Thermal power plant air pre-heater and using method thereof

An air preheater and thermal power plant technology, applied in chemical instruments and methods, separation methods, combustion methods, etc., can solve the problems of polluting air, affecting the boiler inlet temperature, and unfavorable full combustion of boiler fuel, and achieving convenient disassembly and installation. , Improve heating efficiency and facilitate maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

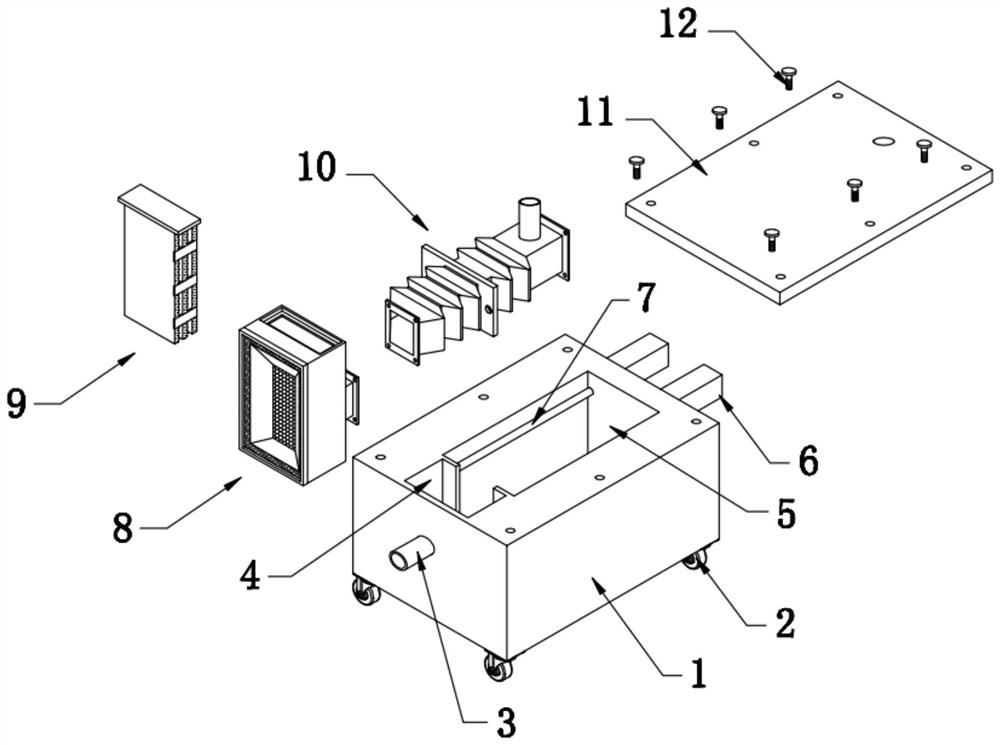

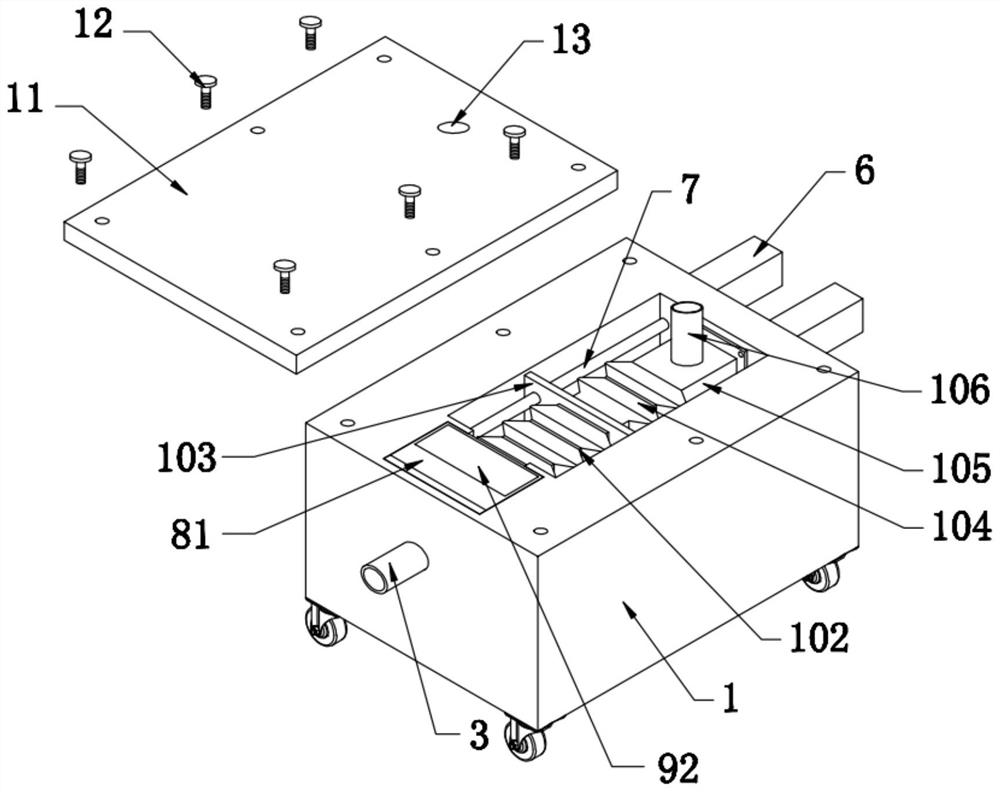

[0024] Embodiment 1: the present invention provides such as Figure 1-3 A thermal power plant air preheater, including a moving box 1, the upper end of the moving box 1 is provided with a first installation cavity 4 and a second installation cavity 5 in