Metal surface defect detection method based on U-NET convolutional neural network

A convolutional neural network and U-NET technology, which is applied in the field of image processing and analysis, can solve the problems of high labor intensity, low classification accuracy and low detection speed of the visual inspection method, so as to eliminate the interference of human subjective factors and save labor costs. , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing

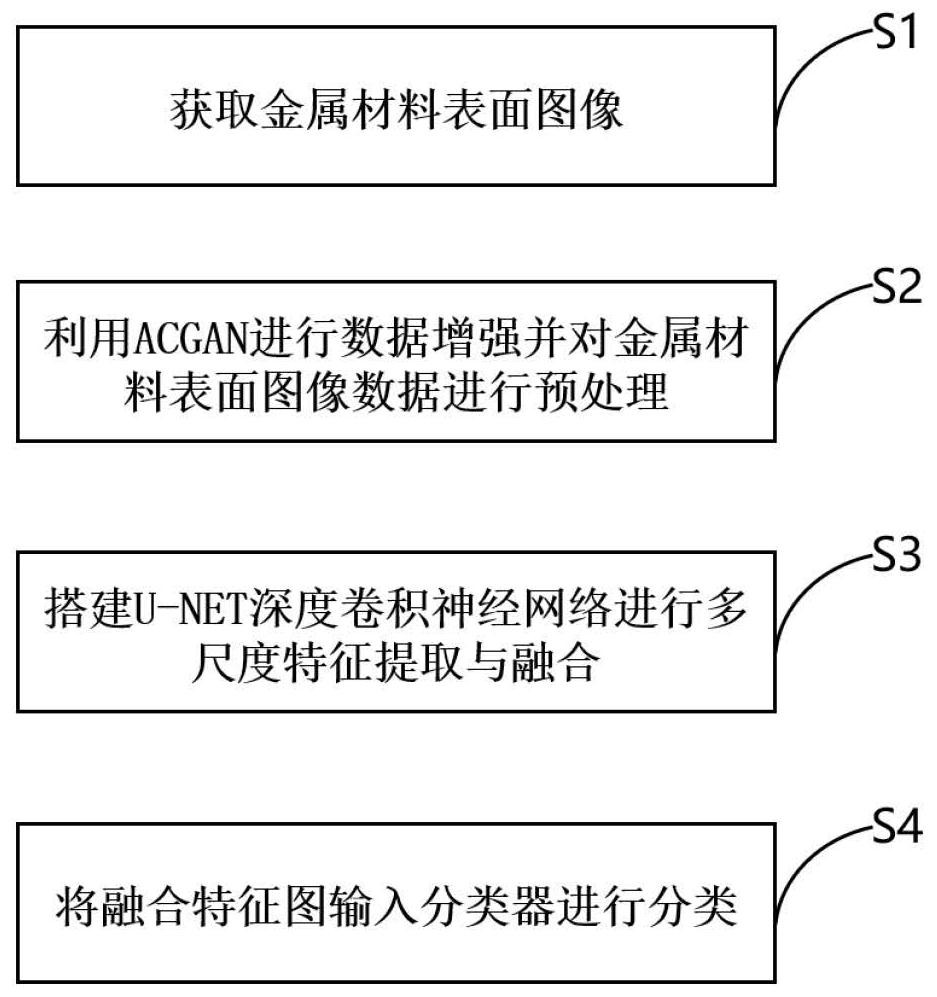

[0019] like figure 1 As shown, the technical problem to be solved by the present invention is to provide a metal material surface quality detection method based on deep learning network, which improves the accuracy and efficiency of metal material surface quality detection.

[0020] S1 acquires image data of metal materials; the workpiece to be tested is placed on the detection platform, and under a stable and uniform lighting environment, the image data of the outer surface of the workpiece to be tested is obtained through the industrial camera on the detection platform.

[0021] S2 uses the ACGAN image generation network to perform data enhancement on a small number of defect type images, and preprocess the acquired image data. ,

[0022] S3 builds an improved U-NET semantic segmentation network, uses a deep convolutional neural network to extract features from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com