Healthy multifunctional indoor purification material and preparation method thereof

A technology for multi-functional chambers and purifying materials, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of complex preparation methods and limited effects, and achieve the effect of promoting health and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

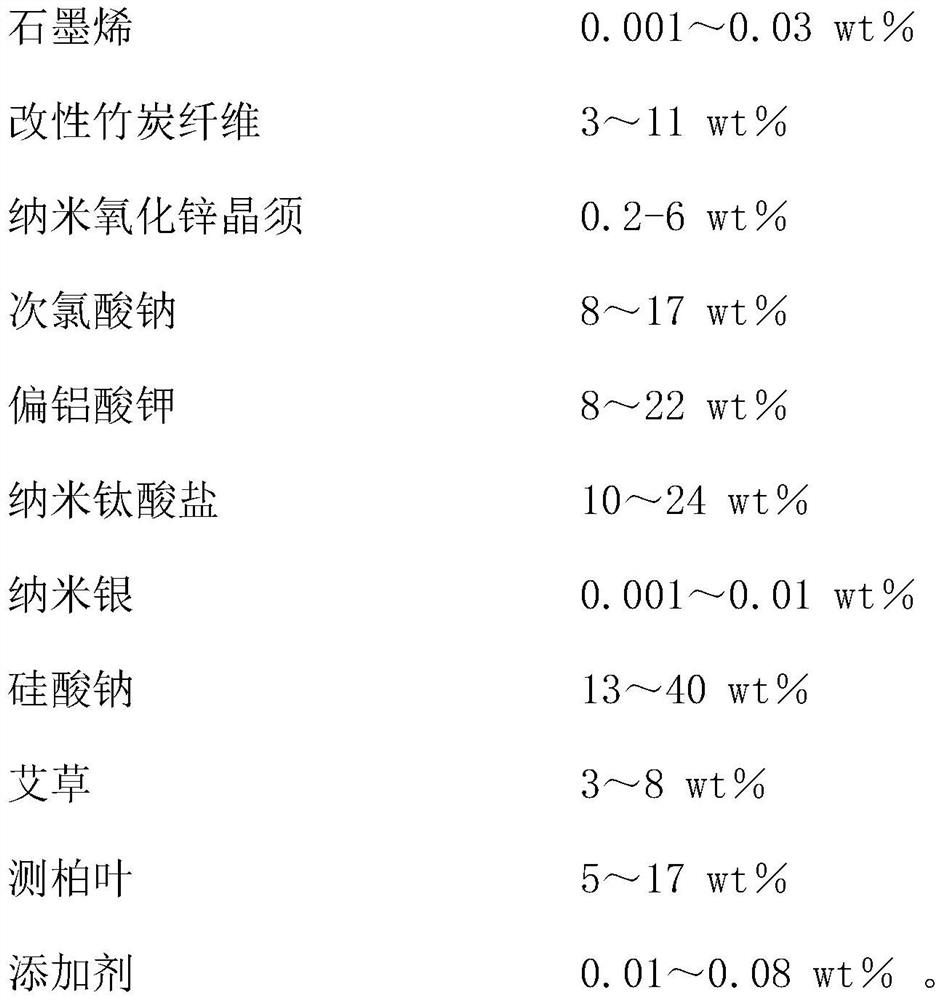

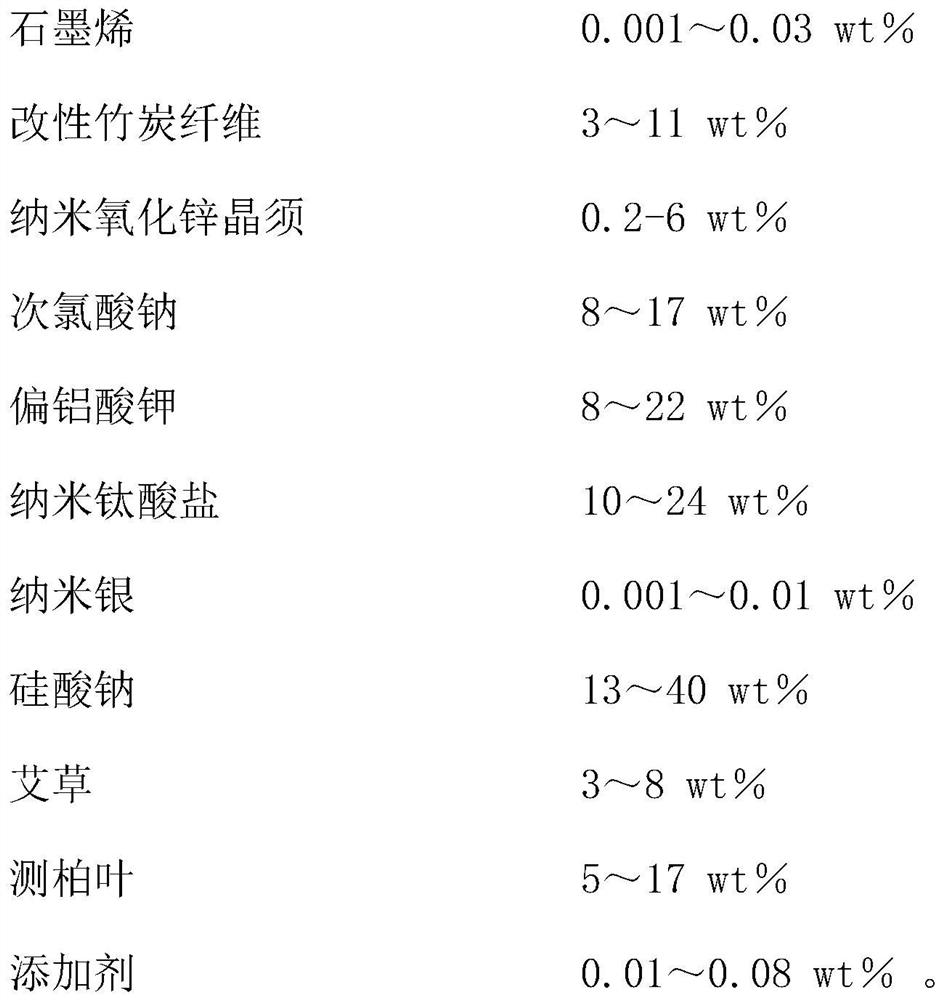

Method used

Image

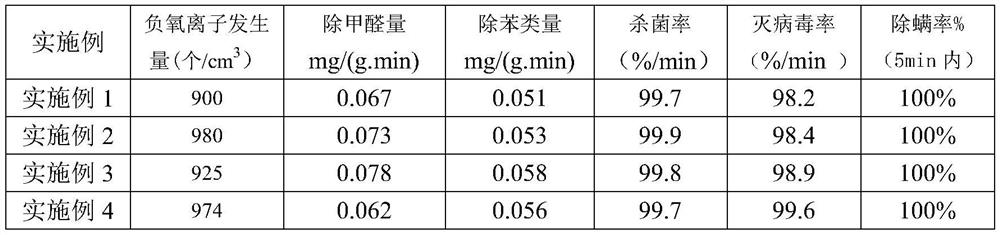

Examples

Embodiment 1

[0021] (1) Add 0.001g additive, 22g potassium metaaluminate and 8g sodium hypochlorite successively to 60g water to be fully dissolved, then successively add 0.005g graphene, 6g nano zinc oxide whiskers, 0.001g nano silver, 10g nano iron titanate (average particle size 30nm), ultrasonic dispersion for 6min, to obtain dispersion liquid A.

[0022] (2) 3g of modified bamboo charcoal fibers are added to material A and ultrasonically dispersed for 10min, then 6g of wormwood and 5g of Arborvitae leaves are added, and ultrasonically dispersed for 6min to obtain material B.

[0023] (3) Add 40 g of sodium silicate to material B and stir to make it evenly mixed to obtain material C.

[0024] (4) Heat the material C in a vacuum drying oven at a heating temperature of 70° C. and a heating time of 80 min, and then take it out to obtain the material.

Embodiment 2

[0026] (1) Add 0.03g additive, 14g potassium metaaluminate and 14g sodium hypochlorite successively to 80g water to be fully dissolved, then successively add 0.002g graphene, 5g nano zinc oxide whisker, 0.007g nano silver, 20g nano iron titanate (average particle size 40nm) and ultrasonic dispersion for 8min to obtain dispersion liquid A.

