Active heat dissipation high-voltage test vehicle

A high-voltage test and active heat dissipation technology, which is applied to motor vehicles, goods transport vehicles, lighting and heating equipment, etc., can solve the problems of long power recovery time, no active heat dissipation equipment, and long waiting time, etc., to achieve fast The effect of heat dissipation and cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

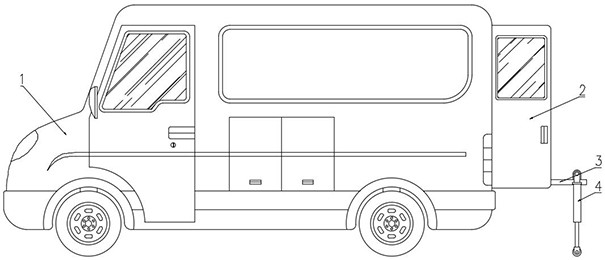

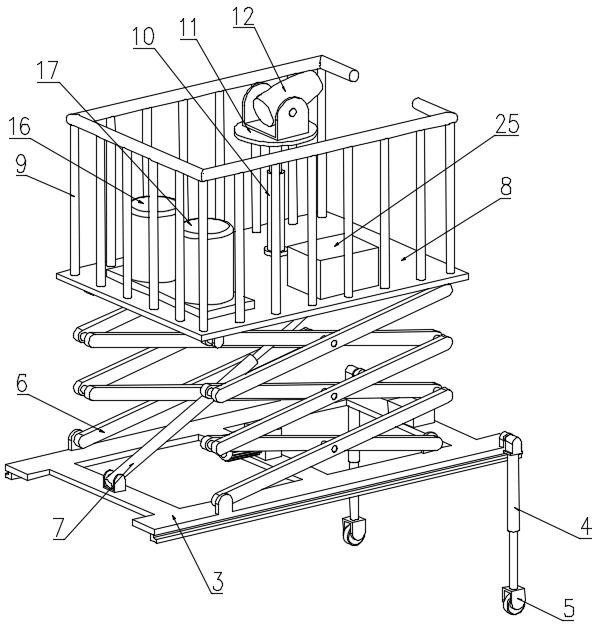

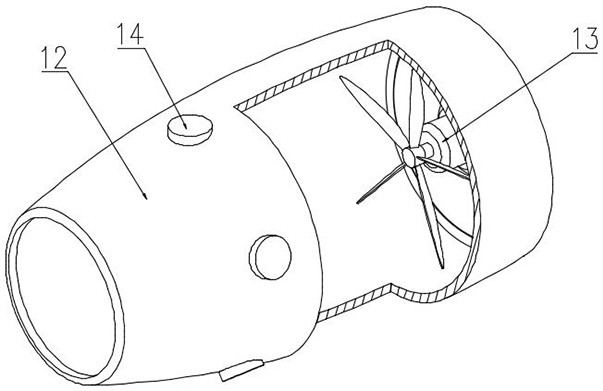

[0043] see Figure 1-11 , an active heat dissipation type high-voltage test vehicle, comprising a test vehicle body 1, a tailgate 2 is provided at the tail of the test vehicle body 1, and a movable seat 3 located inside the test vehicle body 1, and a lifting part is arranged on the movable seat 3, And the lifting part is provided with a platform 8, the platform 8 is provided with a cylindrical body 12, a first liquid storage tank 16 and a second liquid storage tank 17, and the first liquid storage tank 16 and the second liquid storage tank 17 are respectively filled with For water and liquid nitrogen, cylinder body 12 is movably connected with platform 8 by support assembly, and cylinder body 12 is provided with blower fan 13 for spraying water mist and nitrogen, and the top of platform 8 is provided with storage box 25, and storage box 25 is provided with a winding assembly for winding the pipe, and the inner front end of the cylinder 12 is provided with a spout assembly for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com