Automatic slurry delivery system and its construction method applied to large hydropower stations

A slurry delivery and automatic technology, which is applied in infrastructure engineering, construction, multiple fluid ratio control, etc., can solve the problems of time-consuming, labor-intensive, poor practicability, and high cost, and achieve the effects of convenience for construction personnel, high accuracy, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

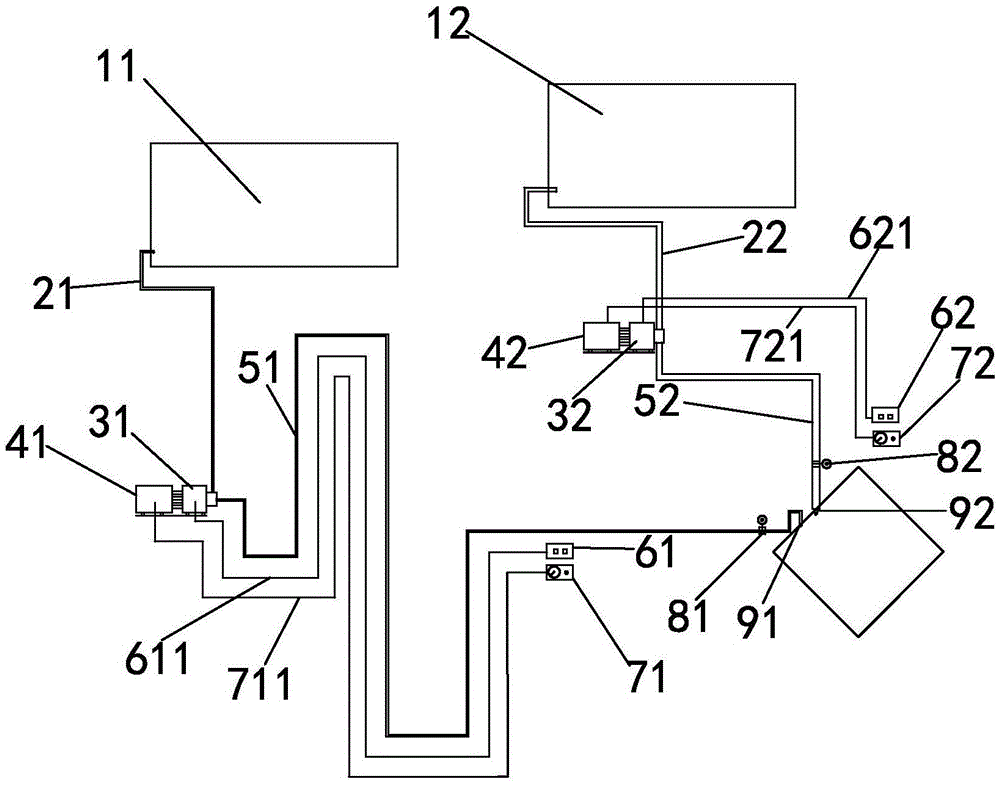

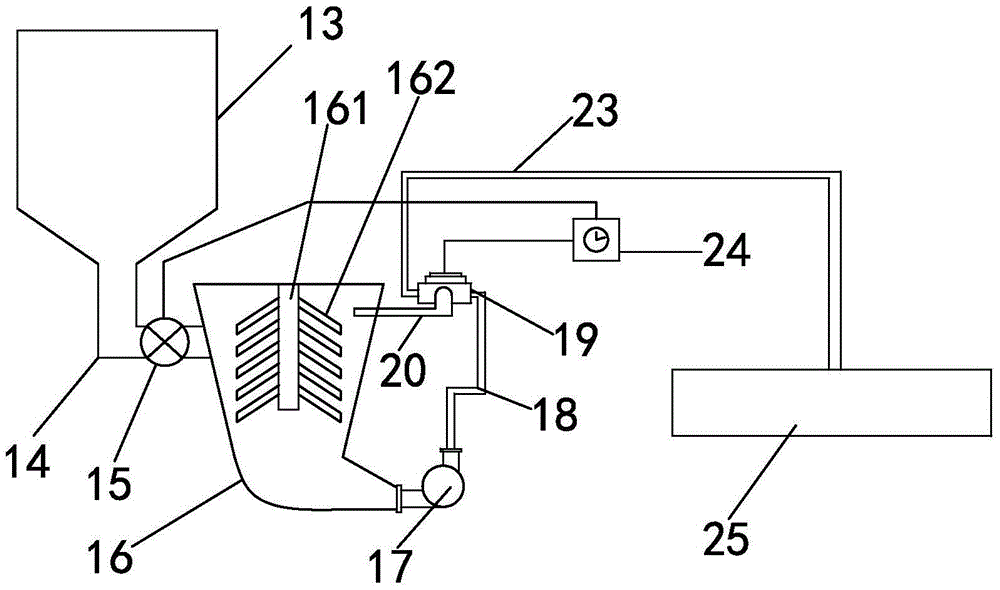

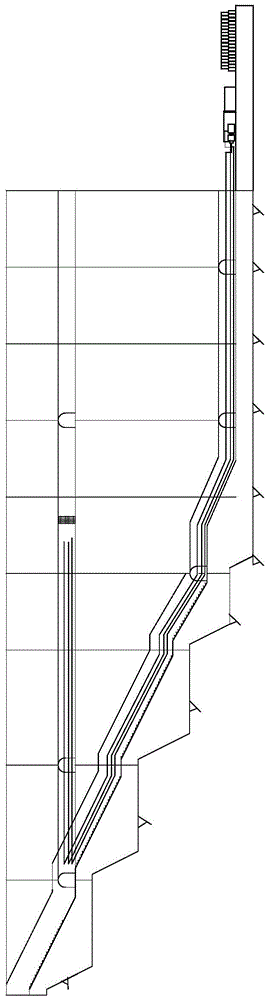

[0041] Such as figure 1 As shown in FIG. 5 , the automatic pulp conveying system includes a pulp conveying system and an automatic pulp making system. The pulp conveying system includes a collection box, and the collection box includes a first collection box 11 and a second collection box 12 . Epoxy base material can be filled in the first collection box 11, the first collection box 11 is connected with the first slurry suction pipe 21, the other end of the first slurry suction pipe 21 is connected with the input end of the first electric gear pump 31, the second The output end of an electric gear pump 31 is connected to the first pulp delivery pipe 51, and the other end of the first slurry delivery pipe 51 is connected to the automatic pulp making system. The first electric gear pump 31 provides power for the process of transporting the epoxy base material slurry to ensure that the epoxy base material slurry can be smoothly transported to the height of the dam body. A first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com