Side dish adding mechanism and working method

A working method and technology for side dishes, applied in the field of kitchen supplies, can solve the problems of adding and destroying side dishes, and achieve the effects of low difficulty, low failure rate and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

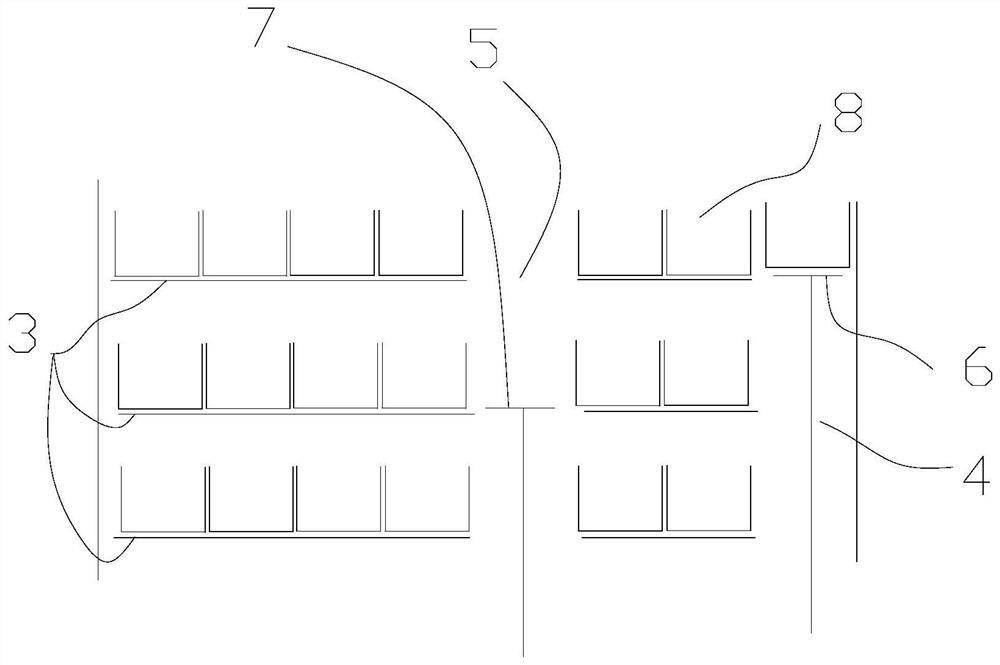

[0045] like figure 1 , the first channel 4 or the second channel 5 is set in the middle of the slideway 3, and the pick-and-place material level 8 is set at a certain position on the slideway 3, through the first lifting pallet 6, the second lifting pallet 7 and the pushing The mechanism pushes the material grid 2 filled with side dishes to the pick-and-place material position 8.

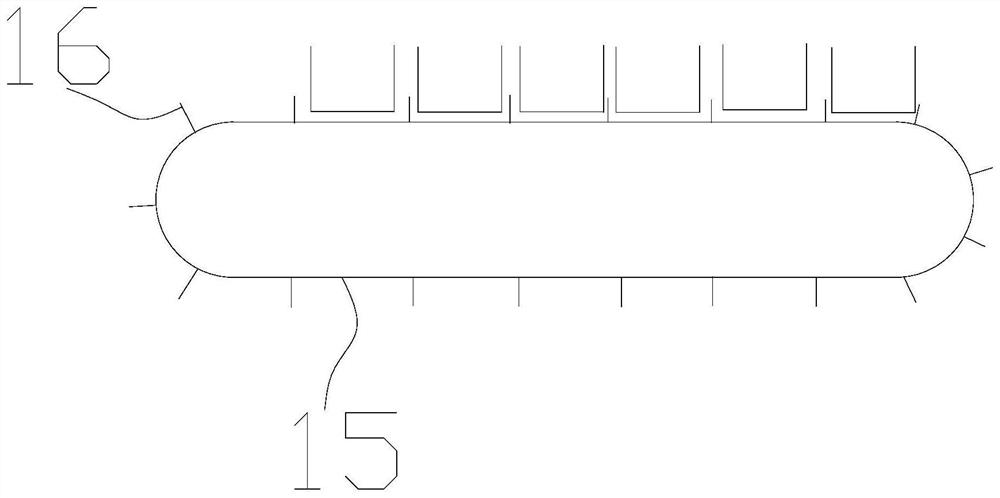

[0046] When the first channel 4 or the second channel 5 is located in the middle of the slideway 3, if the pushing mechanism adopts the form of a cylinder, etc., the installation is difficult and interference is likely to occur. The pushing of the material grid 2 can be in the form of a fixed push plate 16 on the chain 15 ,like figure 2 , directly installed above or below the slideway 3.