sequence from front to back, and the first installation cavity 4 is installed There is a filtering device 8, and an air mixing device 10 is installed in the second installation cavity 5;

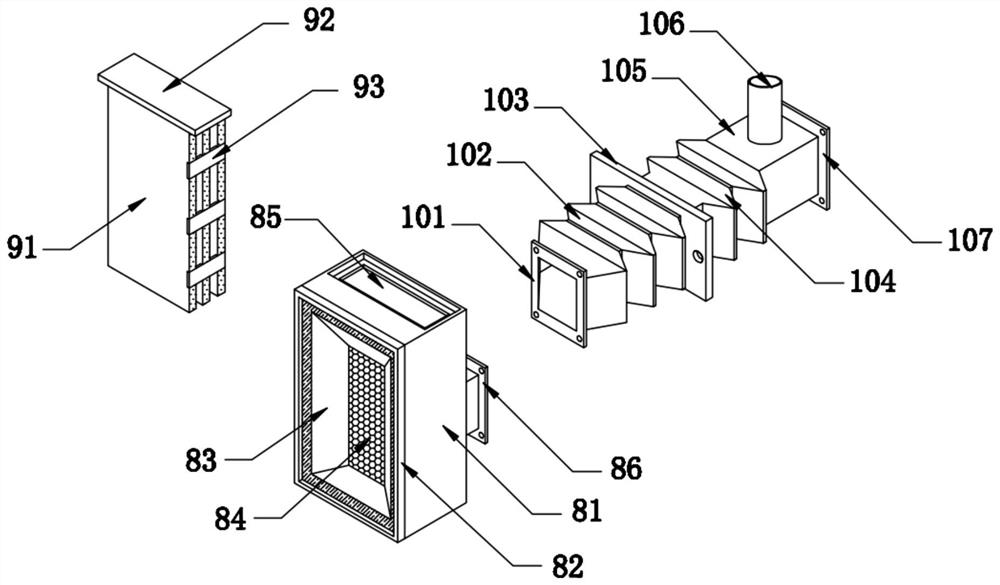

[0025] The filter device 8 includes an air intake box 81 inserted into the first installation cavity 4 and a filter mechanism 9 installed inside the air intake box 81. The front end middle part of the air intake box 81 is provided with an air intake net 84. A square exhaust pipe 86 is provided in the middle of the rear end of the gas box 81, and the filter mechanism 9 includes several layers of filter plates 91, and reinforcement plates 93 connected to the sides of the several layers of filter plates 91;

[0026] The air mixing device 10 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com