Method for removing electrolytic capacitor of boost converter and modified boost converter

A technology of boost converter and electrolytic capacitor, applied in the field of boost converter, can solve the problems of low reliability, difficulty of boost converter to meet industrial application, short service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

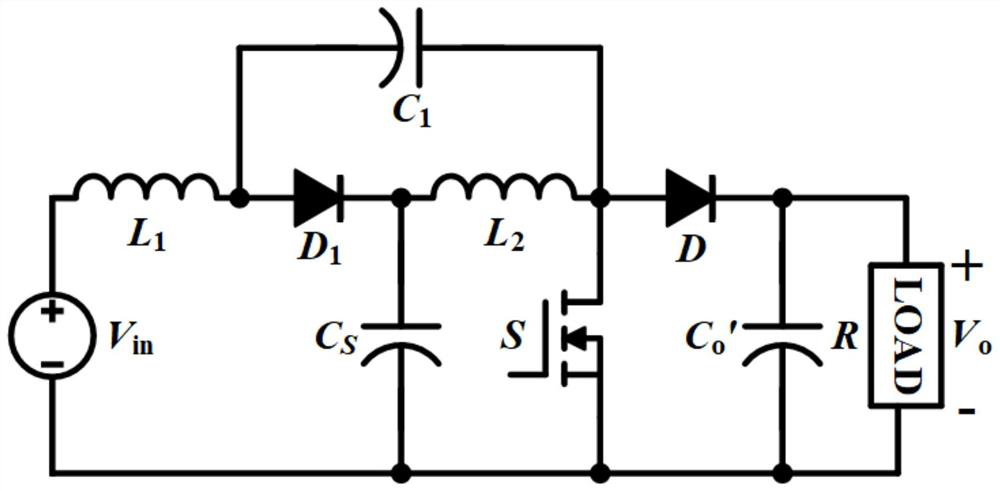

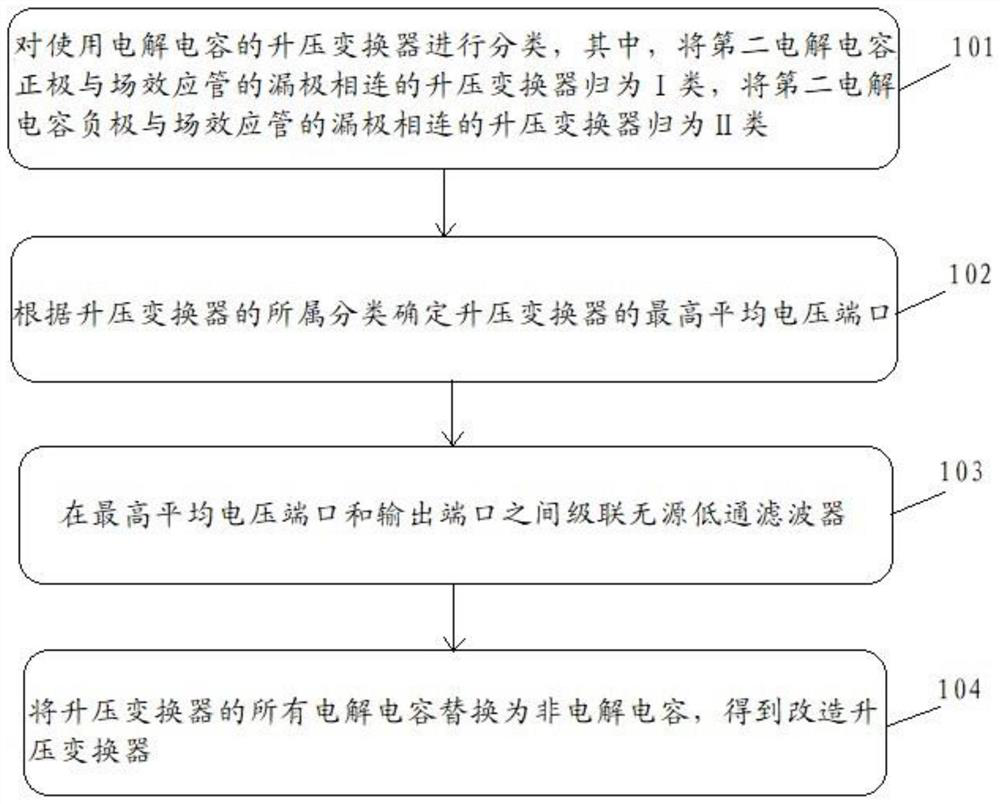

[0042] For ease of understanding, the embodiment of the present invention uses a quasi-Z source boost converter as an example to illustrate the process of removing the electrolytic capacitor of the boost converter. see Figure 2 to Figure 5 , an embodiment of a method for removing electrolytic capacitors of a boost converter provided by the present invention, the method is applied to include the first electrolytic capacitor C 1 , the second electrolytic capacitor C s , the third electrolytic capacitor C' 0 , the first inductance L 1 , the second inductance L 2 , the first diode D, the second diode D 1 , the voltage source Vin, the switch tube S and the boost converter of the load R;

[0043] The first inductance L 1 One end is connected to the anode of the voltage source Vin, the first inductor L 1 The other end is connected to the second diode D 1 anode of the second diode D 1 The cathode of the second inductor L is connected 2 One end of the second inductor L 2 Th...