[0027] (2) 7g of modified bamboo charcoal fibers were added to material A and ultrasonically dispersed for 12min, then 3g of wormwood and 17g of Arborvitae leaves were added, and material B was obtained by ultrasonic dispersion for 8min.

[0028] (3) Add 20 g of sodium silicate to material B and stir to make it evenly mixed to obtain material C.

[0029] (4) Heat the material C in a vacuum drying oven at a heating temperature of 75° C. and a heating time of 70 min, and then take it out to obtain the material.

Embodiment 3

[0031] (1) Add 0.006g additive, 8g potassium metaaluminate and 17g sodium hypochlorite to 100g water to fully dissolve, then add 0.007g graphene, 5g nano zinc oxide whisker, 0.005g nano silver, 24g nano nickel titanate (average particle size) successively 50 nm) and ultrasonically dispersed for 7 min to obtain dispersion A.

[0032] (2) 11g of modified bamboo charcoal fibers are added to material A and ultrasonically dispersed for 14min, then 6g of wormwood and 16g of arborvitae leaves are added, and ultrasonically dispersed for 7min to obtain material B.

[0033] (3) Add 13 g of sodium silicate to material B and stir to make it evenly mixed to obtain material C.

[0034] (4) Heat the material C in a vacuum drying oven at a heating temperature of 80° C. and a heating time of 60 min, and then take it out to obtain the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap