Anti-counterfeit label and manufacturing process thereof

A production process and technology of anti-counterfeiting labels, applied in the field of anti-counterfeiting codes, can solve problems such as weak anti-counterfeiting, easy to be counterfeited, and failure to achieve anti-counterfeiting effects, achieve strong adhesion, improve anti-counterfeiting effects, and have high use value and practical value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

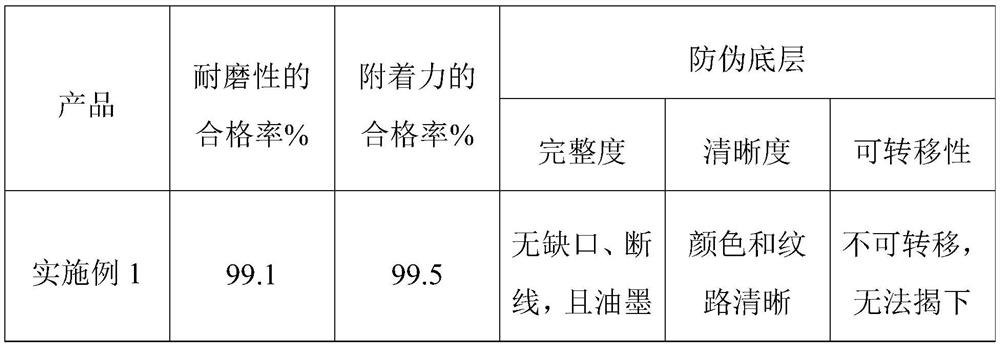

Embodiment 1

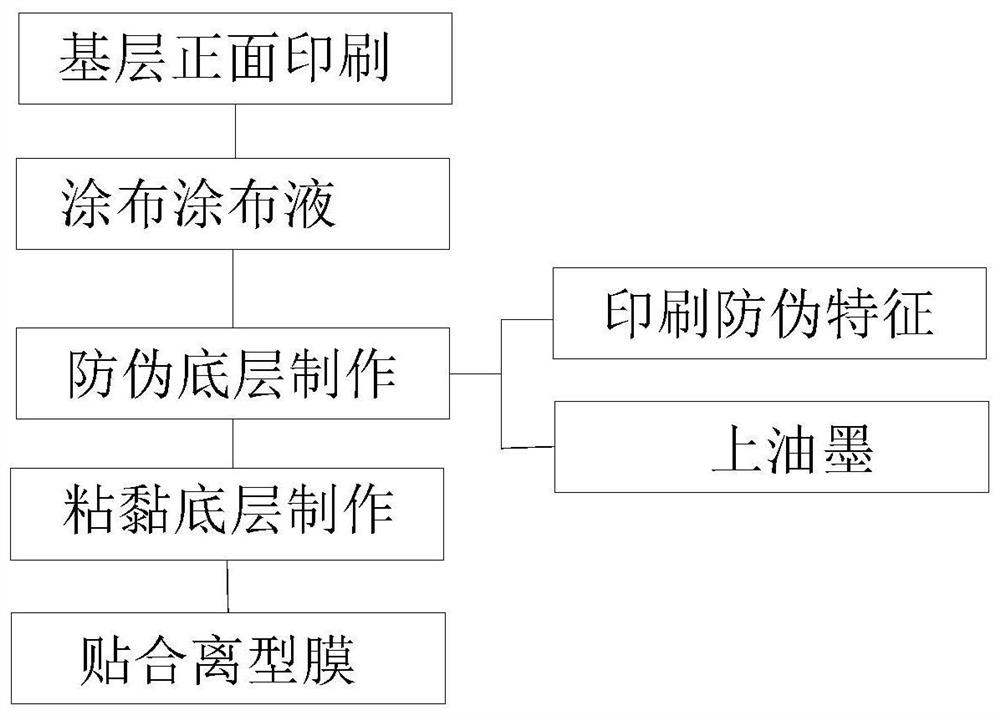

[0043] Please refer to figure 1 , figure 1 Shown is a manufacturing process of an anti-counterfeiting label provided in this embodiment, which includes the following steps:

[0044] 1) Print a printing layer with two-dimensional codes and product information on the front of the substrate by offset printing, and coat the printing layer with varnish to make an anti-scratch layer.

[0045] 2) Coat a layer of varnish on the back of the substrate, then coat the coating solution, dry it under the conditions of infrared drying temperature of 50°C and hot air drying temperature of 100°C, and then print the anti-counterfeiting two-dimensional code on it , coated with white ink to prepare the anti-counterfeit bottom layer, and placed the anti-counterfeit bottom layer in a UV lamp box for curing. At this time, the power of the UV lamp was 7kw, and the curing time was 0.5s. And the above process links are all carried out in the flexo printing machine. The parameters of the flexo printin...

Embodiment 2

[0049] Please refer to figure 1 , figure 1 Shown is a manufacturing process of an anti-counterfeiting label provided in this embodiment, which includes the following steps:

[0050] 1) Print a printing layer with two-dimensional codes and product information on the front of the substrate by means of offset printing.

[0051] 2) Coat a layer of varnish on the back of the substrate, then coat the coating solution, dry it under the conditions of infrared drying temperature of 45°C and hot air drying temperature of 60°C, and then print anti-counterfeiting two-dimensional code on it , coated with white ink to prepare the anti-counterfeit bottom layer, and placed the anti-counterfeit bottom layer in a UV light box for curing. At this time, the power of the UV lamp was 5kw, and the curing time was 5s. And the above process links are all carried out in the flexo printing machine. The parameters of the flexo printing machine are as follows: the number of mesh lines is 160LPI, the mes...

Embodiment 3

[0055] Please refer to figure 1 , figure 1 Shown is a manufacturing process of an anti-counterfeiting label provided in this embodiment, which includes the following steps:

[0056] 1) Print a printing layer with two-dimensional codes and product information on the front of the substrate by offset printing, and coat the printing layer with varnish to make an anti-scratch layer.

[0057] 2) Coat a layer of varnish on the back of the substrate, then coat the coating solution, dry it under the conditions of infrared drying temperature of 60°C and hot air drying temperature of 80°C, and then print anti-counterfeiting two-dimensional code on it , coated with white ink to prepare the anti-counterfeit bottom layer, and placed the anti-counterfeit bottom layer in a UV light box for curing. At this time, the power of the UV lamp was 10kw, and the curing time was 0.3s. And the above process links are all carried out in the flexo printing machine. The parameters of the flexo printing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com