Embodiment 2

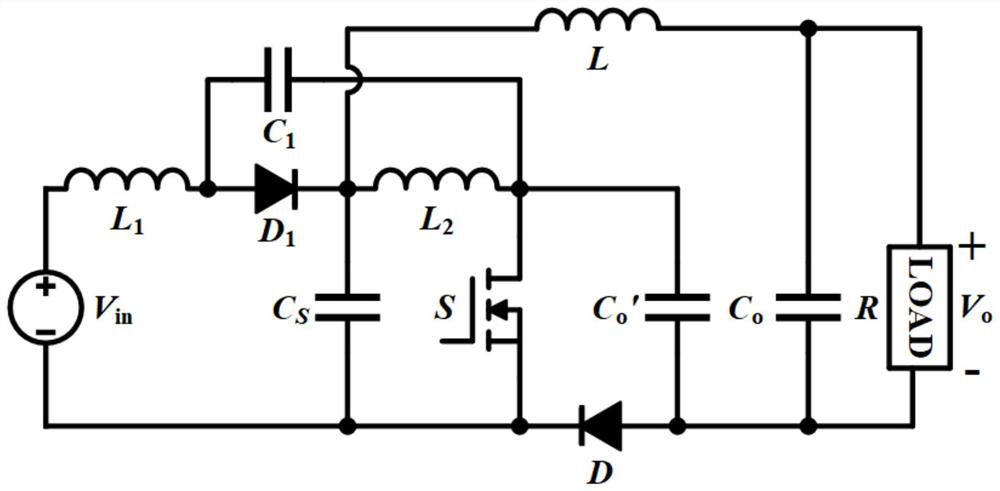

[0063] The present invention provides an embodiment of a modified boost converter. The modified boost converter in the embodiment of the present invention is improved by removing the electrolytic capacitor of the boost converter in Embodiment 1.

[0064] The formula for calculating the output voltage at the output port of the modified boost converter is:

[0065]

[0066] Among them, V o is the average output voltage, is the average capacitor voltage of the second electrolytic capacitor CS, is the average capacitor voltage of the third electrolytic capacitor C0, and D is the duty cycle of the field effect transistor.

[0067] The formula for calculating the output voltage ripple amplitude of the modified boost converter is:

[0068]

[0069] Among them, Δv o is the output voltage ripple amplitude, L is the inductance value of the passive low-pass filter inductor, C o is the capacitance value of the passive low-pass filter inductor, f s is the switching frequency ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inductance value | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Inductance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com