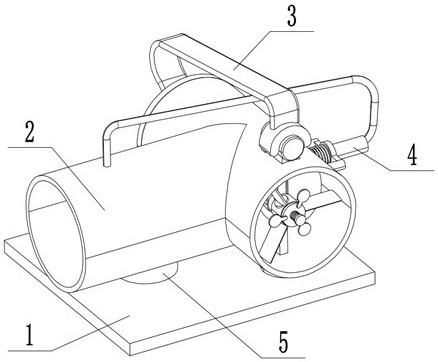

[0019] Example: such as Figure 1-11 The shock-absorbing and heat-dissipating equipment of a refrigerant reducer shown includes a fixed base plate 1, a pipeline 2, a power generating mechanism 3, a reducing mechanism 4, and a shock-absorbing pad 5. The pipeline 2 is arranged on the fixed base plate 1 .

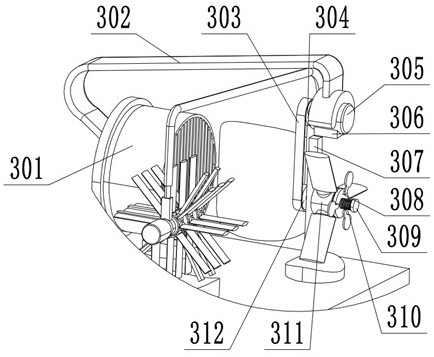

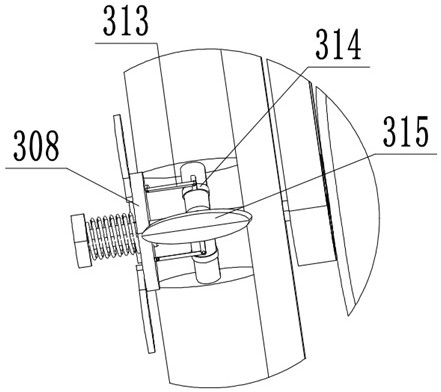

[0020] Such as figure 2 , image 3 The power generating mechanism 3 shown includes a heat sink 301, a copper plate 302, a belt 303, a transmission upper pulley 304, a cooling motor 305, a motor seat 306, a fixed base 307, a rotating plate 308, an active rod 309, a cooling spring 310, an outer ring sleeve 311, Pass down the pulley 312, the small connecting rod 313, the collar 314, and the rotating paddle 315; the cooling tube 301 is arranged on the pipeline 2, and one end of the copper plate 302 is installed on the cooling tube 301, and the other end is installed on the cooling motor 305, and the cooling motor 305 Fixedly installed on the motor base 306, the motor base 306 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com