Embodiment 2

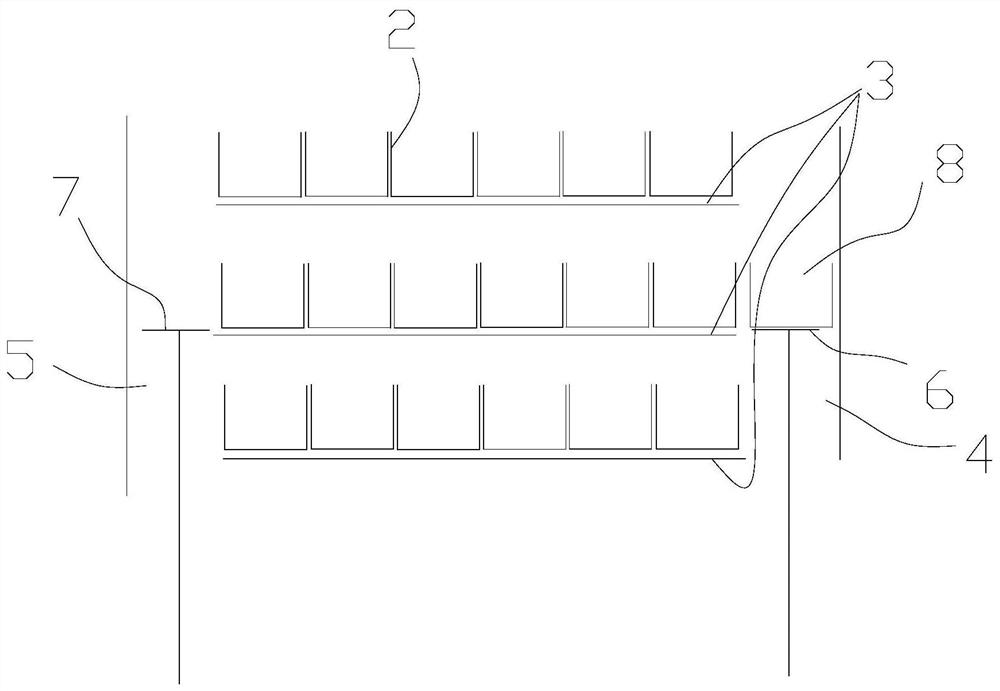

[0048] like image 3 , the first passage 4 is arranged at the first end of the slideway 3 , and the second passageway 5 is arranged at the second end of the slideway 3 . The number of slideway 3 layers is 3 layers and above, and the pick-and-place material level 8 is set at the intersection of the extension area of the first channel 4 and the middle layer slideway 3, so that the passages of the upper layer and the lower layer can be taken and placed according to the layer. 8 Push the material grid 2 containing side dishes, such as pushing the upper layer first, and then pushing the lower layer.

Embodiment 3

[0050] As an embodiment of the present invention, the slideway 3 layers are two layers, such as Figure 4 , the pick-and-place material level 8 is set at the intersection of the first channel 4 and the extension area of the upper slideway 3 .

[0051] like Figure 5-6 , the first lifting pallet 6 and the second lifting pallet 7 are all connected with a lifting cylinder 9, and the first lifting pallet 6 and the second lifting pallet 7 are fixed with the piston rod of the lifting cylinder 9 at the corresponding position. The pushing mechanism that is positioned at the slideway 3 of upper floor comprises the first pushing cylinder 10 and the first pushing plate 11 that is fixed with the piston rod of the first pushing cylinder 10, and the pushing mechanism that is positioned at the slideway 3 of lower floor comprises the second pushing cylinder 12 and with The second push plate 13 that the piston rod of the second push cylinder 12 is fixed, the first push cylinder 10 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com